Homogeneous electrochemical treatment method of inner surface of tubular workpiece

A treatment method and electrochemical technology, applied in the field of electrochemistry, can solve the problem of inability to prepare a coating with a uniform thickness or a uniform electrochemical treatment, and achieve the effects of optimizing the current density distribution, solving the uneven thickness and improving the uniformity.

- Summary

- Abstract

- Description

- Claims

- Application Information

AI Technical Summary

Problems solved by technology

Method used

Image

Examples

Embodiment 1

[0065] Such as figure 1 As shown, the copper anode is placed at the mouth of the two ends of the pipeline, and the simulation calculation is performed according to the set parameters in Table 1.

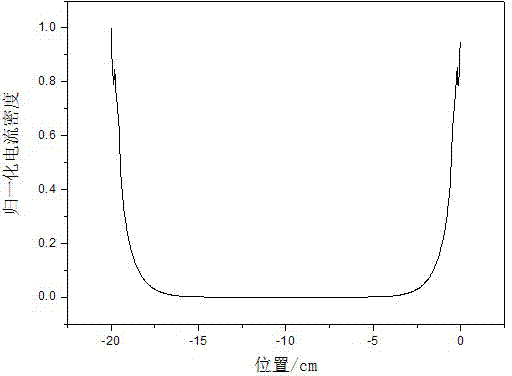

[0066] figure 1 Is the calculation model diagram of Example 1, figure 2 Is the current density distribution diagram of Example 1, image 3 It is the normalized current density distribution diagram obtained by simulation calculation in Example 1. figure 1 In the middle, the middle part is a pipe, and both sides are copper anodes.

[0067] From the calculation results of Example 1, it can be seen that when the electroplating anode is placed at the two ends of the pipeline, the current density distribution is mainly concentrated at the mouth of the pipeline. The farther away from the mouth, the smaller the current density, and the distance from the mouth is 5cm. The inner surface current density approaches zero. The normalized current density is distributed between 0 and 1, the normalized c...

Embodiment 2

[0069] A copper rod with a length of 22 cm and a diameter of 10 mm was inserted into the pipe as an anode, and the simulation calculation was performed according to the set parameters.

[0070] Figure 4 Is the calculation model diagram of Example 2, Figure 5 Is the current density distribution diagram of Example 2, Image 6 It is the normalized current density distribution diagram obtained by simulation calculation in Example 2.

[0071] It can be seen from the calculation results of Example 2 that after the electroplating anode is inserted into the pipeline, the current density distribution on the inner surface of the pipeline is significantly improved compared to Example 1, but the current density at the mouth of the electroplating pipeline is still significantly different from that in the middle of the pipeline. The current density is between 0.63 and 1, and the uniformity of coating thickness distribution is still poor.

Embodiment 3

[0073] A copper rod with a length of 2cm and a diameter of 10mm is inserted into the pipe as an anode, and it scans and moves up and down along the axis of the target pipe at a constant speed at a constant speed. The simulation calculation is carried out according to the set parameters.

[0074] Figure 7 Is the calculation model diagram of Example 3. Figure 8 Is the current density distribution diagram of Example 3, Picture 9 It is the normalized current density distribution diagram obtained by simulation calculation in Example 3.

[0075] It can be seen from the calculation results of Example 3 that during the uniform scanning movement of the anode up and down along the axis in the pipeline, the instantaneous current density distribution in the pipeline changes with the anode position, although the instantaneous current density distribution on the inner surface of the pipeline is not uniform , But after the superposition of the instantaneous current density distribution in the a...

PUM

Login to View More

Login to View More Abstract

Description

Claims

Application Information

Login to View More

Login to View More - R&D

- Intellectual Property

- Life Sciences

- Materials

- Tech Scout

- Unparalleled Data Quality

- Higher Quality Content

- 60% Fewer Hallucinations

Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2025 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com