High-flatness paint-free simulation ecological plate and manufacturing method thereof

A manufacturing method and flatness technology, applied in manufacturing tools, chemical instruments and methods, wood layered products, etc., can solve the problems of waste, high defective rate, uneven thickness and flatness, and achieve cost reduction and good environmental protection. , the effect of high flatness

- Summary

- Abstract

- Description

- Claims

- Application Information

AI Technical Summary

Problems solved by technology

Method used

Image

Examples

Embodiment 1

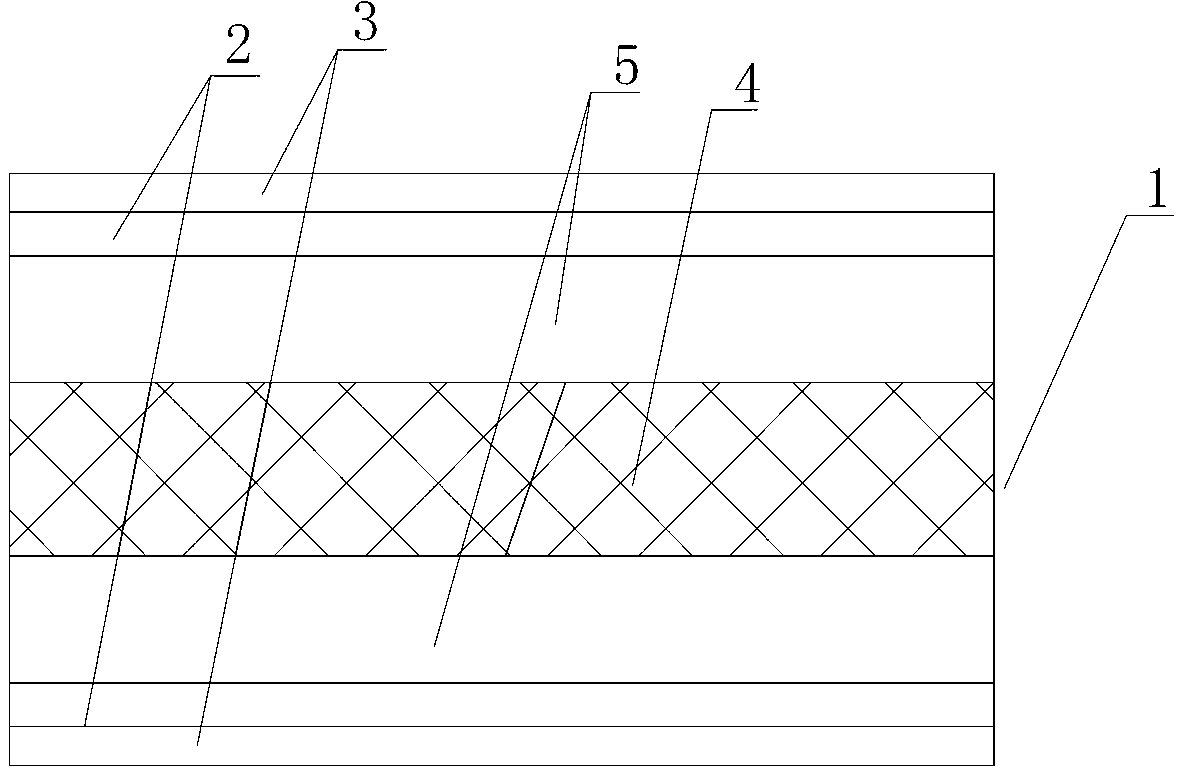

[0020] Embodiment 1: refer to figure 1 . A high-flatness paint-free simulation ecological board, including a substrate layer 1, at least one layer of technical wood veneer 2 is provided on the upper and lower sides of the substrate layer 1, and melamine impregnated paper 3 is pasted on the outside of the technical wood veneer 2. An adhesive is provided between the sheet 2 and the substrate layer 1 . The substrate layer 1 is a composite board composed of a middle board 5 and a core board 4 of multi-layer plywood or blockboard.

Embodiment 2

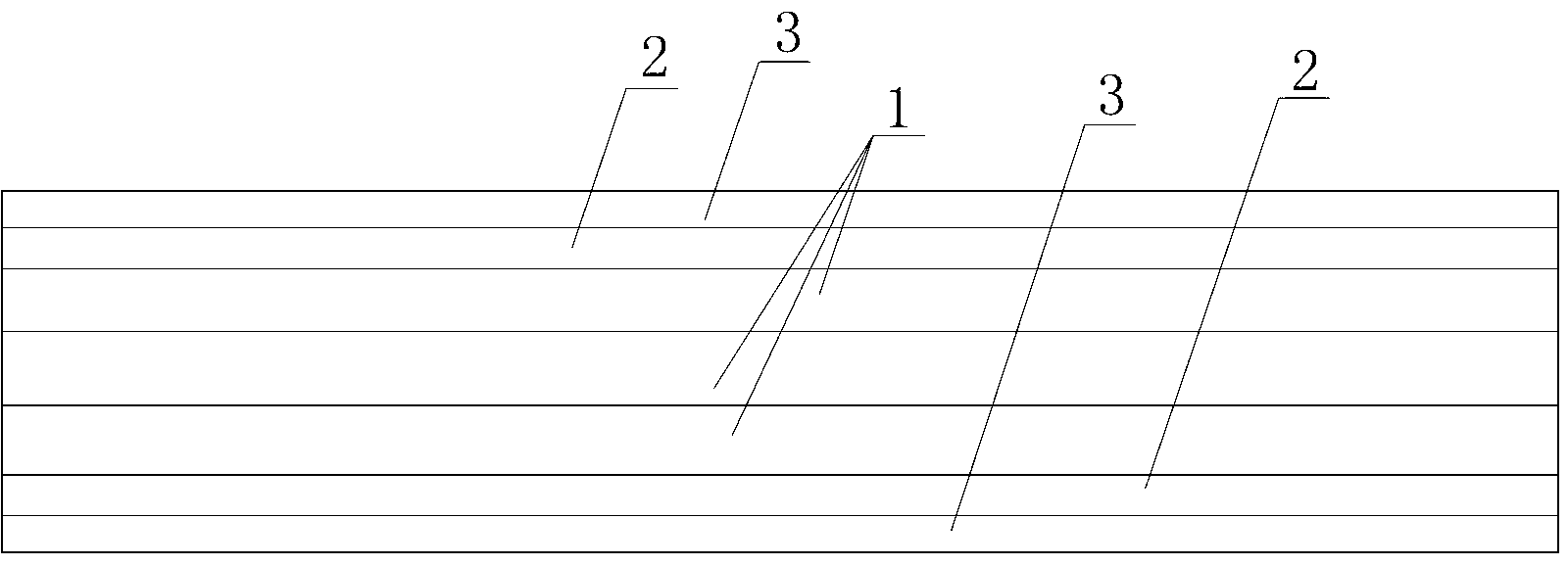

[0021] Embodiment 2: refer to figure 2 . The substrate layer 1 is a composite structure of multi-layer plywood 6 .

Embodiment 3

[0022] Embodiment 3: refer to figure 1 . A method for manufacturing a high-flatness paint-free simulation ecological board is characterized in that it comprises the following steps:

[0023] 1) Put the melamine-impregnated paper (3) and technical wood veneer (2) into the hot press for hot pressing and veneering. The hot pressing temperature is 110°C-130°C, the unit pressure is 1-1.6MPa, and the time is 3-6 Minutes, the composite board is cooled and stored after hot pressing;

[0024] 2) Apply adhesive on one side or both sides of the substrate layer (1) that has been sanded to a certain thickness, and pre-press the composite board prepared in the previous step and the substrate layer (1) that has been coated with glue. The unit pressure at room temperature is 0.3-0.7MPa, and the time is 20-60 minutes;

[0025] 3) After pre-pressing, the slab is sent to a hot press machine for hot-pressing and bonding. The hot-pressing temperature is 70-90°C, the unit pressure is 0.3-0.7MPa,...

PUM

Login to View More

Login to View More Abstract

Description

Claims

Application Information

Login to View More

Login to View More - R&D

- Intellectual Property

- Life Sciences

- Materials

- Tech Scout

- Unparalleled Data Quality

- Higher Quality Content

- 60% Fewer Hallucinations

Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2025 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com