Hybrid polymers made of cyanates and silazanes, method for the production and use thereof

A cyanate ester and silazane technology, applied in the field of hybrid prepolymers and hybrid polymers, can solve problems such as lack of fire resistance, achieve low hardening temperature, improve flame retardancy, and high inherent flame retardancy Effect

- Summary

- Abstract

- Description

- Claims

- Application Information

AI Technical Summary

Problems solved by technology

Method used

Image

Examples

Embodiment 1-

[0118] Example 1 - Preparation of polymer from 4,4'-methylmethylene-diphenyl dicyanate (L10) and hexamethylcyclotrisilazane (HMCTS)

[0119] 4,4'-Methylmethylene-diphenyl dicyanate (L10) was mixed with Hexamethylcyclotrisilazane (HMCTS) mixed.

[0120] This mixture was poured into a flat casting mold and heated to 70°C. After about 2 hours, the temperature was increased to 200° C., and after a further 2 hours to 250° C., and kept at this temperature for 1 hour to post-harden the prepolymer formed. After a total of 6.5 hours, the temperature was slowly lowered to room temperature. A slightly yellowish-brown translucent plate with a dry surface was obtained.

Embodiment 2-

[0121] Example 2 - Preparation of polymer from 4,4'-methylmethylene-diphenyl dicyanate (L10) and trimethyltrivinylcyclotrisilazane (TMTVCTS)

[0122] The dicyanate is mixed with the silazane in an equivalent ratio of about 7:3 to about 9:1 at room temperature (at which temperature it is liquid) without solvent.

[0123] At an equivalence ratio of 7:3, heat to 70° C. and keep at this temperature for about 2 hours. It was then heated to 200° C. and kept at this temperature for 1 hour. After a total of 6.5 hours, the temperature was slowly lowered to room temperature. A slightly yellowish-brown translucent plate is obtained. Its glass transition temperature is about 80°C.

[0124] In another hardening embodiment, the mixture (equivalent ratio 7:3 to 9:1) is likewise poured into a flat casting mold and heated to 70°C. After about 2 hours, the temperature was increased to 200° C., and after a further 2 hours to 250° C., and kept at this temperature for 1 hour to post-harden the...

Embodiment 3a and 3b

[0140] 4,4′-Methylmethylene-diphenyl dicyanate (L10) was mixed with vinyl in an equivalent ratio of 8:2 at room temperature (at which it was liquid) without solvent - Methyl-polysilazane (VL100) (Example 3a) or a cyclic silazane (VML50) obtained from 50 mol % of dichlorovinylmethylsilane and 50 mol % of dichlorodimethylsilane (Example 3a) 3b) Mixing. These mixtures were all fed into the mold here and hardened according to embodiment 1 of example 2 (equivalent ratio 1:1) at a maximum hardening temperature of 200° C. The glass transition temperature T of the final hardened polymer from Example 3b was measured g It is 185°C; Example 3a is slightly higher.

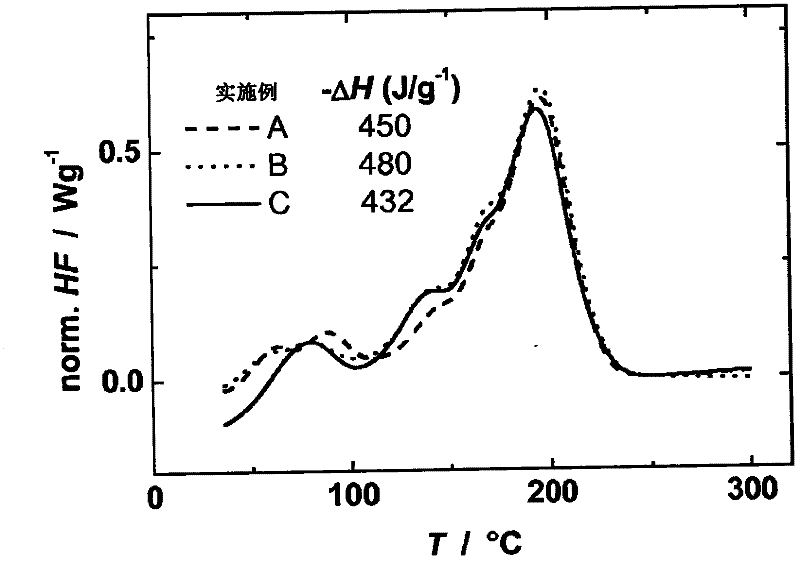

[0141] figure 1 Shown are the exotherms of the reactions according to examples 3a (curve A) and 3b (curve 3b). -ΔH(J / g -1 ) has a numerical value of 450 or 480.

PUM

| Property | Measurement | Unit |

|---|---|---|

| glass transition temperature | aaaaa | aaaaa |

| glass transition temperature | aaaaa | aaaaa |

| glass transition temperature | aaaaa | aaaaa |

Abstract

Description

Claims

Application Information

Login to View More

Login to View More - R&D

- Intellectual Property

- Life Sciences

- Materials

- Tech Scout

- Unparalleled Data Quality

- Higher Quality Content

- 60% Fewer Hallucinations

Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2025 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com