Base material motion type device and method for preparing nano coating through plasma discharge

A plasma and nano-coating technology, applied in metal material coating process, coating, discharge tube and other directions, can solve the problems of loose coating structure, low production efficiency and high degree of powdering, improve deposition efficiency and improve production Effectiveness, the effect of improving deposition efficiency

- Summary

- Abstract

- Description

- Claims

- Application Information

AI Technical Summary

Problems solved by technology

Method used

Image

Examples

Embodiment 1

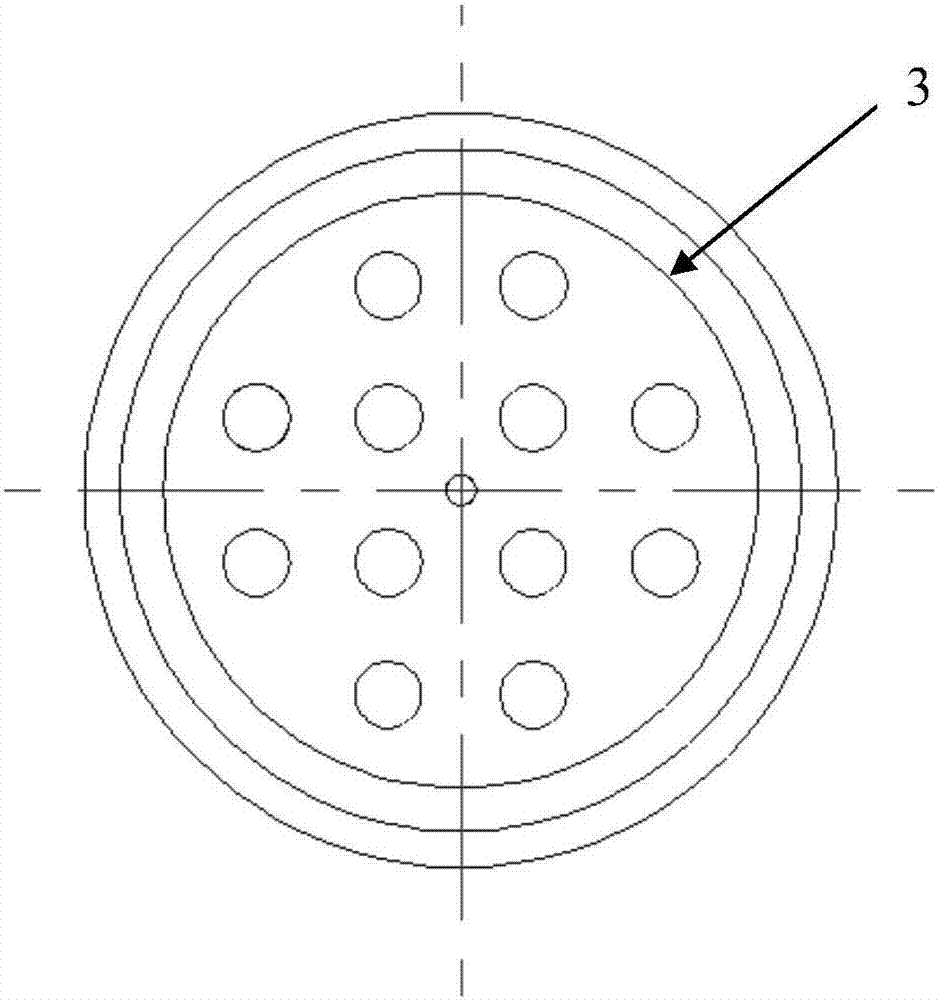

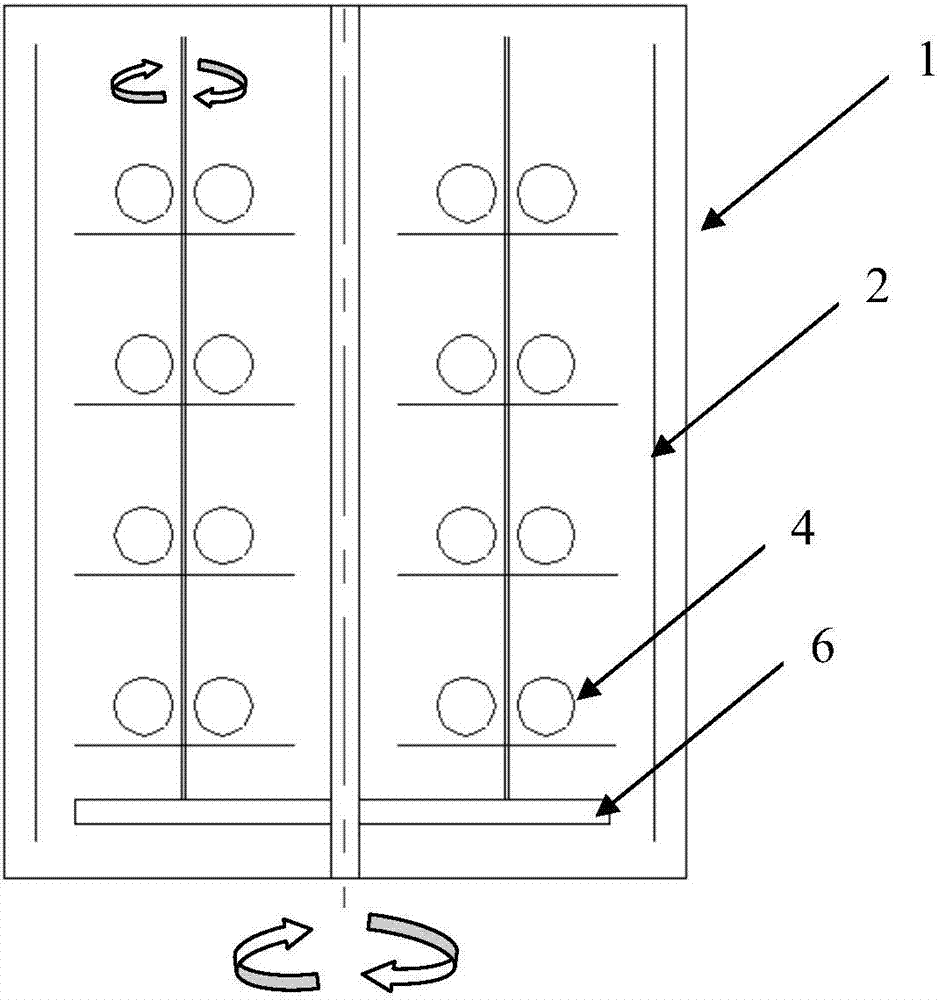

[0082] like figure 1 and figure 2 The device for preparing a nano-coating by substrate moving plasma discharge includes: a reaction chamber 1, characterized in that it also includes:

[0083] The electrode 2 for plasma discharge is arranged inside the space formed by the reaction chamber;

[0084] A pumping type vacuum exhaust device for forming a vacuum environment, the vacuum exhaust device is connected above the reaction chamber, the vacuum exhaust device includes an exhaust pipe, a primary vacuum pump and a secondary vacuum pump, and the exhaust pipe It is connected with the reaction chamber, and the exhaust pipe is connected with the secondary vacuum pump and the primary vacuum pump in turn;

[0085] Gas lines for carrier gas and monomer vapor introduction;

[0086] a substrate fixing device for installing a substrate, the substrate fixing device being arranged inside the space formed by the electrodes;

[0087] The base material fixing device is installed in the spa...

Embodiment 2

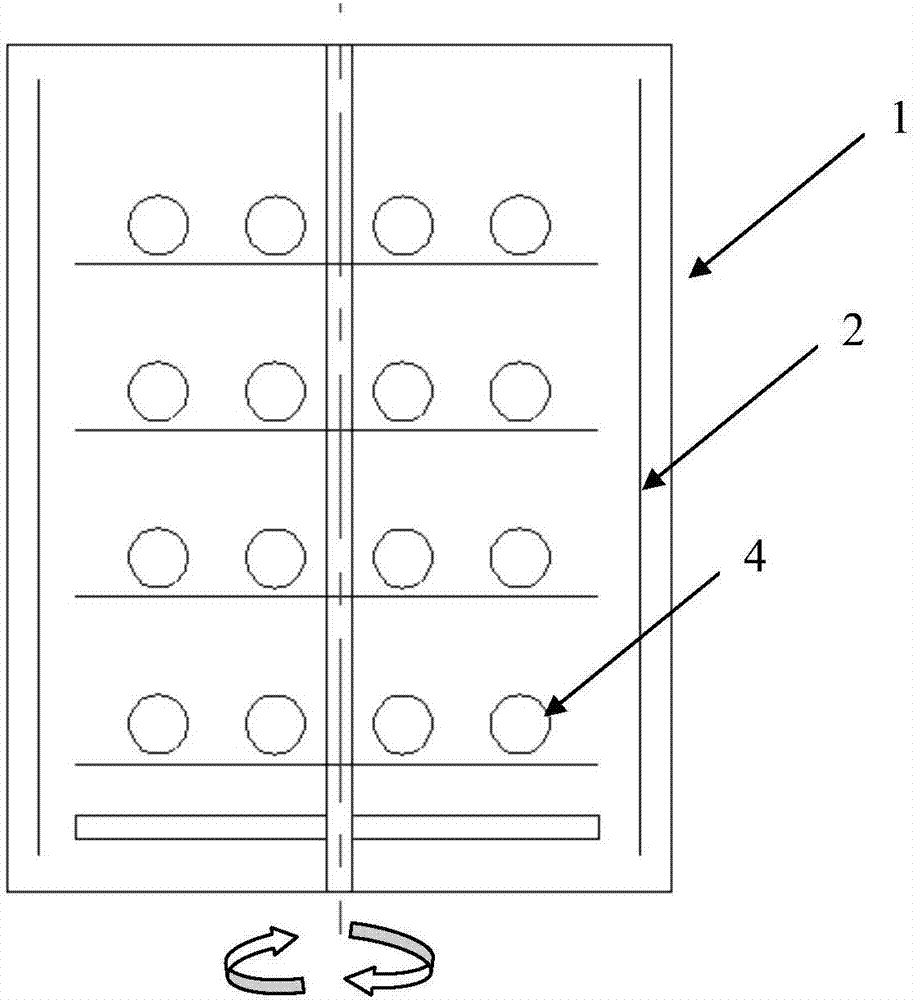

[0105] like image 3 and Figure 4 The device for preparing a nano-coating by substrate moving plasma discharge includes: a reaction chamber 1, characterized in that it also includes:

[0106] The electrode 2 for plasma discharge is arranged inside the space formed by the reaction chamber;

[0107] A pumping type vacuum exhaust device for forming a vacuum environment, the vacuum exhaust device is connected above the reaction chamber, the vacuum exhaust device includes an exhaust pipe, a primary vacuum pump and a secondary vacuum pump, and the exhaust pipe It is connected with the reaction chamber, and the exhaust pipe is connected with the secondary vacuum pump and the primary vacuum pump in turn;

[0108] Gas lines for carrier gas and monomer vapor introduction;

[0109] a substrate fixing device for installing a substrate, the substrate fixing device being arranged inside the space formed by the electrodes;

[0110] The base material fixing device is installed in the spa...

Embodiment 3

[0130] like Figure 5 and Image 6 The device for preparing a nano-coating by substrate moving plasma discharge includes: a reaction chamber 1, characterized in that it also includes:

[0131] The electrode 2 for plasma discharge is arranged inside the space formed by the reaction chamber;

[0132] A pumping type vacuum exhaust device for forming a vacuum environment, the vacuum exhaust device is connected above the reaction chamber, the vacuum exhaust device includes an exhaust pipe, a primary vacuum pump and a secondary vacuum pump, and the exhaust pipe It is connected with the reaction chamber, and the exhaust pipe is connected with the secondary vacuum pump and the primary vacuum pump in turn;

[0133] Gas lines for carrier gas and monomer vapor introduction;

[0134] a substrate fixing device for installing a substrate, the substrate fixing device being arranged inside the space formed by the electrodes;

[0135] The base material fixing device is installed in the spa...

PUM

| Property | Measurement | Unit |

|---|---|---|

| volume | aaaaa | aaaaa |

Abstract

Description

Claims

Application Information

Login to View More

Login to View More - R&D

- Intellectual Property

- Life Sciences

- Materials

- Tech Scout

- Unparalleled Data Quality

- Higher Quality Content

- 60% Fewer Hallucinations

Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2025 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com