Structural adhesive for building of bridge with precast segmental matching method

A matching method and structural adhesive technology, applied in the direction of adhesives, epoxy resin adhesives, adhesive types, etc., can solve the problems of operating time, early strength and color stability that cannot meet the process requirements at the same time, achieve color stability, early High strength, low heat release effect

- Summary

- Abstract

- Description

- Claims

- Application Information

AI Technical Summary

Problems solved by technology

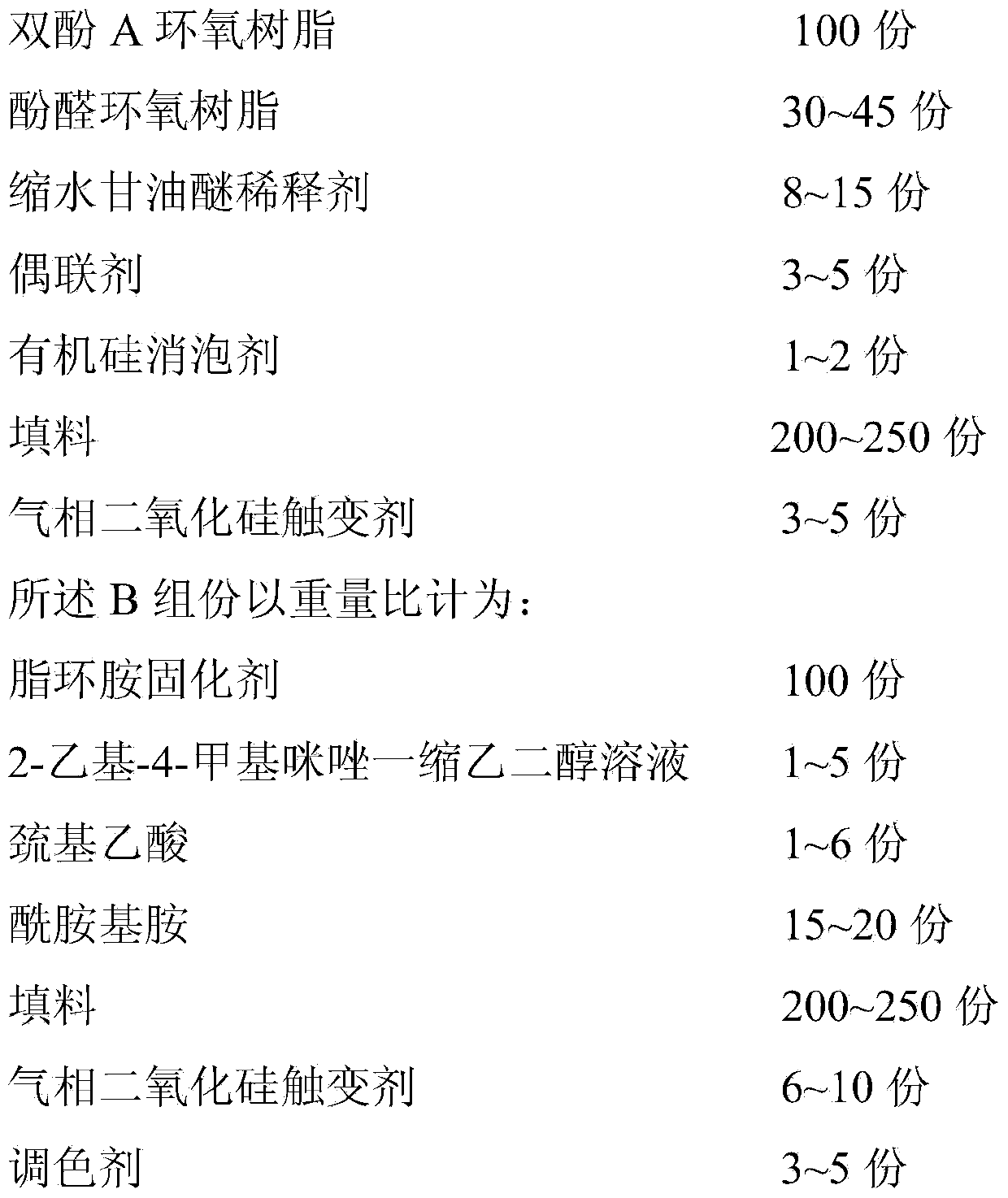

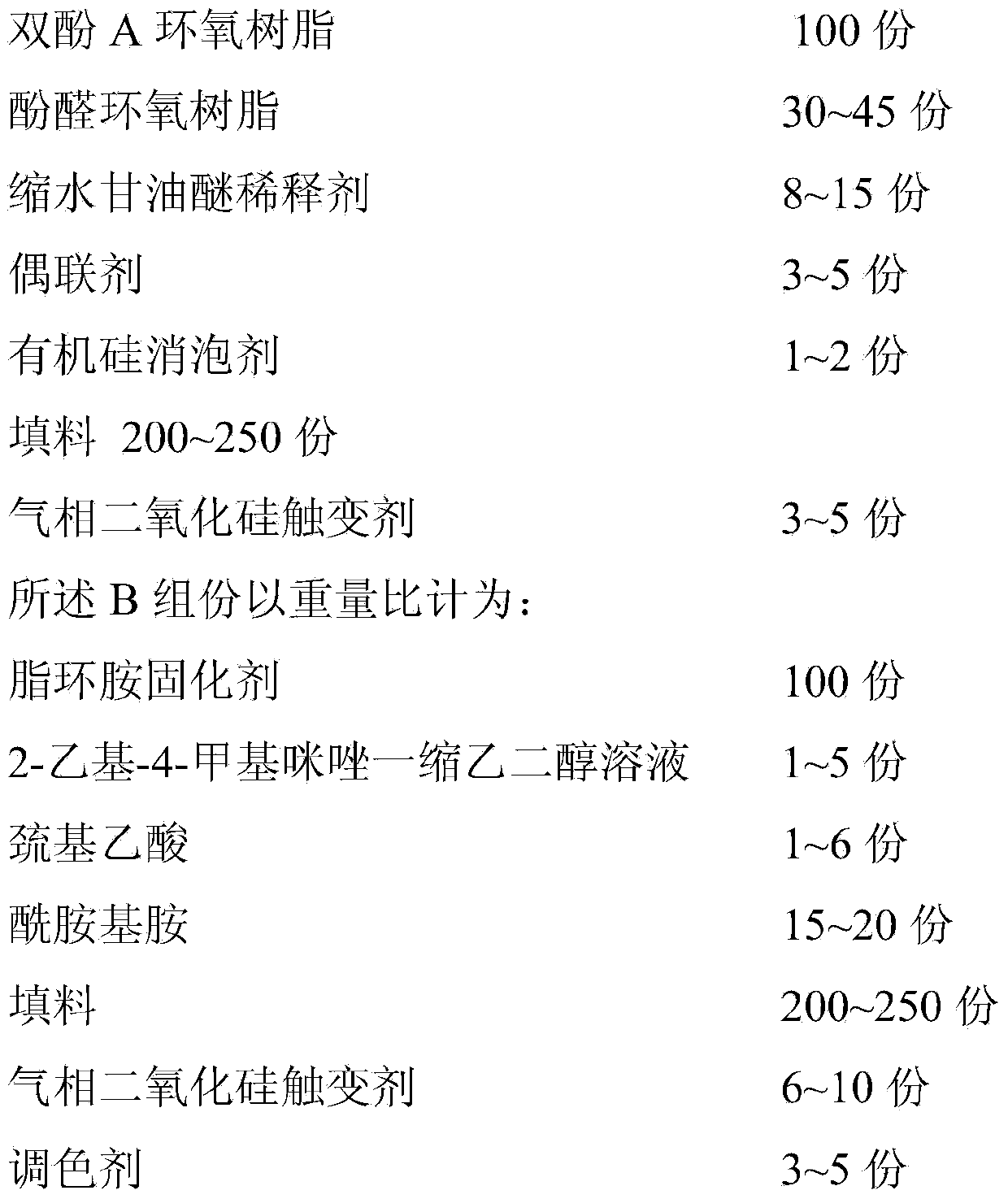

Method used

Image

Examples

Embodiment 1

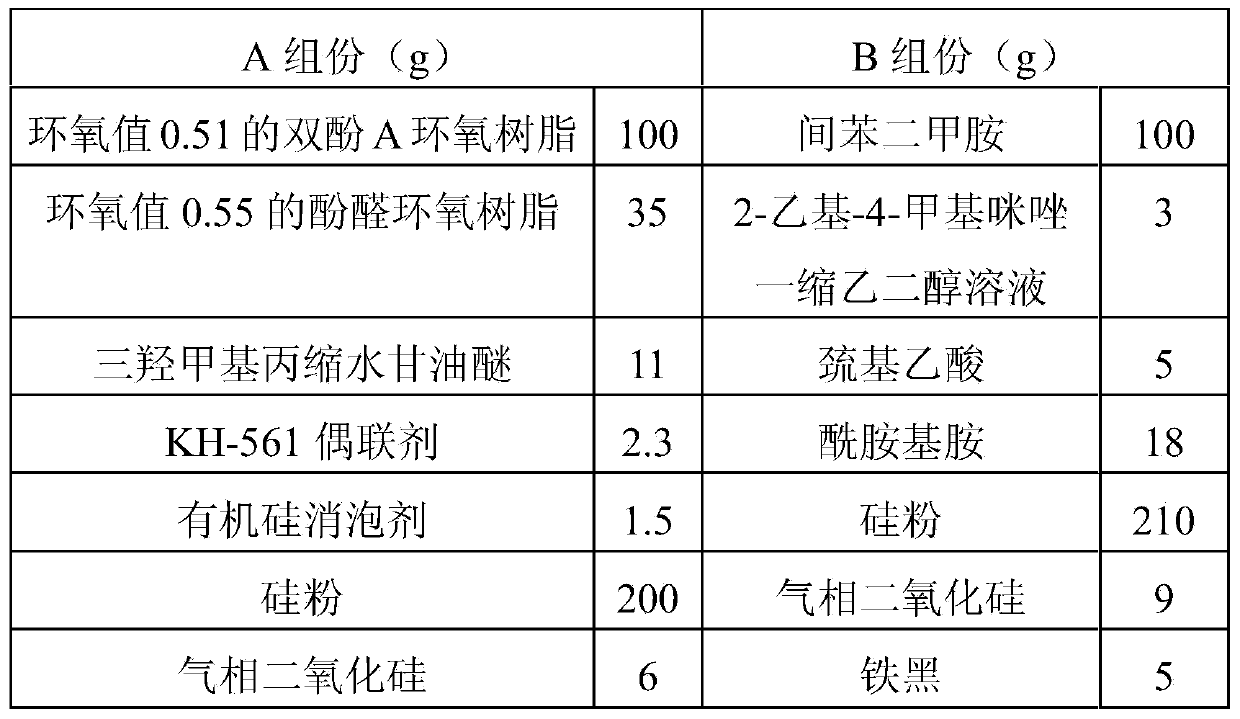

[0026] Table 1 shows the preparation ratio of structural glue used in the construction of the bridge by the prefabricated segment matching method in this embodiment:

[0027]

[0028] Table 1

[0029] Wherein, the mass percentage concentration of the 2-ethyl-4-methylimidazole-ethylene glycol solution that adopts is 60%, and the thioglycolic acid is selected from the technical grade thioglycolic acid that the purity is more than 98%, and the preparation method is as follows:

[0030] (1) Mix 100g of bisphenol A epoxy resin with an epoxy value of 0.51, 35g of novolak epoxy resin with an epoxy value of 0.55, 11g of trimethylol propylene glycidyl ether, 1.5g of silicone defoamer, 2.3g of KH-561 Add coupling agent and 6g fumed silica into the reaction kettle and stir evenly, then add 200g silicon powder, stir evenly to obtain component A;

[0031] (2) Add 100g of m-xylylenediamine, 18g of amidoamine, 3g of 2-ethyl-4-methylimidazole-ethylene glycol solution, 5g of mercaptoacetic...

Embodiment 2

[0034] Table 2 shows the proportion of structural adhesives used in the construction of bridges by the prefabricated segment matching method in this embodiment:

[0035]

[0036] Table 2

[0037] Wherein, the mass percentage concentration of the 2-ethyl-4-methylimidazole-ethylene glycol solution that adopts is 60%, and the thioglycolic acid is selected from the technical grade thioglycolic acid that the purity is more than 98%, and the preparation method is as follows:

[0038] (1) Mix 100g of bisphenol A epoxy resin with an epoxy value of 0.48, 45g of novolac epoxy resin with an epoxy value of 0.58, 10g of ethylene glycol diglycidyl ether, 1g of silicone defoamer, and 2g of KH-570 coupling agent Add 5g of fumed silica into the reaction kettle and stir evenly, then add 245g of barite powder, stir evenly to obtain component A;

[0039] (2) Add 100g of isophorone diamine, 20g of amidoamine, 2g of 2-ethyl-4-methylimidazole-ethylene glycol solution, 4g of mercaptoacetic acid, ...

Embodiment 3

[0042] Table 3 shows the proportion of structural adhesives used in the construction of bridges by the prefabricated segment matching method in this embodiment:

[0043]

[0044] table 3

[0045] Wherein, the mass percentage concentration of the 2-ethyl-4-methylimidazole-ethylene glycol solution that adopts is 60%, and the thioglycolic acid is selected from the technical grade thioglycolic acid that the purity is more than 98%, and the preparation method is as follows:

[0046] (1) Mix 100g of bisphenol A epoxy resin with an epoxy value of 0.51, 38g of novolac epoxy resin with an epoxy value of 0.60, 9g of polypropylene glycol diglycidyl ether, 2g of silicone defoamer, 3g of KH-560 coupling agent and Add 5g of fumed silica into the reaction kettle and stir evenly, then add 245g of silicon powder, stir evenly to obtain component A;

[0047] (2) Add 100g of cyclohexanedimethylamine, 15g of amidoamine, 4g of 2-ethyl-4-methylimidazole-ethylene glycol solution, 3g of mercaptoac...

PUM

| Property | Measurement | Unit |

|---|---|---|

| compressive strength | aaaaa | aaaaa |

| compressive strength | aaaaa | aaaaa |

| epoxy value | aaaaa | aaaaa |

Abstract

Description

Claims

Application Information

Login to View More

Login to View More - R&D

- Intellectual Property

- Life Sciences

- Materials

- Tech Scout

- Unparalleled Data Quality

- Higher Quality Content

- 60% Fewer Hallucinations

Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2025 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com