A method for preparing multifunctional nano-protective coating by alternating cycle discharge

A multi-functional, cycle-period technology, applied in the direction of coating, metal material coating process, gaseous chemical plating, etc., can solve the protective properties such as high degree of powderization, coating waterproof, moisture-proof, corrosion resistance, solvent resistance, etc. Poor, loose coating structure and other problems, to achieve the effect of dense film structure, good protection effect and high coating efficiency

- Summary

- Abstract

- Description

- Claims

- Application Information

AI Technical Summary

Problems solved by technology

Method used

Image

Examples

Embodiment 1

[0068] A method for preparing a multifunctional nano-protective coating with alternate discharge cycles, comprising the following steps:

[0069] (1) The base material is placed in the reaction chamber of the nano-coating preparation equipment, the reaction chamber is closed and the reaction chamber is continuously evacuated, the vacuum degree in the reaction chamber is evacuated to 10 millitorr, and the inert gas Ar is passed into, Turn on the motion mechanism to make the substrate move in the reaction chamber;

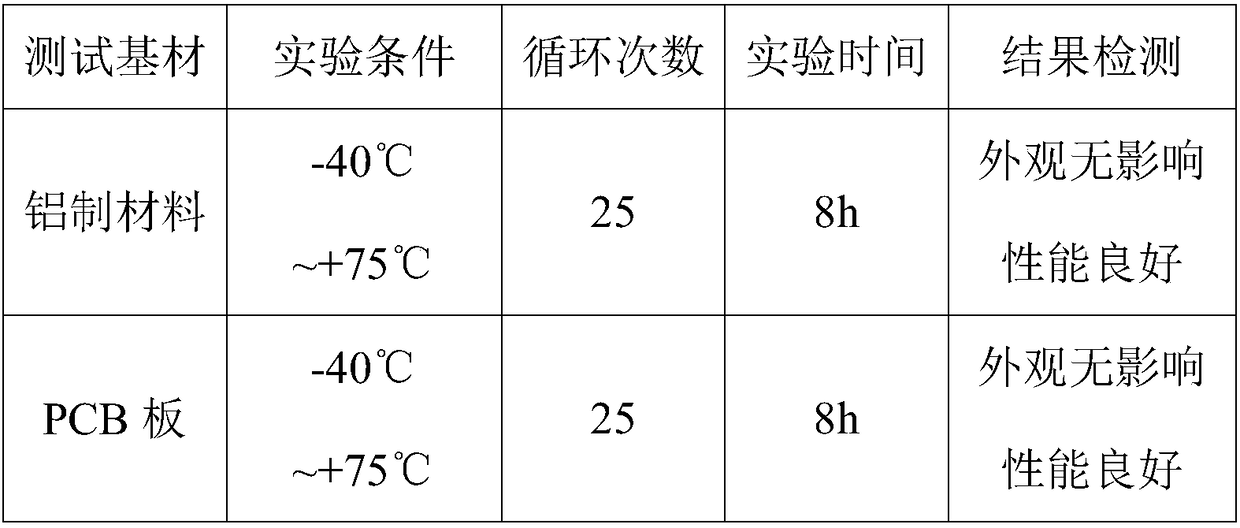

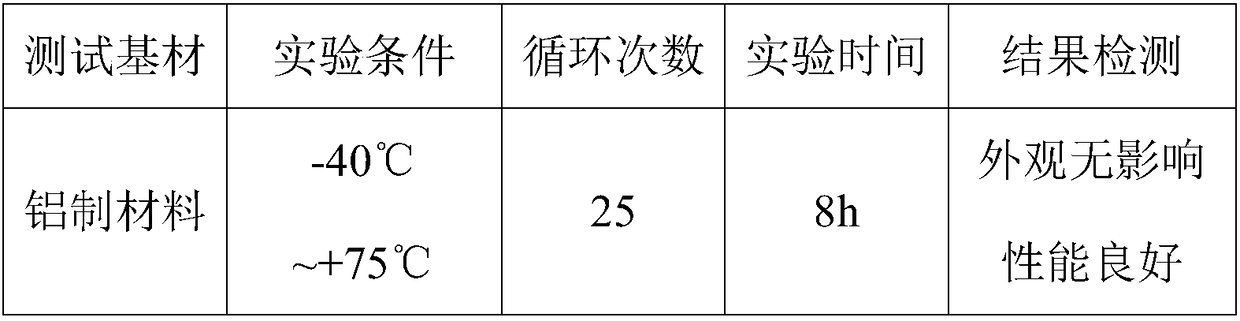

[0070] In step (1), the base material is a solid material, and the solid material is a block aluminum material and a PCB board, and any interface of the base material surface can be exposed to cold and heat after the cold and heat cycle impact coating is prepared. in a loop test environment.

[0071] In step (1), the volume of the reaction chamber is 50 L, the temperature of the reaction chamber is controlled at 30° C., and the flow rate of the inert gas is 5 sccm. ...

Embodiment 2

[0090] A method for preparing a multifunctional nano-protective coating with alternate discharge cycles, comprising the following steps:

[0091] (1) Place the substrate in the reaction chamber of the nano-coating preparation equipment, close the reaction chamber and continuously evacuate the reaction chamber, pump the vacuum in the reaction chamber to 60 millitorr, feed inert gas He, and start Motion mechanism to make the base material move;

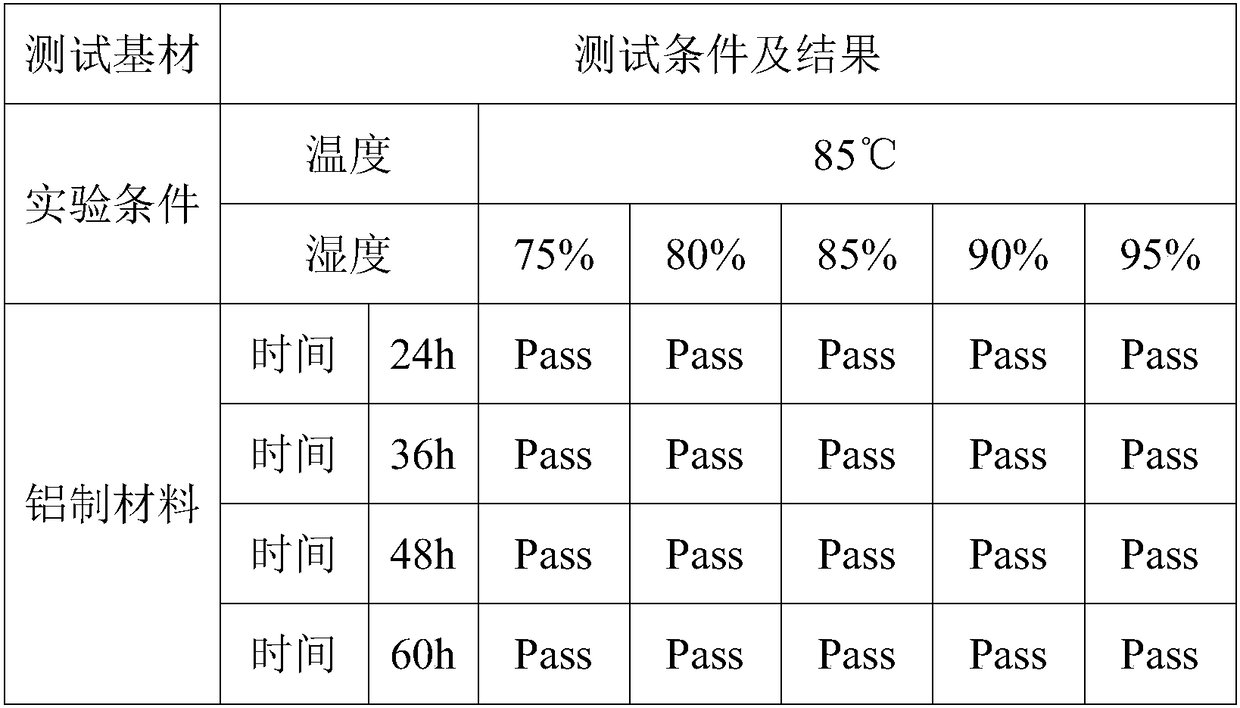

[0092] In step (1), the base material is a solid material, and the solid material is a block aluminum material, and any interface of the base material can be exposed to a damp heat test environment after the wet heat-resistant alternating coating is prepared on the surface of the base material.

[0093] In the step (1), the volume of the reaction chamber is 250 L, the temperature of the reaction chamber is controlled at 40° C., and the flow rate of the inert gas is 15 sccm.

[0094] In step (1), the base material performs planetary mot...

Embodiment 3

[0112] A method for preparing a multifunctional nano-protective coating with alternate discharge cycles, comprising the following steps:

[0113] (1) Place the substrate in the reaction chamber of the nano-coating preparation equipment, close the reaction chamber and continuously evacuate the reaction chamber, pump the vacuum in the reaction chamber to 130 millitorr, feed inert gas Ar, and start Motion mechanism to make the base material move;

[0114] In step (1), the base material is a solid material, and the solid material is a block polytetrafluoroethylene plate and an electrical component, and any interface of the block polytetrafluoroethylene plate can be exposed after the anti-mold coating is prepared on the surface Used in the GJB150.10A-2009 mold test environment, any interface of the electrical components can be exposed to the environment described in the international industrial waterproof grade standard IPX7 after the waterproof and electric breakdown resistant coa...

PUM

Login to View More

Login to View More Abstract

Description

Claims

Application Information

Login to View More

Login to View More - R&D

- Intellectual Property

- Life Sciences

- Materials

- Tech Scout

- Unparalleled Data Quality

- Higher Quality Content

- 60% Fewer Hallucinations

Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2025 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com