Preparation method of modified porous silicon material loaded with diethyl succinate and application thereof to carbon dioxide capturing and sealing storage

A technology of diethyl succinate and carbon dioxide, applied in separation methods, other chemical processes, chemical instruments and methods, etc., can solve the problems of large volume of adsorbents, high separation components, high energy consumption, etc. The effect of reducing volatility and increasing specific surface area

- Summary

- Abstract

- Description

- Claims

- Application Information

AI Technical Summary

Problems solved by technology

Method used

Image

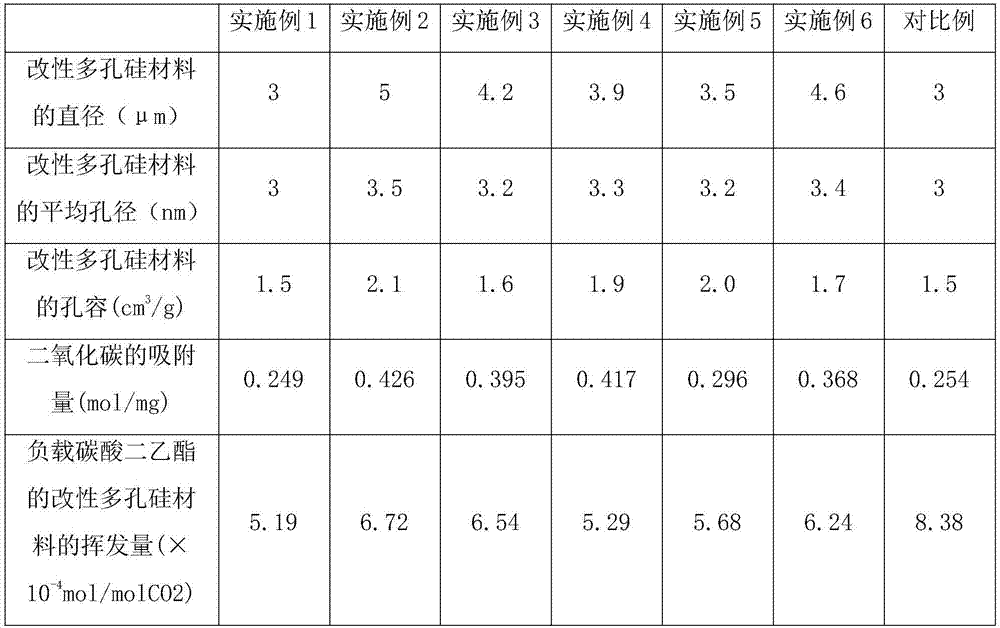

Examples

Embodiment 1

[0025] (1) Add polyoxyethylene and magnesium chloride with a mass ratio of 1:0.2 to 10vol.% hydrochloric acid aqueous solution, seal and stir until completely dissolved, add tetraethyl orthosilicate with a volume ratio of 2-:1 to hydrochloric acid, Heat and stir at 40°C for 24h, vacuum dry at 100°C for 36h, cool naturally, filter and wash, and sinter at 450°C for 6h to obtain a modified porous silicon material.

[0026] (2) Add ethanol to the mixture of diethyl carbonate and diethyl succinate with a molar percentage of 80%: 20%, wherein the volume ratio of the mixture of diethyl carbonate and diethyl succinate to ethanol is 3:10 After mixing evenly, add the modified porous silicon material, sonicate for 30min, stir and reflux at 80°C for 2h, and bathe in water at 70°C until all the ethanol volatilizes to obtain a modified porous silicon material loaded with diethyl succinate, in which succinic acid is loaded The loading rate of the mixture of diethyl carbonate and diethyl succ...

Embodiment 2

[0028] (1) Add polyoxyethylene and magnesium chloride with a mass ratio of 1:0.3 to 20vol.% hydrochloric acid aqueous solution, seal and stir until completely dissolved, add tetraethyl orthosilicate with a volume ratio of 3:2 to hydrochloric acid, and Heating and stirring at 50°C for 24 hours, vacuum drying at 100°C for 48 hours, cooling naturally, filtering and washing, and sintering at 600°C for 24 hours to obtain a modified porous silicon material.

[0029] (2) Add ethanol to the mixture of diethyl carbonate and diethyl succinate with a molar percentage of 67%:43%, wherein the volume ratio of the mixture of diethyl carbonate and diethyl succinate to ethanol is 4:10 After mixing evenly, add the modified porous silicon material, sonicate for 30min, stir and reflux at 80°C for 2h, and bathe in water at 70°C until all the ethanol volatilizes to obtain a modified porous silicon material loaded with diethyl succinate, in which succinic acid is loaded The loading rate of the mixtu...

Embodiment 3

[0031] (1) Add polyoxyethylene and magnesium chloride with a mass ratio of 1:0.25 to 15vol.% hydrochloric acid aqueous solution, seal and stir until completely dissolved, add tetraethyl orthosilicate with a volume ratio of 2:2 to hydrochloric acid, and Heat and stir at 45°C for 24h, vacuum dry at 100°C for 40h, cool naturally, filter and wash, and sinter at 500°C for 12h to obtain a modified porous silicon material.

[0032] (2) Add ethanol to the mixture of diethyl carbonate and diethyl succinate with a molar percentage of 0%:100%, wherein the volume ratio of the mixture of diethyl carbonate and diethyl succinate to ethanol is 3.5:10 After mixing evenly, add the modified porous silicon material, sonicate for 30min, stir and reflux at 80°C for 2h, and bathe in water at 70°C until all the ethanol volatilizes to obtain a modified porous silicon material loaded with diethyl succinate, in which succinic acid is loaded The loading rate of the mixture of diethyl carbonate and diethy...

PUM

| Property | Measurement | Unit |

|---|---|---|

| diameter | aaaaa | aaaaa |

| pore size | aaaaa | aaaaa |

Abstract

Description

Claims

Application Information

Login to View More

Login to View More - R&D

- Intellectual Property

- Life Sciences

- Materials

- Tech Scout

- Unparalleled Data Quality

- Higher Quality Content

- 60% Fewer Hallucinations

Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2025 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com