Method for preparing gamma-butyrolactone through catalytic hydrogenation of dimethyl succinate

A dimethyl succinate, catalytic hydrogenation technology, applied in the chemical industry, can solve environmental pollution and other problems, achieve the effect of shortening the operation time, increasing the pH value, and continuous process

- Summary

- Abstract

- Description

- Claims

- Application Information

AI Technical Summary

Problems solved by technology

Method used

Image

Examples

Embodiment 1

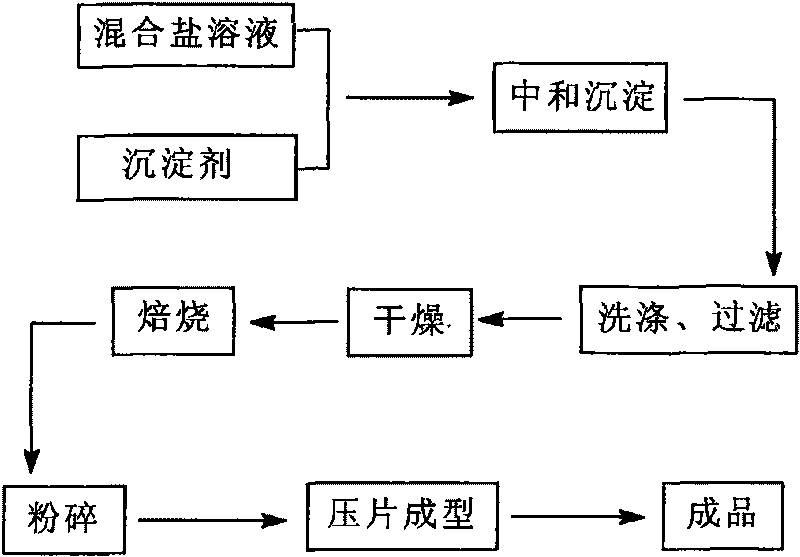

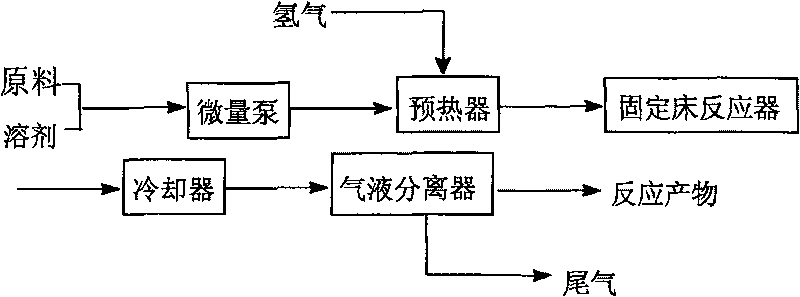

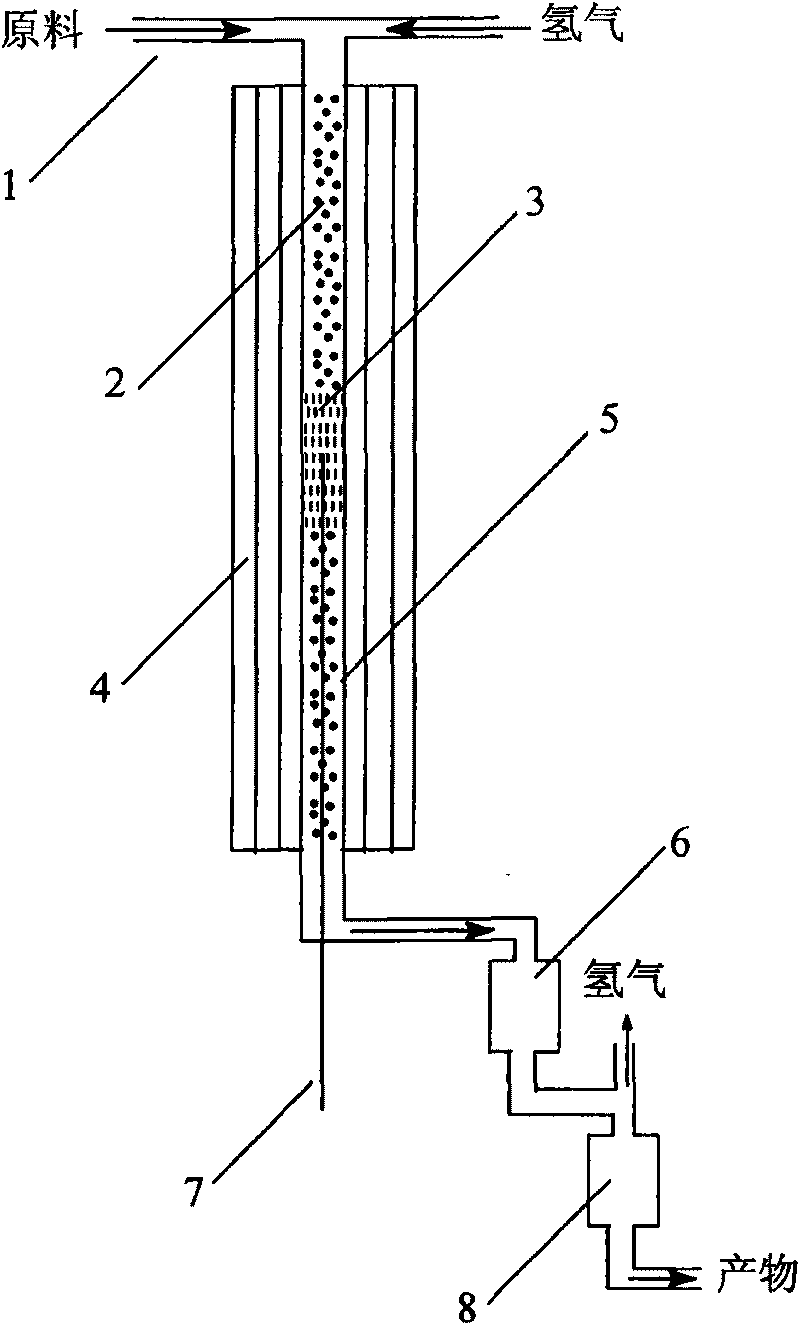

[0027] 1. Preparation and pretreatment of catalyst: 249.7g CuSO 4 ·5H 2 O, 16.8g ZnCl 2 And 73.6g Al(NO 3 ) 3 ·9H 2 O is dissolved in deionized water to form a 1mol / L solution. Then, under the condition of high-speed stirring and constant temperature water bath at 60℃, 2mol / L NaOH solution was added dropwise to a small amount of deionized water at the same time to generate precipitation. During the precipitation process, pH 7-8 was controlled. After the precipitation was complete, stirring was continued for 1h, and then at 80℃ Leave it to stand and age in a constant temperature water bath for 1 hour, overnight. The precipitate was filtered, washed, dried at 100°C for 24h, calcined at 300°C for 12h, and finally pressed into a tablet with a compressive strength of 5MPa. Take the 10 mesh catalyst precursor into a fixed-bed tubular reactor with an inner diameter of 8mm and a length of 800mm, with a packing rate of 3%, adjust the temperature to 150°C and pressure to 0.5MPa, and then...

Embodiment 2

[0031] 1. Preparation and pretreatment of the catalyst: 170.5g CuCl 2 ·2H 2 O, 94.7g ZnSO 4 ·7H 2 O and 11.0g Ba(NO 3 ) 2 Dissolve in deionized water to form a 1mol / L solution. Then, mix with 1mol / L of K under high-speed stirring 2 CO 3 The solution was added dropwise to 64.5g 31%(Wt, SiO 2 ) Precipitation is formed in the silica sol solution. The following steps are the same as in Example 1. Drying at 110°C for 16 hours and baking at 350°C for 10 hours. Take a 20-mesh catalyst precursor fixed-bed reactor with a pressure resistance of 10MPa, the filling rate is 5%, the temperature is adjusted to 200℃ and the pressure is 1.0MPa, and then hydrogen and nitrogen with a volume of 15% of hydrogen are introduced into the reactor. The activation time is 8h.

[0032] 2. Catalytic hydrogenation: The temperature of the reactor is raised to 350°C, the pressure is 2.0MPa, and the mixed solution of dimethyl succinate and methanol in a volume ratio of 1:3 is pumped into the fixed bed reactor t...

Embodiment 3

[0035] 1. The preparation and pretreatment of the catalyst: 241.6g Cu(NO 3 ) 2 ·3H 2 O, 146.9g Zn(NO 3 ) 2 ·6H 2 O, 13.2gBa(NO 3 ) 2 , 33.7g Ca(NO 3 ) 2 ·4H 2 O and 75.0g Al(NO 3 ) 3 ·9H 2 O is dissolved in deionized water to form a 1mol / L solution. Then, mix with 1mol / L Na 2 CO 3 The solution solution was added dropwise to 44.5g 31%(Wt, SiO 2 ) Precipitation is formed in the silica sol solution. The following steps are the same as in Example 1. Drying at 120°C for 12 hours and firing at 400°C for 8 hours. Take a 30-mesh catalyst precursor fixed-bed reactor with a pressure resistance of 20MPa, the filling rate is 10%, the temperature is adjusted to 250°C and the pressure is 2.0MPa, and then hydrogen and nitrogen with 30% of the hydrogen volume are introduced into the reactor. The activation time is 6h.

[0036] 2. Catalytic hydrogenation: The temperature of the reactor is raised to 300°C, the pressure is 3.00MPa, and the mixed solution of dimethyl succinate and methanol in a vol...

PUM

| Property | Measurement | Unit |

|---|---|---|

| compressive strength | aaaaa | aaaaa |

Abstract

Description

Claims

Application Information

Login to View More

Login to View More - R&D

- Intellectual Property

- Life Sciences

- Materials

- Tech Scout

- Unparalleled Data Quality

- Higher Quality Content

- 60% Fewer Hallucinations

Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2025 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com