Mixed solvent used for dissolving nitrated cellulose and nitrated cellulose product containing mixed solvent

A technology of nitrocellulose and mixed solvents, which is applied in the fields of fiber treatment, textiles and papermaking, etc. It can solve the problems of long residence time on the leather surface, harm to the environment by operators, and strong odor of solvents, etc., achieve good dissolution effect, improve physical properties, The effect of high emulsion stability

- Summary

- Abstract

- Description

- Claims

- Application Information

AI Technical Summary

Problems solved by technology

Method used

Image

Examples

Embodiment 1

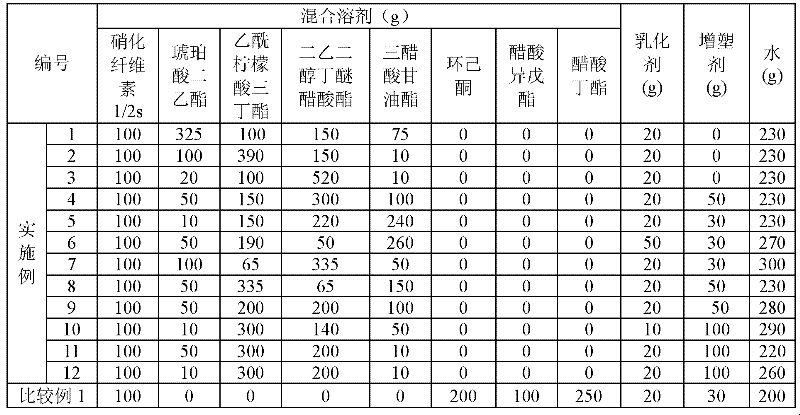

[0046] The diethyl succinate of 100g, the acetyl tributyl citrate of 100g, the diethylene glycol butyl ether acetate of 300g and the glyceryl triacetate of 150g are placed in a 1L round-bottomed flask, and they are mixed uniformly to obtain Mixed solvents for preparing water-soluble nitrocellulose products. Then add 100 g of nitrocellulose (NC1 / 2ww, Luzhou North Nitrocellulose Co., Ltd., 1 / 2 second water-based nitrocellulose) to the resulting mixed solvent and stir until completely dissolved. Since the raw materials required for the preparation of the product are all inflammable and explosive products, the temperature should be kept as low as possible during the preparation process. No heating is required during stirring, and the ambient temperature during stirring should not exceed 30°C. Next, 20 g of emulsifier Meltiso 13120 (manufactured by Nanjing SASOL Co., Ltd.) and 230 g of water were added to the obtained mixed solution, and stirred for 1.5 hours to form a stable emul...

Embodiment 2-3

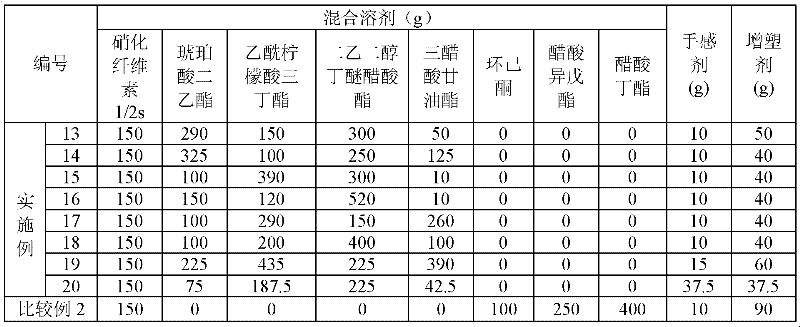

[0051] Except that the amount of diethyl succinate, acetyl tributyl citrate, diethylene glycol butyl ether acetate and glycerol triacetate is different and the time of stirring is different, prepare Example 2 with the same method as Example 1 -3 water-soluble nitrocellulose products.

Embodiment 4

[0053]50 g of diethyl succinate, 150 g of acetyl tributyl citrate, 300 g of diethylene glycol butyl ether acetate, 100 g of triacetin, and 20 g of propylene glycol adipate as a plasticizer and 30g of diethyl adipate were placed in a 1L round bottom flask, and mixed evenly to obtain a mixed solvent for preparing water-soluble nitrocellulose products. Then add 100 g of nitrocellulose (NC1 / 2ww, Luzhou North Nitrocellulose Co., Ltd., 1 / 2 second water-based nitrocellulose) to the resulting mixed solvent and stir until completely dissolved. To the resulting mixed solution, 20 g of Meltiso 13120 (Nanjing SASOL) was added as an emulsifier, and then 230 g of water was added and stirred for 2 hours to form a stable emulsion. When in use, mix the above-obtained emulsion with tap water 1:1 (v / v), stir evenly, and spray the leather with a NEW-71 type spray gun (manufactured by ANEST IWATA Company) in a spray booth (GEMATA ITALY) , The spraying amount is 2-4 g / ft. Then put the sprayed lea...

PUM

Login to View More

Login to View More Abstract

Description

Claims

Application Information

Login to View More

Login to View More - R&D

- Intellectual Property

- Life Sciences

- Materials

- Tech Scout

- Unparalleled Data Quality

- Higher Quality Content

- 60% Fewer Hallucinations

Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2025 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com