Graphene heat conduction film automatic material spraying and rolling device and material spraying rolling process

A technology of ene heat-conducting film and graphene, which is applied in the field of graphene heat-conducting film automatic spraying and calendering equipment and spraying and calendering technology, can solve the problem of the uniformity of the thickness of the rolling object, the thermal conductivity parameters and indicators cannot be reached, and the rolls are coaxial In order to achieve the effect of saving the heating and drying equipment, solving the problem of occupying the workshop space and avoiding short circuit

- Summary

- Abstract

- Description

- Claims

- Application Information

AI Technical Summary

Problems solved by technology

Method used

Image

Examples

Embodiment Construction

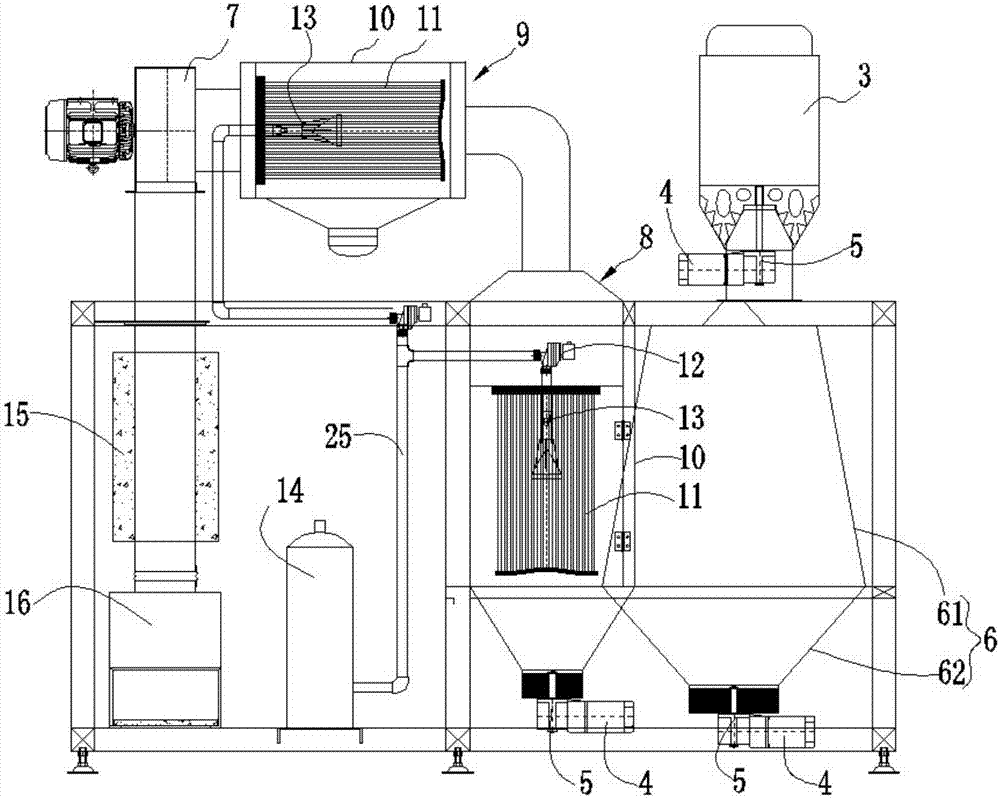

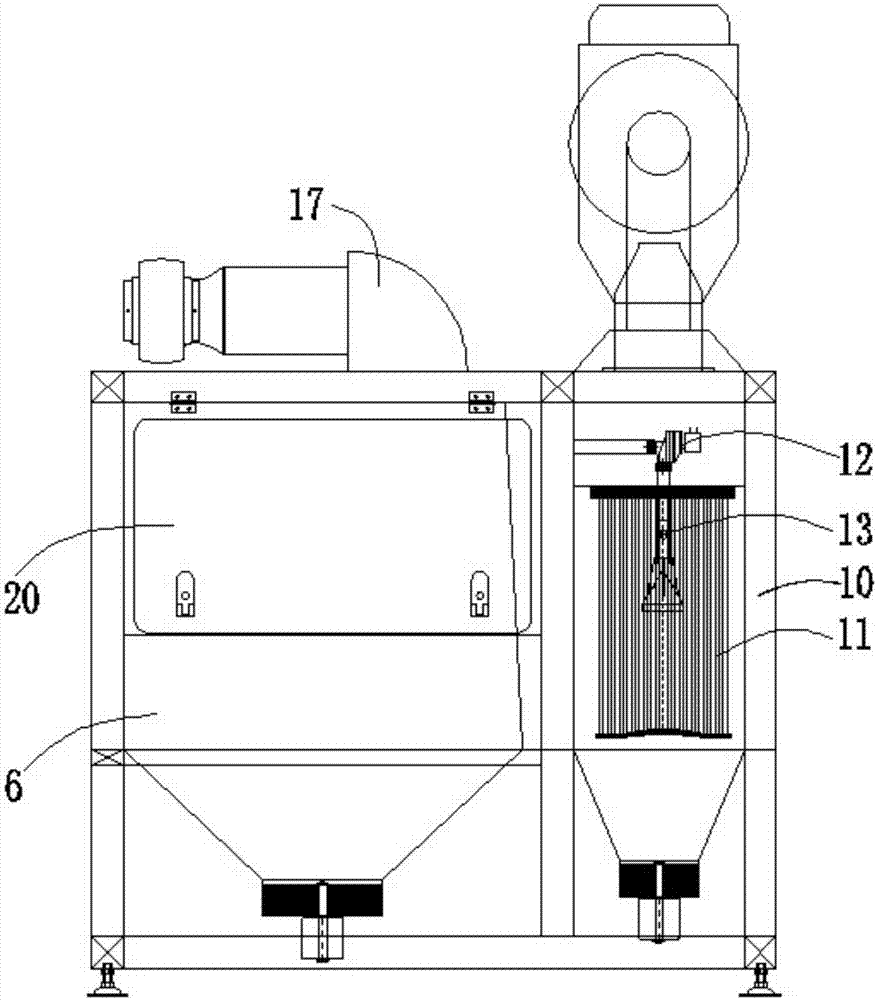

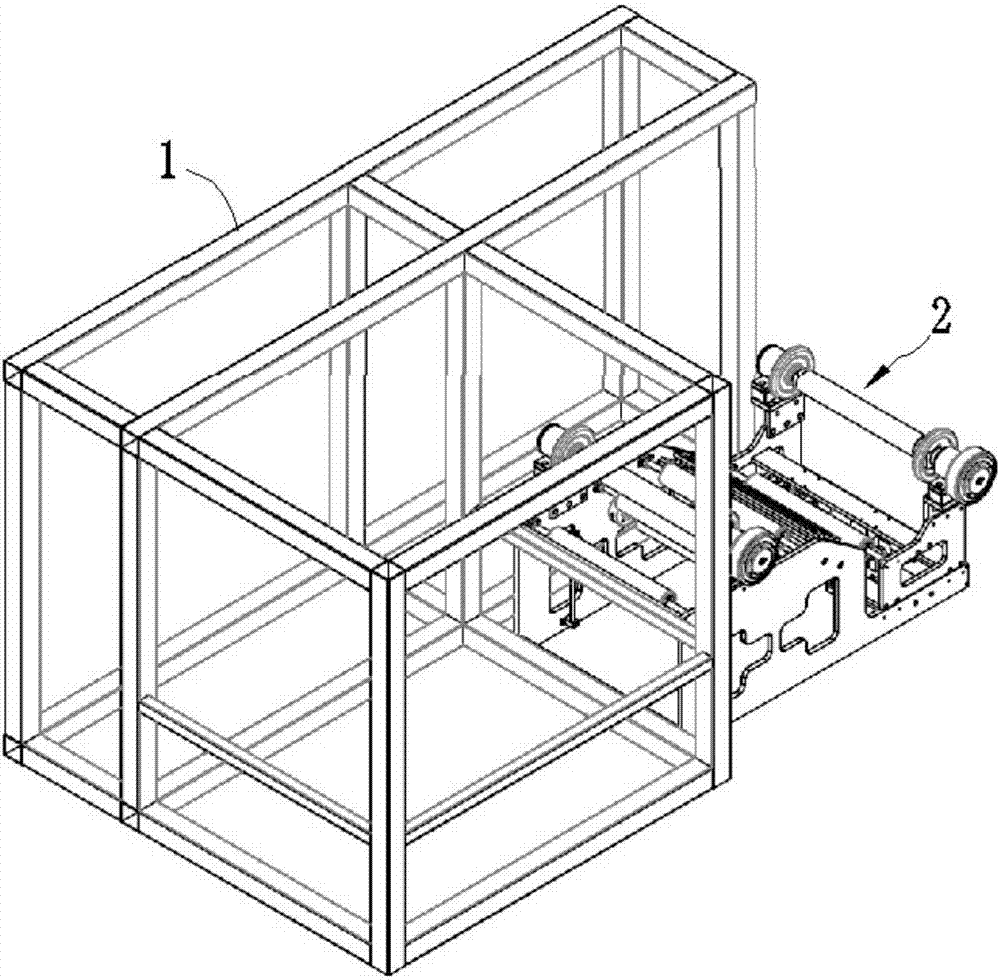

[0056] The technical solutions of the embodiments of the present invention will be clearly and completely described below in conjunction with the accompanying drawings of the present invention.

[0057] The invention discloses a graphene heat-conducting film automatic material spraying calendering equipment and material spraying calendering process, which utilizes the characteristics of graphene powder belonging to nanomaterials, and uses a spraying method to spray graphene powder onto the surface of copper foil to produce Thermally conductive film, and then the sprayed copper foil is further rolled to make the graphene powder on the surface of the copper foil more uniform. On the one hand, the present invention mainly solves the problem of low heat conduction parameters of the existing heat conduction film, and greatly improves the heat conduction parameters; and saves a large amount of power consumption because of the omission of heating and drying equipment, and also solves ...

PUM

Login to View More

Login to View More Abstract

Description

Claims

Application Information

Login to View More

Login to View More - R&D

- Intellectual Property

- Life Sciences

- Materials

- Tech Scout

- Unparalleled Data Quality

- Higher Quality Content

- 60% Fewer Hallucinations

Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2025 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com