Flexible-packaged high-power lithium iron phosphate power battery

A lithium iron phosphate and power battery technology, applied in the field of lithium-ion power batteries, can solve the problems of large heat generation and poor high-rate discharge performance, and achieve the effects of reducing heat release, improving electrical conductivity, and improving high-rate cycle performance.

- Summary

- Abstract

- Description

- Claims

- Application Information

AI Technical Summary

Problems solved by technology

Method used

Image

Examples

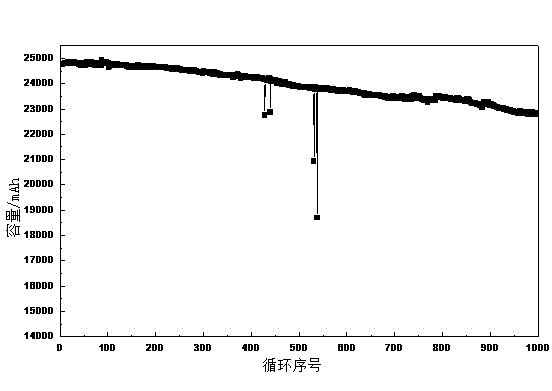

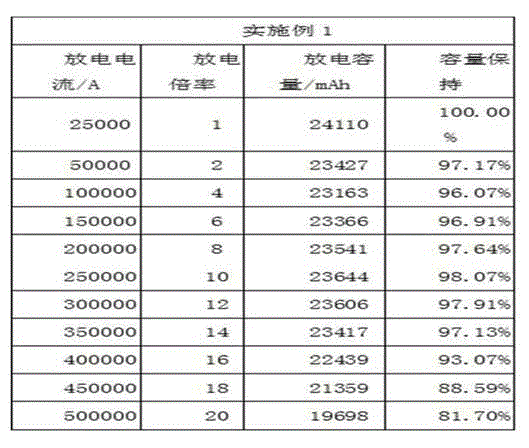

Embodiment 1

[0019] Preparation of the positive electrode sheet: Lithium iron phosphate particles with a particle size of 40-200 nm coated with graphene with a coating thickness of less than 3.5 nm are used as the positive electrode active material. Lithium iron phosphate, polyvinylidene fluoride, conductive carbon black, scaly graphite, and carbon nanotubes were prepared in a ratio of 90:5:3:1.5:0.5 to prepare positive electrode slurry, and coated on a positive electrode sheet assembly with a thickness of 19 microns Fluid-on, where the conductive coating (both sides) is 3 µm thick. The prepared area density is 220g / m 2 the positive plate.

[0020] Preparation of negative electrode sheet: Negative electrode slurry was prepared by preparing negative electrode active material 92%, sodium carboxymethyl cellulose, styrene-butadiene rubber, and conductive carbon black at a ratio of 91:2.5:1.5:4. The ratio of mesocarbon microspheres, artificial graphite, and hard carbon in the positive active ...

Embodiment 2

[0027] Preparation of the positive electrode sheet: Lithium iron phosphate particles with a particle size of 40-200 nm coated with graphene with a coating thickness of less than 3.5 nm are used as the positive electrode active material. Lithium iron phosphate, polyvinylidene fluoride, conductive carbon black, and scaly graphite were used to prepare positive electrode slurry according to the ratio of 91:5:2.5:1.5, and coated on the positive electrode current collector with a thickness of 19 microns, in which the conductive coating (Double sided) 3 microns thick. The prepared areal density is 250g / m 2 the positive plate.

[0028] Preparation of negative electrode sheet: Negative electrode slurry was prepared by preparing 92% negative electrode active material, sodium carboxymethyl cellulose, styrene-butadiene rubber, and conductive carbon black at a ratio of 92:2.5:1.5:3. The ratio of mesocarbon microspheres, artificial graphite, and hard carbon in the positive active material...

PUM

| Property | Measurement | Unit |

|---|---|---|

| particle diameter | aaaaa | aaaaa |

| thickness | aaaaa | aaaaa |

| thickness | aaaaa | aaaaa |

Abstract

Description

Claims

Application Information

Login to View More

Login to View More - R&D

- Intellectual Property

- Life Sciences

- Materials

- Tech Scout

- Unparalleled Data Quality

- Higher Quality Content

- 60% Fewer Hallucinations

Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2025 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com