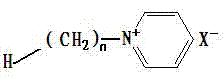

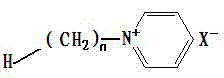

Method for preparing diethyl succinate catalyzed by pyridine ionic liquid

A technology of diethyl succinate and ionic liquids, applied in chemical instruments and methods, preparation of organic compounds, preparation of carboxylate, etc., can solve the problems of difficult recovery of catalysts, harsh reaction conditions, cumbersome post-treatment, etc., and achieve Effects that are easy to control, have short reaction times, and are inexpensive

- Summary

- Abstract

- Description

- Claims

- Application Information

AI Technical Summary

Problems solved by technology

Method used

Image

Examples

Embodiment 1

[0047] Example 1 The method for preparing pyridine diethyl succinate catalyzed by pyridine ionic liquid

[0048] Add 0.05mol succinic acid, 0.15mol ethanol, and 0.295g N-picoline hydrogen sulfate into a three-necked flask equipped with reflux condensation (the order of adding the three substances is not limited), magnetic stirring (stir while heating , the purpose is to make the reaction more uniform, increase the reaction rate and reduce the reaction time at the same time, the stirring method is not limited to magnetic stirring, other stirring methods can be used);

[0049] React at 60°C for 2h; then

[0050] Add the extractant diethyl ether, pour out the mixed solution in the upper layer, and remove the diethyl ether and excess ethanol by rotary evaporation under reduced pressure at 40-55°C to obtain the crude product of diethyl succinate;

[0051] Cool and crystallize at 0°C for 1 hour, and centrifuge to remove the crystallized solid succinic acid to obtain pure diethyl s...

Embodiment 2

[0053] Example 2 The method for preparing diethyl succinate catalyzed by pyridine ionic liquid

[0054] Add 0.05mol of succinic acid, 0.15mol of ethanol, and 0.31g of N-ethylpyridine bisulfate into a three-necked flask equipped with reflux condensation, and stir magnetically.

[0055] React at 65°C for 2h; then

[0056] Add the extractant diethyl ether, pour out the mixed solution in the upper layer, and remove the diethyl ether and excess ethanol by rotary evaporation under reduced pressure at 40-55°C to obtain the crude diethyl succinate;

[0057] Cool and crystallize at 5°C for 1.5h, and centrifuge to remove the crystallized solid succinic acid to obtain a pure product. The esterification rate is 94.32%, and the selectivity is 100%.

[0058] The ionic liquid in the lower layer of the extract can be used again as a catalyst in the next cycle after simple rotary evaporation treatment, thus being reused.

Embodiment 3

[0059] Example 3 The method for preparing diethyl succinate catalyzed by pyridine ionic liquid

[0060] Add 0.05mol succinic acid, 0.15mol ethanol, and 0.325g N-propylpyridine tetrafluoroborate into a three-necked flask equipped with reflux condensation, and stir magnetically.

[0061] React at 60°C for 2.5h; then

[0062] Add the extractant diethyl ether, pour out the mixed solution in the upper layer, and remove the diethyl ether and excess ethanol by rotary evaporation under reduced pressure at 40-55°C to obtain the crude product diethyl succinate;

[0063] Cool and crystallize at 10°C for 4 hours, and remove the crystallized solid succinic acid to obtain a pure product. The esterification rate is 93.16%, and the selectivity is 100%.

[0064] The ionic liquid in the lower layer of the extract can be used again as a catalyst in the next cycle after simple rotary evaporation treatment, thus being reused.

PUM

| Property | Measurement | Unit |

|---|---|---|

| esterification rate | aaaaa | aaaaa |

| esterification rate | aaaaa | aaaaa |

| esterification rate | aaaaa | aaaaa |

Abstract

Description

Claims

Application Information

Login to View More

Login to View More - R&D

- Intellectual Property

- Life Sciences

- Materials

- Tech Scout

- Unparalleled Data Quality

- Higher Quality Content

- 60% Fewer Hallucinations

Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2025 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com