Water-soluble polyamide, and preparation method and application thereof

A technology of water-soluble polyamide and reaction, which is applied in the direction of chemical instruments and methods, other chemical processes, adsorption water/sewage treatment, etc., and can solve the problem of complex synthetic methods of polyaspartic acid, inability to achieve economic benefits, and inability to obtain treatment effects And other problems, to achieve good solubility, low price, good hydrophilic effect

- Summary

- Abstract

- Description

- Claims

- Application Information

AI Technical Summary

Problems solved by technology

Method used

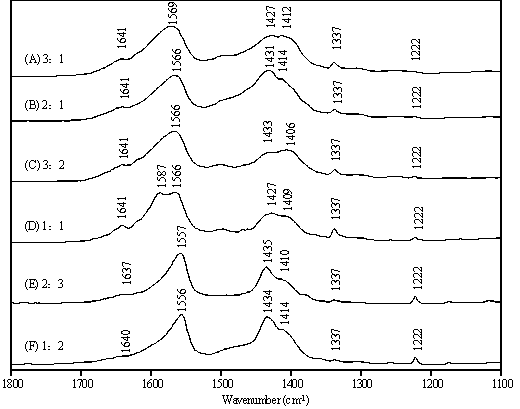

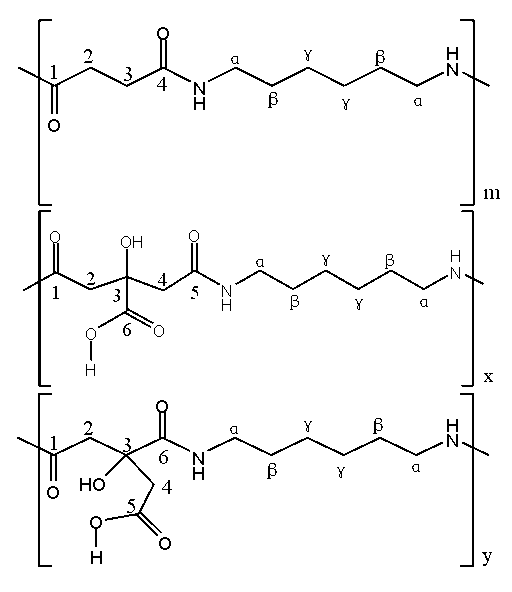

Image

Examples

Embodiment 1

[0037] According to the molar ratio of reactants TBC and DES 1:2, TBC17.2mmol, DES34.4mmol, 1,6-hexamethylenediamine 51.6mmol were mixed and added to a 250ml round bottom flask, heated and stirred at 60°C under vacuum for 6h to obtain For the mixed solution, pour the mixed solution into a 10cm*10cm polytetrafluoroethylene mold to spread it evenly. This is a prepolymer.

[0038] Place the prepolymer in a vacuum drying oven at 70°C and heat for 12 hours to obtain a colorless, transparent or milky white film. Continue heating the film at 160°C for 4 hours, then raise the temperature to 200°C and continue heating for 4 hours to obtain a reddish-brown solid film. It is the structural formula product 1 (polyamide-imide copolymer) in the above reaction equation.

[0039] Heat about 2g of polyamideimide sample in NaOH (pH=14) solution at 80°C for 8h, the sample is completely dissolved to obtain a light yellow clear solution, which is transferred to a rotary evaporator to remove water, a...

Embodiment 2

[0040] Embodiment 2: The method is the same as in Embodiment 1, but the molar ratio of TBC and DES is changed to 2:3.

Embodiment 3

[0041] Embodiment 3: The method is the same as in Embodiment 1, but the molar ratio of TBC and DES is changed to 1:1.

PUM

Login to View More

Login to View More Abstract

Description

Claims

Application Information

Login to View More

Login to View More - R&D

- Intellectual Property

- Life Sciences

- Materials

- Tech Scout

- Unparalleled Data Quality

- Higher Quality Content

- 60% Fewer Hallucinations

Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2025 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com