Preparation method of poly(butylene succinate)

A technology of polybutylene succinate and butanediol, which is applied in the field of biodegradable polyester preparation, can solve the problems of increased equipment cost and energy consumption, can not meet industrial applications well, and can improve molecular weight and Material properties, the effect of reducing energy consumption and organic solvent consumption, and reducing production costs

- Summary

- Abstract

- Description

- Claims

- Application Information

AI Technical Summary

Problems solved by technology

Method used

Image

Examples

Embodiment 1

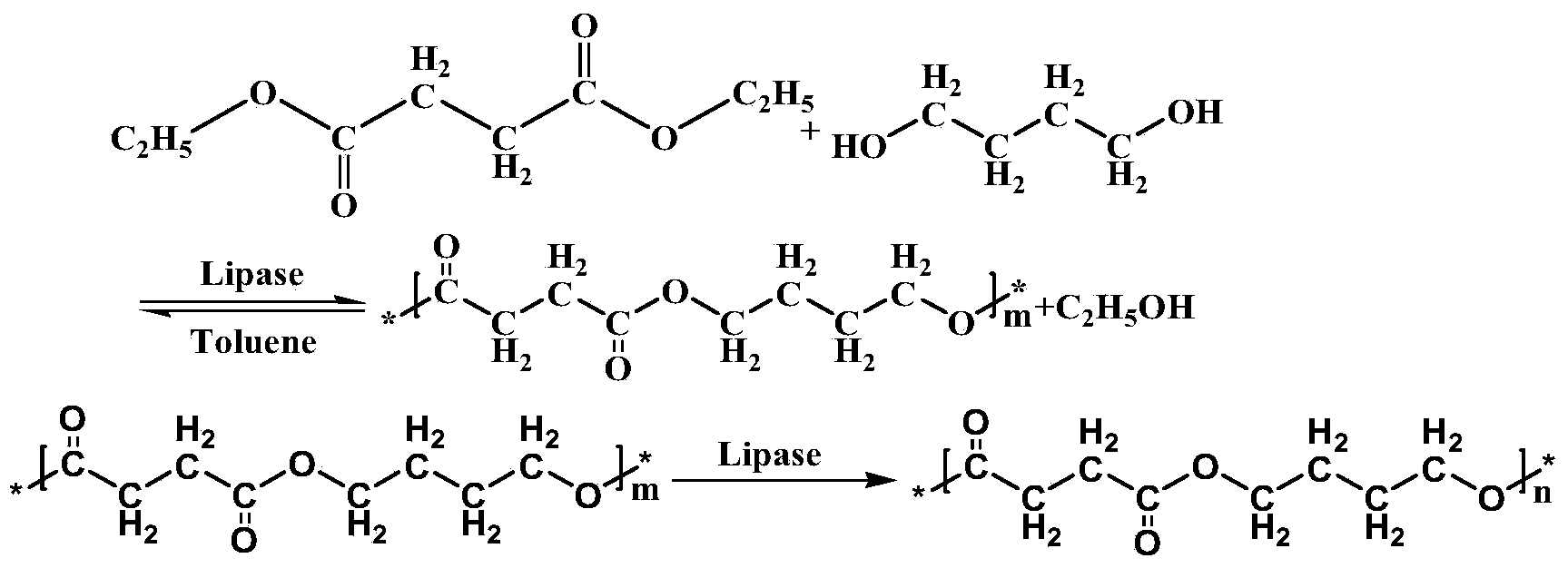

[0026] Embodiment 1, take diethyl succinate as acyl donor to prepare polybutylene succinate (reaction mode such as figure 1 shown)

[0027] (1) Add 30 parts of diethyl succinate, 35 parts of 1,4-butanediol and 100 parts of toluene respectively into the reaction flask, heat to 80°C and keep stirring, add 10 parts of lipase preparation Novozym43510, under normal pressure After 24 hours of solution polymerization, the enzyme preparation was removed by filtration (recyclable), and the filtrate was rotary evaporated at 35°C to remove the solvent (recyclable) to obtain a white prepolymer.

[0028] (2) Take 70 parts of the white prepolymer, add it to the reaction bottle, heat to 100°C and keep stirring, add lipase preparation Novozym 4355 parts after the prepolymer is melted, and stop the reaction after 40 hours of bulk polymerization under melting conditions; Add 100 parts of chloroform to dissolve the reaction mixture, filter and recover the enzyme preparation, slowly add the filt...

Embodiment 2

[0030] Embodiment 2, using dimethyl succinate as an acyl donor to prepare polybutylene succinate

[0031] (1) Add 35 parts of dimethyl succinate, 35 parts of 1,4-butanediol and 110 parts of toluene respectively into the reaction flask, heat to 80°C and keep stirring, add 12 parts of lipase preparation Novozym43512, under normal pressure After 24 hours of solution polymerization, the enzyme preparation was removed by filtration (recyclable), and the filtrate was rotary evaporated at 35°C to remove the solvent (recyclable) to obtain a white prepolymer.

[0032] (2) Take 70 parts of the white prepolymer, add it to the reaction bottle, heat to 100°C and keep stirring, add lipase preparation Novozym 4355 parts after the prepolymer is melted, and stop the reaction after 48 hours of bulk polymerization under melting conditions; Add 100 parts of chloroform to dissolve the reaction mixture, filter and recover the enzyme preparation, slowly add the filtrate dropwise to 500 parts of meth...

Embodiment 3

[0034] Embodiment 3, take succinic acid as acyl donor to prepare polybutylene succinate

[0035] (1) Add 30 parts of succinic acid, 36 parts of 1,4-butanediol and 200 parts of diphenyl ether into the reaction flask, heat to 65°C and keep stirring, add lipase preparation Novozym4355 parts, under normal pressure After solution polymerization for 24 hours, remove the enzyme preparation by filtration (recyclable), and spin the filtrate at 70°C to remove the solvent (recyclable), and obtain a white prepolymer;

[0036] (2) Take 70 parts of the white prepolymer, add it to the reaction bottle, heat to 85°C and keep stirring, add lipase preparation Novozym4355 parts after the prepolymer is melted, and stop the reaction after 48 hours of bulk polymerization under melting conditions; Add 100 parts of chloroform to dissolve the reaction mixture, filter and recover the enzyme preparation, slowly add the filtrate dropwise to 500 parts of methanol, filter the obtained white solid, and dry i...

PUM

| Property | Measurement | Unit |

|---|---|---|

| Melting point | aaaaa | aaaaa |

| Melting point | aaaaa | aaaaa |

| Weight average molecular weight | aaaaa | aaaaa |

Abstract

Description

Claims

Application Information

Login to View More

Login to View More - R&D

- Intellectual Property

- Life Sciences

- Materials

- Tech Scout

- Unparalleled Data Quality

- Higher Quality Content

- 60% Fewer Hallucinations

Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2025 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com