Ultra-light high-strength high-sound-absorption fiber-reinforced thermoplastic foamed composite board and preparation method thereof

A fiber-reinforced, composite plate technology, applied in the direction of chemical instruments and methods, melt spinning, synthetic resin layered products, etc., can solve the problems of difficult operation, environmental hazards, high operating requirements, etc., to reduce manufacturing costs and reduce production costs , Improve the effect of mechanical properties

- Summary

- Abstract

- Description

- Claims

- Application Information

AI Technical Summary

Problems solved by technology

Method used

Image

Examples

Embodiment 1

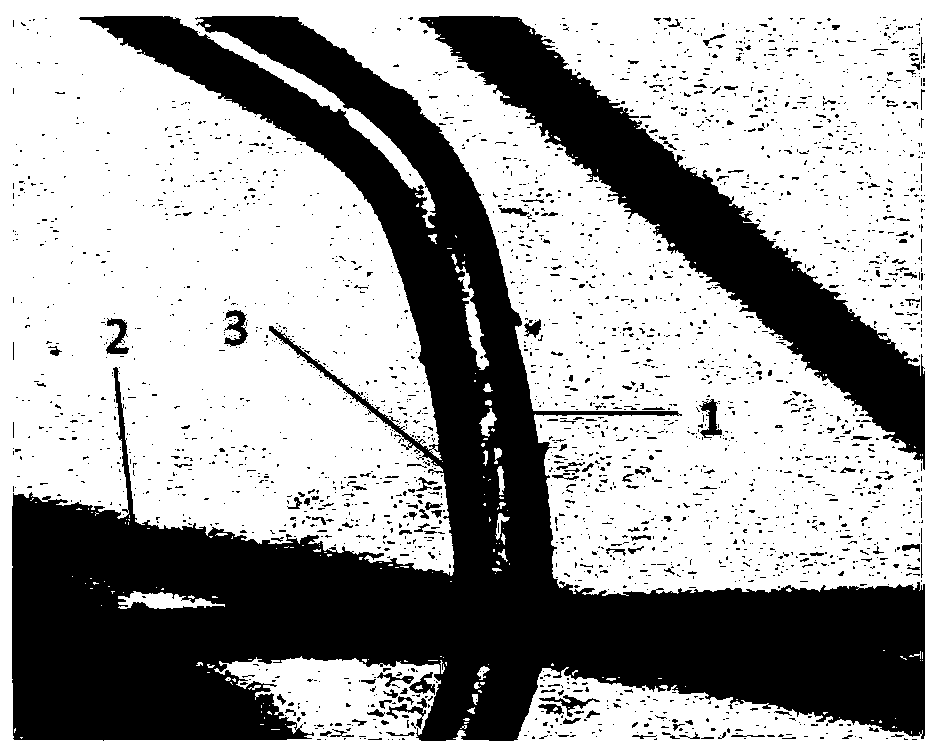

[0039] A kind of expandable thermoplastic fiber for preparing fiber-reinforced thermoplastic foam composite sheet, composed of polypropylene fiber 1 expandable microsphere foaming agent 3, such as figure 1 shown. The specific preparation method is as follows:

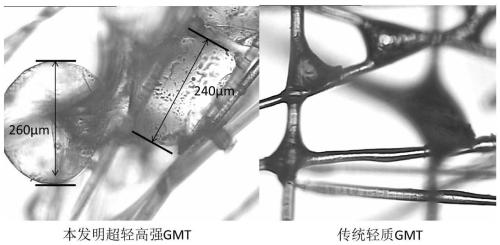

[0040] On a conventional melt spinning machine, the modified polypropylene powder with different particle sizes and the microsphere foaming agent 3 are blended and sent into the screw extruder, and the temperature range of each zone on the screw extruder is 170-205 °C The resulting melt is then extruded from the spinneret through a metering pump, and the melt is wound at a speed of 500-800m / min to obtain a coiled wire, which is then pre-drawn and heated at 100-140°C Hot drawing, the draw ratio is 5-9. The fibers are then heat-set at 100-120°C and retracted under stress at 90-110°C, and then wound into finished filaments (foamed fibers for short). The foamed fibers prepared by polypropylene powder with different parti...

Embodiment 2

[0046] An ultra-light and high-strength GMT composite sheet for preparing automobile bottom guards, which consists of polypropylene fiber 1 as a bonding matrix, glass fiber 2 as a reinforcement, and the expansion ratio of the sheet can be adjusted by changing the lattice point connection mode between the glass fibers 2 Efficacy of microsphere blowing agent 3 composition, such as figure 1 shown.

[0047] Its specific preparation method comprises the following steps:

Embodiment 3

[0084] An ultra-light and high-strength GMT composite sheet for preparing the roof of an automobile, which is made of ES fiber as a bonding matrix, hemp fiber as a reinforcement, and microspheres that have the effect of changing the grid connection mode between reinforcing fibers and adjusting the expansion ratio of the sheet. Agent 3 composition.

[0085] Its specific preparation method comprises the following steps:

[0086] (1) Blend and melt-spin microsphere foaming agent 3 and polypropylene fiber 1 at an initial foaming temperature of 210°C to form thermoplastic foamed polypropylene fiber 1 uniformly containing microsphere foaming agent 3, microsphere foaming agent 3 content is 9.5wt% of the mass of polypropylene fiber 1;

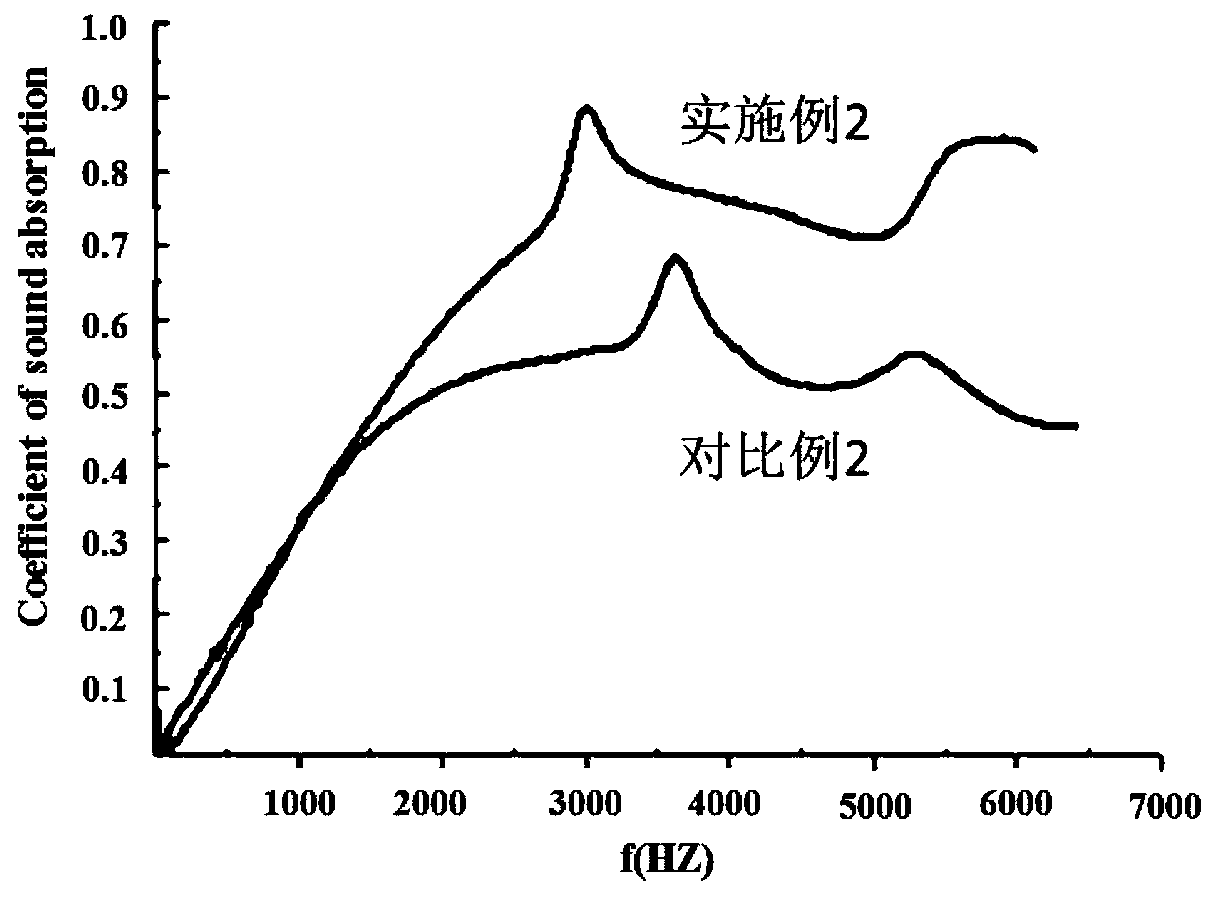

[0087] (2) Mix polypropylene fiber 1 and glass fiber 2 containing microsphere foaming agent 3 uniformly in the ratio of 45wt%: 55wt%, and through the non-woven process through opening, mixing, carding, laying, and acupuncture, it is obtained A blende...

PUM

| Property | Measurement | Unit |

|---|---|---|

| Areal density | aaaaa | aaaaa |

| Density | aaaaa | aaaaa |

| Areal density | aaaaa | aaaaa |

Abstract

Description

Claims

Application Information

Login to View More

Login to View More - R&D

- Intellectual Property

- Life Sciences

- Materials

- Tech Scout

- Unparalleled Data Quality

- Higher Quality Content

- 60% Fewer Hallucinations

Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2025 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com