Film cooling forming device of film-blowing machine

A film cooling and forming device technology, which is applied in the field of film cooling and forming devices of film blowing machines, can solve the problems of uneven thickness of film blank tubes, difficult design, high manufacturing cost, etc., achieve fast and uniform cooling speed, and highlight the essence Features, the effect of low manufacturing cost

- Summary

- Abstract

- Description

- Claims

- Application Information

AI Technical Summary

Problems solved by technology

Method used

Image

Examples

Embodiment Construction

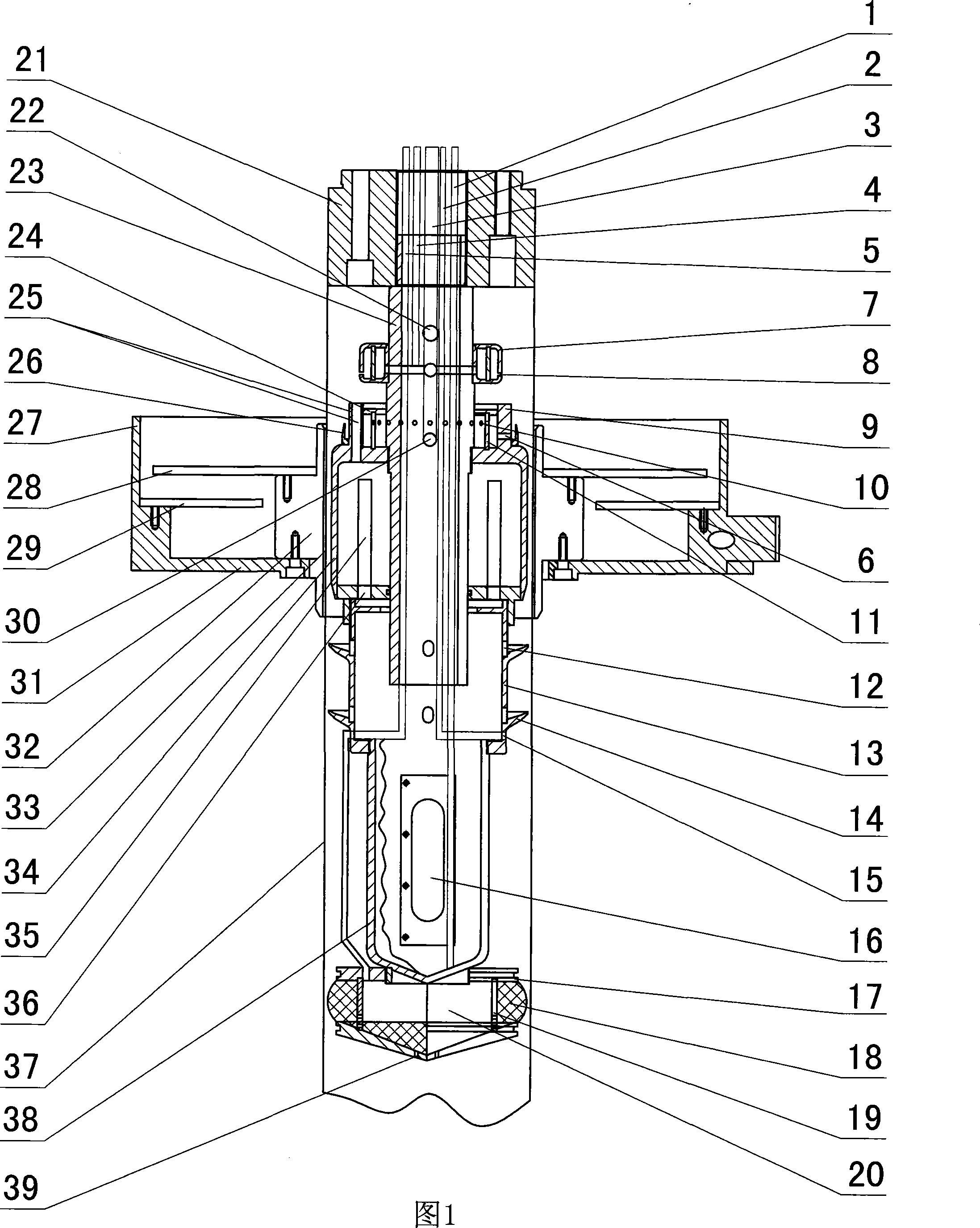

[0013] With reference to accompanying drawing, the film cooling forming device of this kind of film blowing machine includes air inlet tray 7, inner cooling water divider bucket 34, outer cooling water ring 27, wiper bucket 13, water receiving bucket 38 and water suction tank 17. Disk 7 is arranged on the top of inner cooling bucket 34, and said air inlet disk 7 communicates with an air inlet pipe 4, said air inlet disk 7 is provided with air outlet 8, and the top of said inner cooling water bucket 34 has exhaust hole 22, the exhaust hole 22 is arranged on an exhaust pipe 23; the upper end of the outer cooling water ring 27 is open, and it is set outside the inner cooling water dividing bucket 34, and there is a film blank tube channel 33 between the two. The outer cooling water ring 27 can move up and down, so that when the film base just starts to cool, the outer cooling water ring 27 can be moved away from the inner cooling water dividing bucket 34, so as to prevent the oute...

PUM

Login to View More

Login to View More Abstract

Description

Claims

Application Information

Login to View More

Login to View More - R&D

- Intellectual Property

- Life Sciences

- Materials

- Tech Scout

- Unparalleled Data Quality

- Higher Quality Content

- 60% Fewer Hallucinations

Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2025 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com