Lithium battery and forming method therefor

A lithium battery and lithium transition metal technology, applied in secondary batteries, battery electrodes, non-aqueous electrolyte storage batteries, etc., can solve problems such as inability to effectively suppress deoxidation, battery explosion, and no thermal actuation safety mechanism, etc., to achieve discharge Effects of less heat, improved safety, and improved capacitance

- Summary

- Abstract

- Description

- Claims

- Application Information

AI Technical Summary

Problems solved by technology

Method used

Image

Examples

Embodiment 1

[0048] Soak the positive plate of Comparative Example 2 into a 10mM Prussian blue aqueous solution, and stir and mix at room temperature for about 3 days to allow the Prussian blue to modify LiNi through the holes of the positive plate. 4 co 2 mn 4 o 2 powder surface.

[0049] As for the negative electrode plate, the separator, the composition of the electrolyte, and the size of the battery formed by packaging, they are all the same as those of Comparative Example 1. In other words, the difference between Example 1 and Comparative Example 1 is that LiNi 4 co 2 mn 4 o 2 The surface of the powder is modified with nitrogen-containing polymer and Prussian blue.

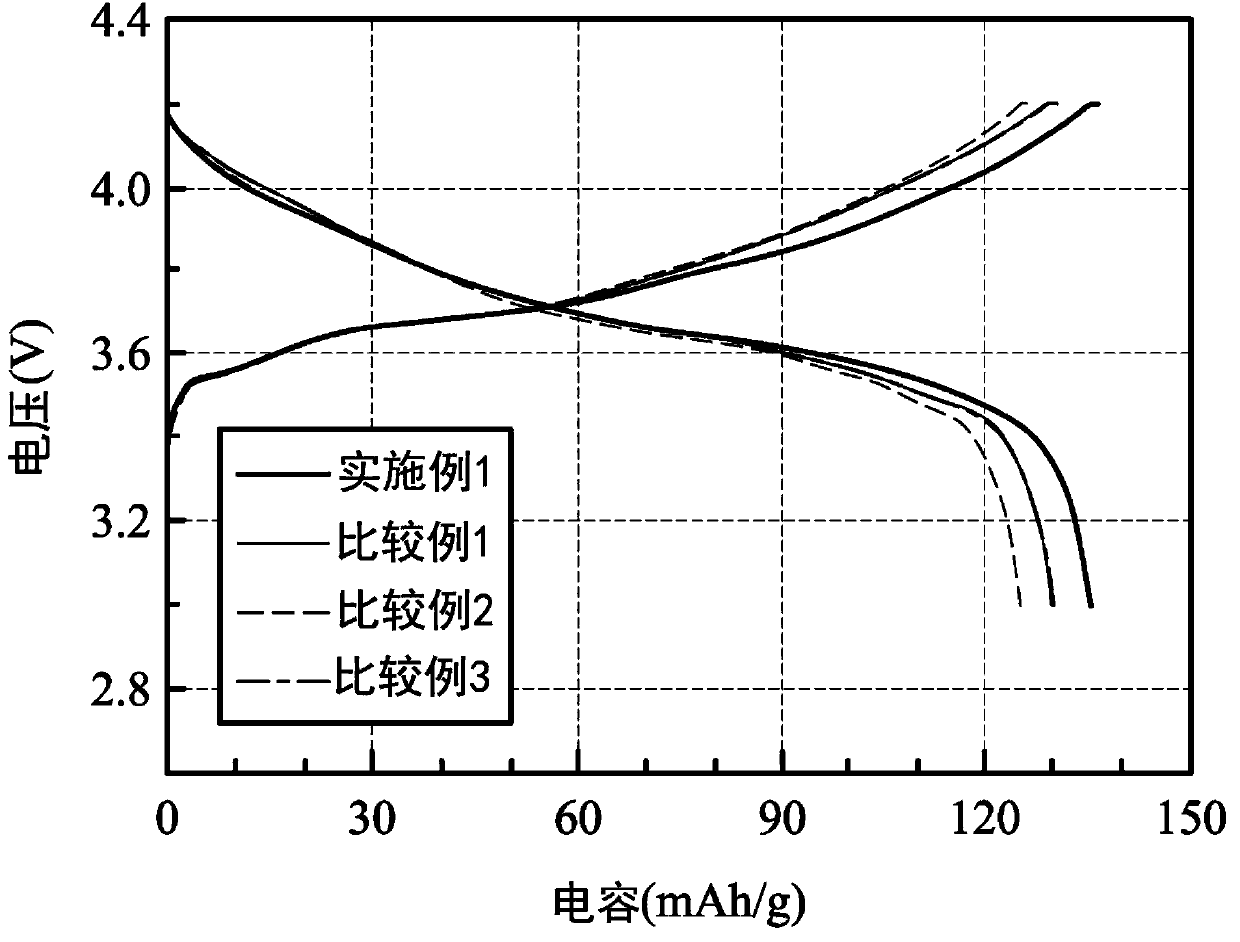

[0050] The charge-discharge curve of the lithium battery of embodiment 1 at the charge-discharge voltage of 4.3V to 3.0V and the charge-discharge current density of 0.1C / 0.1C is as follows Figure 2A As shown, the charge-discharge curve of the charge-discharge voltage from 4.3V to 3.0V and the charge-discharge cur...

PUM

| Property | Measurement | Unit |

|---|---|---|

| particle diameter | aaaaa | aaaaa |

| particle diameter | aaaaa | aaaaa |

| particle diameter | aaaaa | aaaaa |

Abstract

Description

Claims

Application Information

Login to View More

Login to View More - R&D

- Intellectual Property

- Life Sciences

- Materials

- Tech Scout

- Unparalleled Data Quality

- Higher Quality Content

- 60% Fewer Hallucinations

Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2025 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com