Preparation method of coating with thiol compound as transition layer

A technology of mercapto compounds and transition layers, which is applied in coatings, metal material coating processes, gaseous chemical plating, etc., can solve the problems of limited application of parylene coatings, harsh coating preparation conditions, poor heat dissipation, etc.

- Summary

- Abstract

- Description

- Claims

- Application Information

AI Technical Summary

Problems solved by technology

Method used

Image

Examples

Embodiment 1

[0087] A kind of coating preparation method with mercapto compound as transition layer, comprises the following steps:

[0088] (1) Pre-processing:

[0089] Place the substrate in the reaction chamber of the nano-coating preparation equipment, close the reaction chamber and continuously evacuate the reaction chamber, pump the vacuum in the reaction chamber to 10 mTorr, pass in the inert gas Ar, and open the movement mechanism , causing the substrate to move in the reaction chamber;

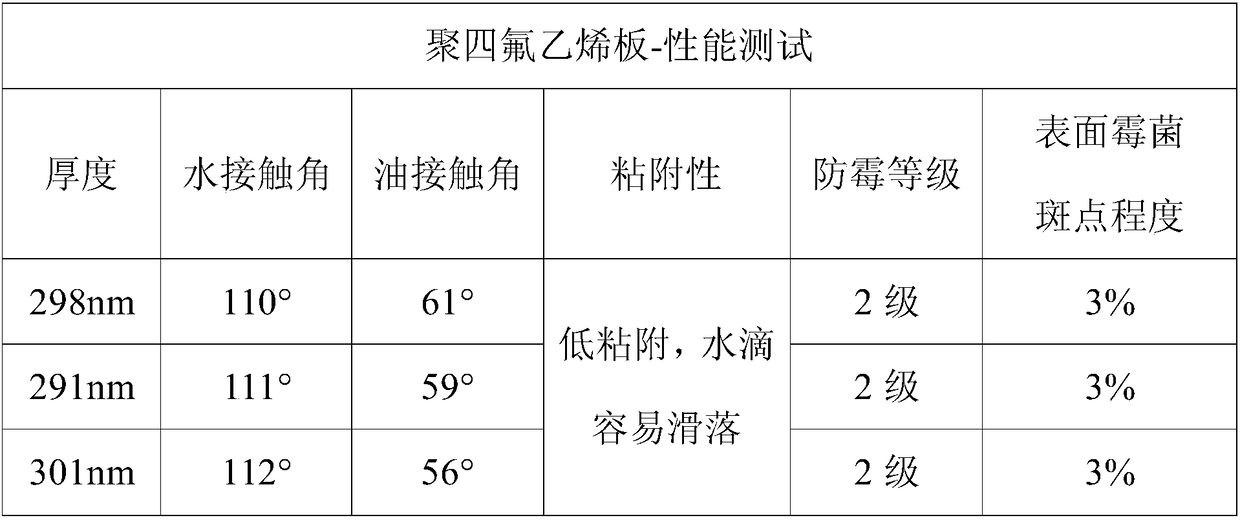

[0090] In step (1), the base material is a solid material, and the solid material is a block-shaped polytetrafluoroethylene plate.

[0091] In the step (1), the reaction chamber is a rotating chamber, the volume of the reaction chamber is 50 L, the temperature of the reaction chamber is controlled at 30° C., and the flow rate of the inert gas is 5 sccm.

[0092] In step (1), the substrate moves in the reaction chamber, and the substrate moves in a circular motion relative to the reaction chamber...

Embodiment 2

[0116] A kind of coating preparation method with mercapto compound as transition layer, comprises the following steps:

[0117] (1) Pre-processing:

[0118] Place the substrate in the reaction chamber of the nano-coating preparation equipment, close the reaction chamber and continuously evacuate the reaction chamber, evacuate the vacuum in the reaction chamber to 20 millitorr, feed inert gas He, start the movement mechanism, move the substrate;

[0119] In the step (1), the base material is a solid material, and the solid material is a block-shaped aluminum alloy anodized material.

[0120] In step (1), the reaction chamber is a cubic chamber with a volume of 250 L, the temperature of the reaction chamber is controlled at 40° C., and the flow rate of the inert gas is 15 sccm.

[0121] In step (1), the base material performs planetary motion, with a revolution speed of 1 revolution / min and an autorotation speed of 1.5 revolutions / min.

[0122] (2) Preparation of mercapto compo...

Embodiment 3

[0145] A kind of coating preparation method with mercapto compound as transition layer, comprises the following steps:

[0146] (1) Pre-processing:

[0147] Place the substrate in the reaction chamber of the nano-coating preparation equipment, close the reaction chamber and continuously evacuate the reaction chamber, pump the vacuum in the reaction chamber to 20 mTorr, and introduce a mixture of inert gases Ar and He The gas activates the movement mechanism to make the substrate move;

[0148] In the step (1), the base material is a solid material, and the solid material is a bulk alloy steel plate material and a PC plastic plate.

[0149] In the step (1), the reaction chamber is a rotating chamber with a volume of 480 L, the temperature of the reaction chamber is controlled at 50° C., and the flow rate of the inert gas is 60 sccm.

[0150] In step (1), the base material performs circular motion at a speed of 3 revolutions / min.

[0151] (2) Preparation of mercapto compound ...

PUM

Login to View More

Login to View More Abstract

Description

Claims

Application Information

Login to View More

Login to View More - R&D

- Intellectual Property

- Life Sciences

- Materials

- Tech Scout

- Unparalleled Data Quality

- Higher Quality Content

- 60% Fewer Hallucinations

Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2025 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com