Preparation method of diethyl succinate

A technology of succinic acid diester and maleic anhydride, which is applied in the field of preparation of succinic acid diester, can solve the problems of low yield of methyl succinate, reduced activity of ion exchange resin solid acid catalyst, etc., and achieve The effect of reducing production cost, facilitating separation and refining, and simplifying the production process

- Summary

- Abstract

- Description

- Claims

- Application Information

AI Technical Summary

Problems solved by technology

Method used

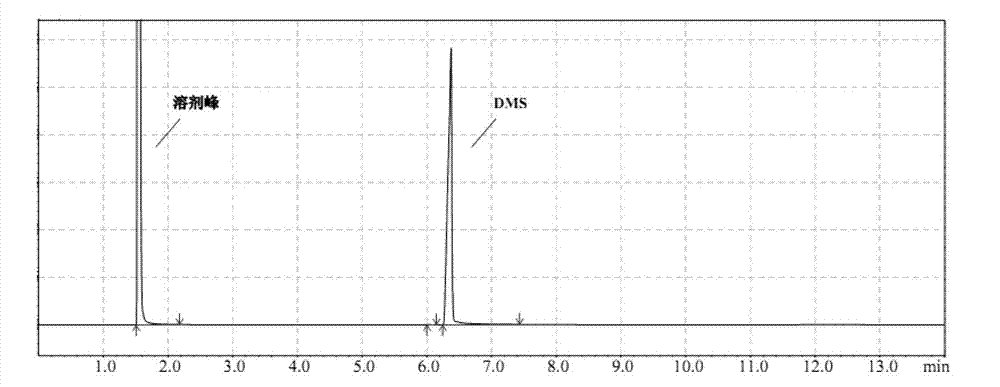

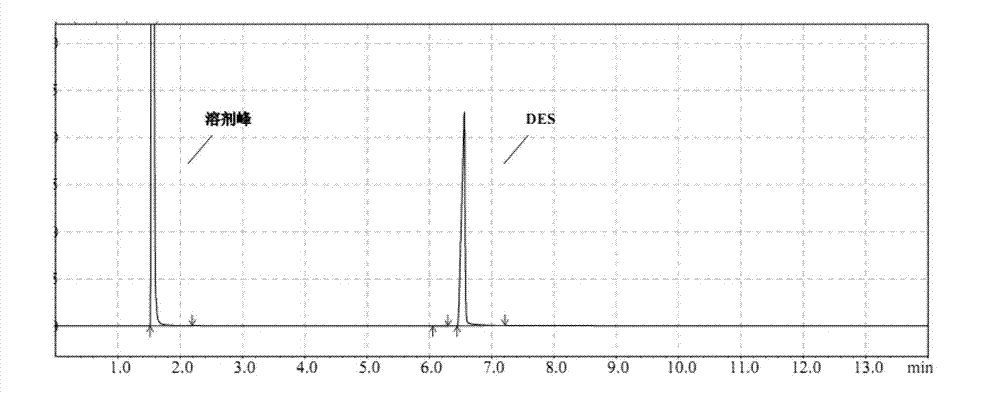

Image

Examples

preparation example Construction

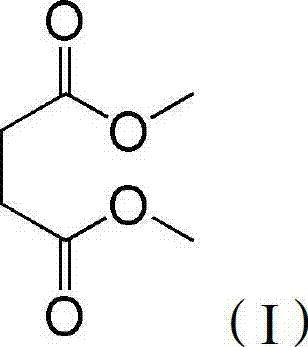

[0025] The invention provides a kind of preparation method of succinic acid diester, comprises the following steps:

[0026] Mix maleic anhydride, alcohol compounds, carbon dioxide, hydrogen and a hydrogenation catalyst to carry out esterification and hydrogenation reaction to obtain succinic acid diester.

[0027] The invention provides a method for preparing succinic acid diester. The method provided by the invention uses maleic anhydride, alcohol compounds and hydrogen as raw materials, carbon dioxide as a solvent and an acid catalyst, and carries out esterification under the catalysis of a hydrogenation catalyst. hydrogenation reaction to obtain succinic acid diester. The method provided by the invention uses carbon dioxide as a solvent and an acid catalyst for the esterification hydrogenation reaction, which has higher catalytic activity and improves the reaction rate; and it can also form an acid with the water generated in the reaction process, thereby promoting the rea...

Embodiment 1

[0048] Place 0.1 g of palladium chloride in 0.2 mL of dilute hydrochloric acid aqueous solution with a molar concentration of 1 mol / L, stir for 2 h to fully disperse the palladium chloride to obtain an aqueous palladium chloride solution; into the palladium chloride aqueous solution, fully immersed at room temperature, overnight, then dried at 60°C, and finally reduced at 150°C under a hydrogen atmosphere to obtain a supported Pd / C catalyst.

Embodiment 2

[0050] Put 0.28 g of nickel nitrate in 1 mL of water and stir for 1 h to obtain an aqueous solution of nickel nitrate; impregnate 1 g of the calcined pretreated aluminum oxide carrier into the aqueous solution of nitric acid, fully impregnate at room temperature overnight, and then Dry at 60°C, and finally calcined at 450°C in a muffle furnace, and then reduce under hydrogen atmosphere to obtain supported Ni / Al 2 o 3 catalyst.

PUM

| Property | Measurement | Unit |

|---|---|---|

| boiling point | aaaaa | aaaaa |

| melting point | aaaaa | aaaaa |

| flash point | aaaaa | aaaaa |

Abstract

Description

Claims

Application Information

Login to View More

Login to View More - R&D

- Intellectual Property

- Life Sciences

- Materials

- Tech Scout

- Unparalleled Data Quality

- Higher Quality Content

- 60% Fewer Hallucinations

Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2025 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com