Paraphase catalytic reaction-heterogeneous azeotropic distillation system and method

A catalytic reaction and azeotropic distillation technology, applied in the chemical industry, can solve the problems of large equipment investment, long product separation and refining process, and high energy consumption

- Summary

- Abstract

- Description

- Claims

- Application Information

AI Technical Summary

Problems solved by technology

Method used

Image

Examples

Embodiment 1

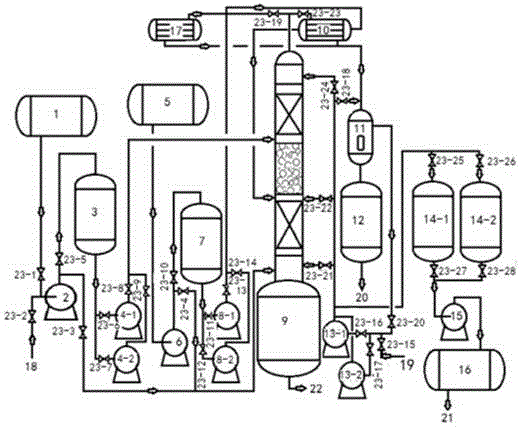

[0063] like figure 1 As shown, a dual-phase catalytic reaction-heterogeneous azeotropic distillation system includes: a first storage tank 1, a first feed pump 2, a first metering tank 3, a first metering pump 4-1, a second metering Pump 4-2, second storage tank 5, second feeding pump 6, second metering tank 7, third metering pump 8-1, fourth metering pump 8-2, rectification tower 9, first condenser 10, Stratifier 11, third metering tank 12, first reflux pump 13-1, second reflux pump 13-2, fourth metering tank 14-1, fifth metering tank 14-2, dump pump 15, intermediate tank 16 and the second condenser 17, wherein,

[0064] The rectification column 9 is composed of a column still and a column, and the first feed port, the second feed port and the third feed port are arranged in sequence from top to bottom on one side of the column, and the other side is arranged from top to bottom. The fourth feed port, the fifth feed port and the sixth feed port are provided in sequence, and ...

PUM

Login to View More

Login to View More Abstract

Description

Claims

Application Information

Login to View More

Login to View More - R&D

- Intellectual Property

- Life Sciences

- Materials

- Tech Scout

- Unparalleled Data Quality

- Higher Quality Content

- 60% Fewer Hallucinations

Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2025 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com