Method for efficiently cutting silicon slice by electroplated diamond wires

A diamond wire and silicon wafer technology, applied in the field of high-efficiency cutting of silicon wafers with electroplating diamond wire, can solve the problems of low efficiency of cutting silicon wafers, achieve the effects of reducing cutting time, reducing production costs, and increasing production capacity

- Summary

- Abstract

- Description

- Claims

- Application Information

AI Technical Summary

Problems solved by technology

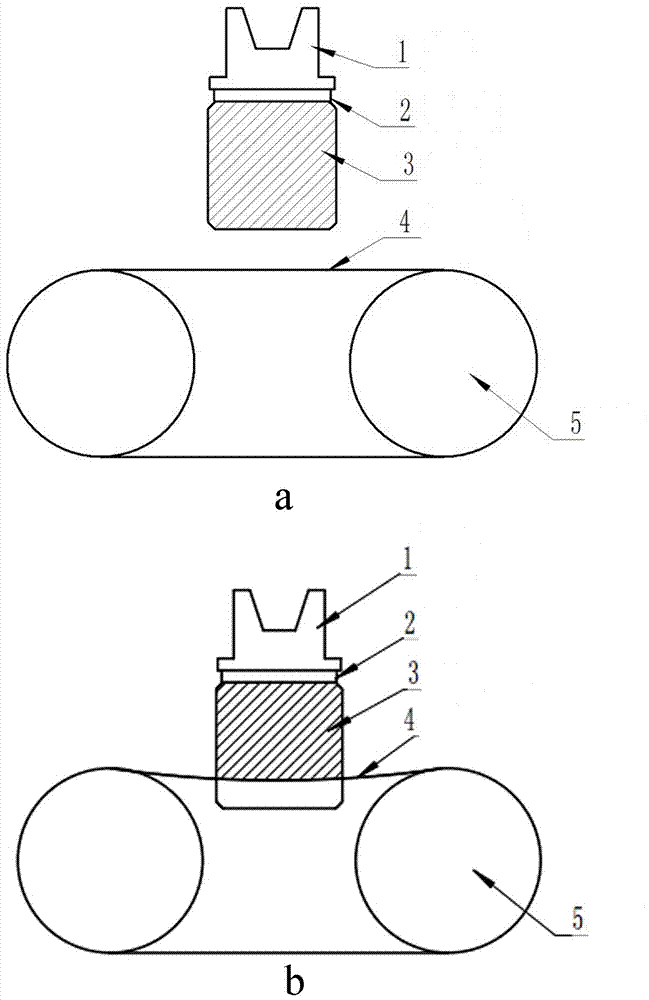

Method used

Image

Examples

Embodiment 1

[0048] Table 1 Example 1 cutting experiment data

[0049]

Embodiment 2

[0051] The difference with embodiment 1 is:

[0052] Step (2) Mix the purchased high-tech cutting fluid, Defeng defoamer, and water according to the mass ratio of 1:1:300, pour it into the cutting fluid tank, and set aside.

[0053] Such as image 3 As shown, it is an electron micrograph of the electroplated diamond wire used in this embodiment. In this embodiment, the electroplated diamond wire with a diameter of 70um is used as the cutting line, and the diamond particle density on the electroplated diamond wire is 300 ± 20 / mm , The diameter of the diamond particles is 8±2um, and the height of the diamond particles is 4.5um.

[0054] Before cutting, set the cutting depth to 6mm, and adjust the coolant flow rate to 0.5L / min. When the cutting depth reaches 6mm, the coolant flow rate is 160L / min.

[0055] During the cutting process, the cutting tension of the electroplated diamond wire is 12N, the line speed of the electroplated diamond wire is 1400m / min, the feed cutting spee...

PUM

| Property | Measurement | Unit |

|---|---|---|

| Diameter | aaaaa | aaaaa |

| Diameter | aaaaa | aaaaa |

| Diameter | aaaaa | aaaaa |

Abstract

Description

Claims

Application Information

Login to View More

Login to View More - R&D

- Intellectual Property

- Life Sciences

- Materials

- Tech Scout

- Unparalleled Data Quality

- Higher Quality Content

- 60% Fewer Hallucinations

Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2025 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com