Method for airborne thin-walled metal part and nonmetal part bonding

A technology for non-metal parts and metal parts, which is applied in the field of adhesive bonding of airborne thin-walled metal parts and non-metal parts, can solve problems such as deformation, achieve the effects of improving deformation, increasing processing costs, and wide application range

- Summary

- Abstract

- Description

- Claims

- Application Information

AI Technical Summary

Problems solved by technology

Method used

Image

Examples

Embodiment 1

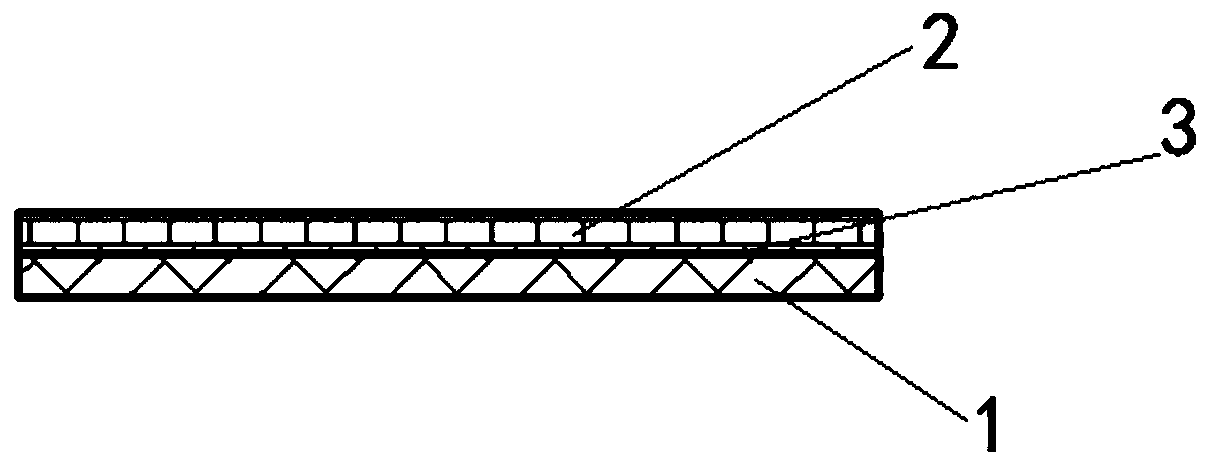

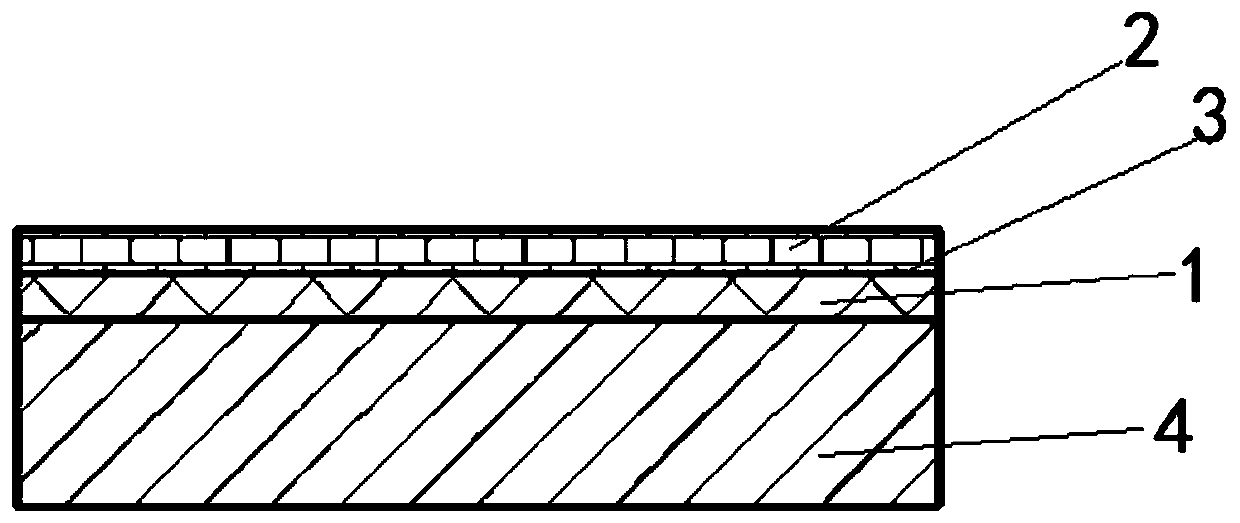

[0062] The material of the thin-walled non-metal parts in this example is epoxy glass fiber composite material, and the thin-walled metal parts are magnesium-aluminum alloy (aluminum alloy) parts. Process metal thin-walled parts, non-metallic thin-walled parts and glued tooling molds (aluminum film molds) respectively according to the existing digital models, and no pre-calibration processing has been carried out at this time.

[0063] The specific operation steps are as follows:

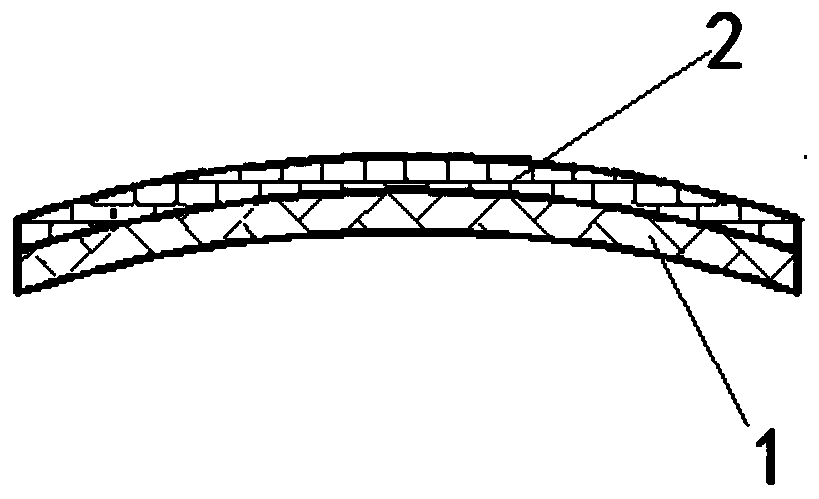

[0064] 1. Bonding: Preferably, 5 pairs of metal thin-walled parts and non-metallic thin-walled parts are bonded. After bonding, the two tips of the combined parts are deformed downward (negative direction of Z axis).

[0065] Among them, the specific operation of gluing is: attach the adhesive film to the metal thin-walled parts or non-metallic thin-walled parts. and use positioning pins to position them to prevent the dislocation of the two in the subsequent process; wrap the closed assembly with ...

PUM

Login to View More

Login to View More Abstract

Description

Claims

Application Information

Login to View More

Login to View More - R&D

- Intellectual Property

- Life Sciences

- Materials

- Tech Scout

- Unparalleled Data Quality

- Higher Quality Content

- 60% Fewer Hallucinations

Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2025 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com