Device for plating metal by multiple beams of continuous long carbon fibers simultaneously and method thereof

A technology of long carbon fiber and electroplating metal, applied in the direction of electrolysis process, electrolysis components, cells, etc., can solve the problems of inconsistent pressure, different contact resistance, and inability to obtain a uniform electroplating layer of multiple bundles of carbon fibers, and achieve the solution of uneven thickness of the coating uniformity, increase production efficiency, and avoid fiber entanglement

- Summary

- Abstract

- Description

- Claims

- Application Information

AI Technical Summary

Problems solved by technology

Method used

Image

Examples

Embodiment 1

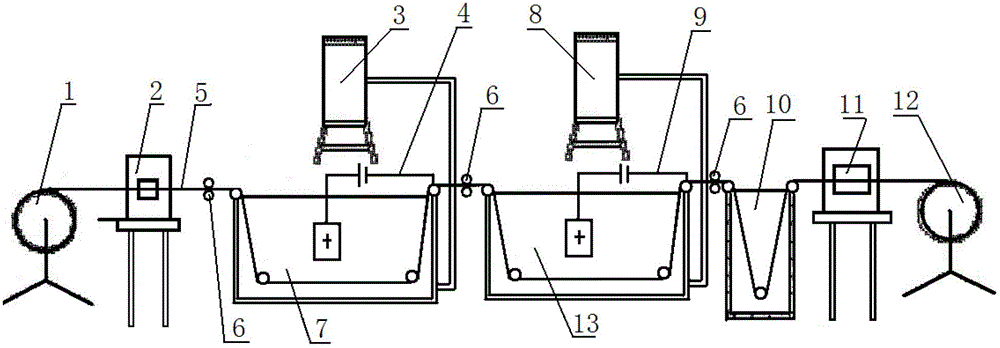

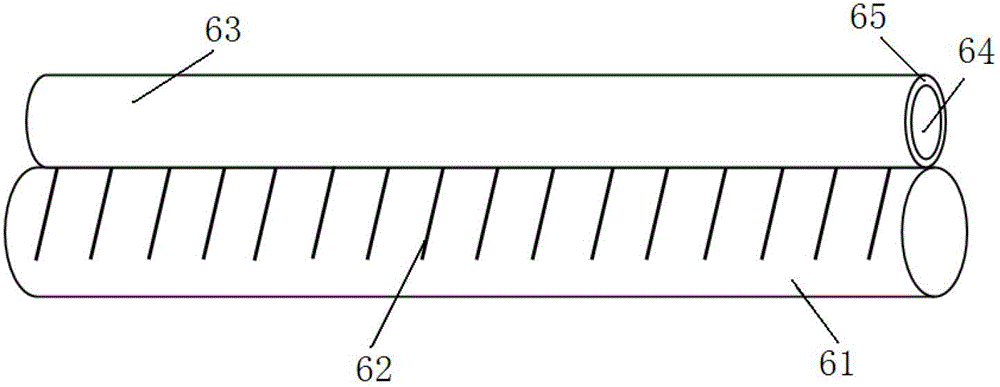

[0035] 16 bundles of continuous long carbon fibers (polyacrylonitrile base / bundle size 12k / single filament diameter 6-8μm) enter between the metal conductive roller and the pressure roller at the front end of each electroplating tank at the same time after degumming and cleaning, that is, the metal conducts electricity Above the roller is a 36 cm plastic-wrapped sponge press roller with the same length as the metal conductive roller. The diameter of the plastic core roller is 6 cm, and the thickness of the outer wrapped sponge layer is 1.0 cm. Each bundle of long carbon fibers It is powered by a DC power supply alone, and the following plating solution formulations are used in the two-stage electroplating tanks:

[0036] Copper sulfate pentahydrate 35g / L, potassium sodium tartrate 10g / L, sodium hydroxide 20g / L, anhydrous citric acid 25g / L;

[0037] Electrodeposition conditions are: pH=9;

[0038] 16 bundles of carbon fibers have a current range of 2.5-3.6 amps;

[0039] temp...

Embodiment 2

[0044] 24 bundles of continuous long carbon fibers (pitch base / bundle size 6k / single filament diameter 6-8μm) enter between the metal conductive roller and the pressure roller at the front of the electroplating tank at the same time after degumming and cleaning, that is, above the metal conductive roller is a A plastic core roller with a length of 28 cm (basically the same length as the metal conductive roller) is wrapped with a sponge layer on the outer layer. The diameter of the plastic core roller is 4 cm, and the thickness of the outer sponge layer is 1.5 cm. Each bundle of carbon fiber Powered solely by a DC power supply. The formula of the plating solution in the electroplating tank is: nickel sulfate hexahydrate 200g / L, sodium chloride 8g / L, boric acid 25g / L; sodium sulfate 18g / L; magnesium sulfate 25g / L; sodium dodecylsulfonate 0.1mL / L. The electrodeposition conditions are: pH=5.0; the current range of 24 bundles of carbon fibers is 1.2-1.8 amperes; temperature=25°C;...

PUM

| Property | Measurement | Unit |

|---|---|---|

| Thickness | aaaaa | aaaaa |

| Thickness | aaaaa | aaaaa |

Abstract

Description

Claims

Application Information

Login to View More

Login to View More - R&D

- Intellectual Property

- Life Sciences

- Materials

- Tech Scout

- Unparalleled Data Quality

- Higher Quality Content

- 60% Fewer Hallucinations

Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2025 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com