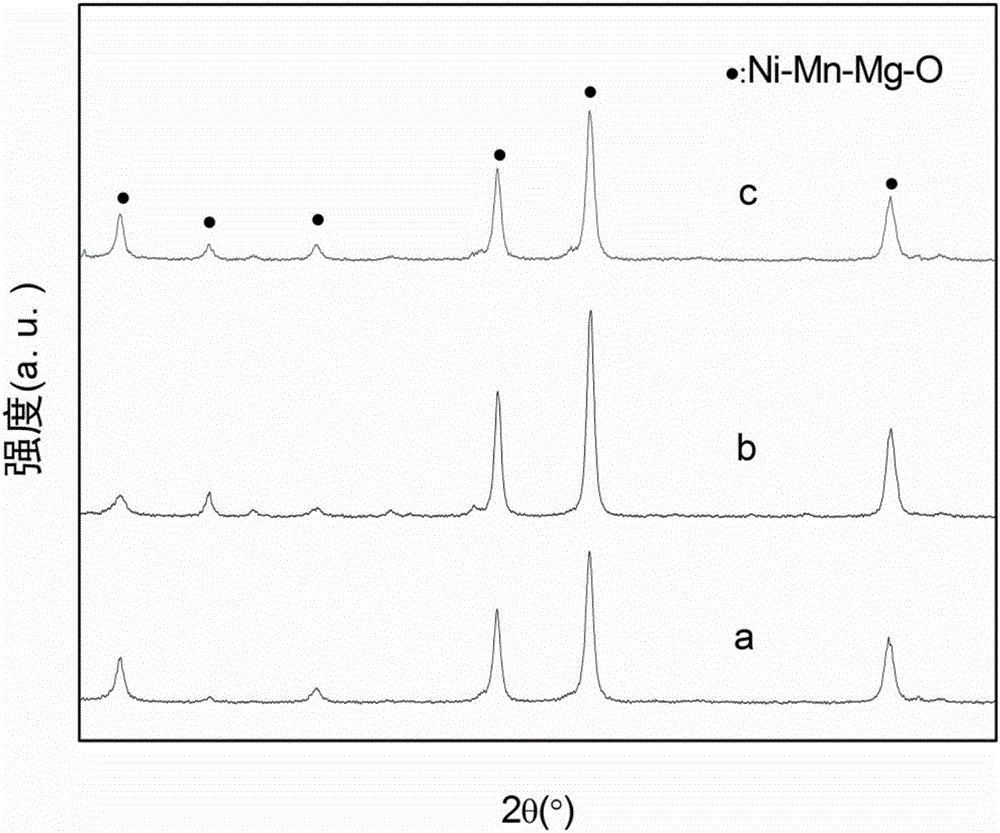

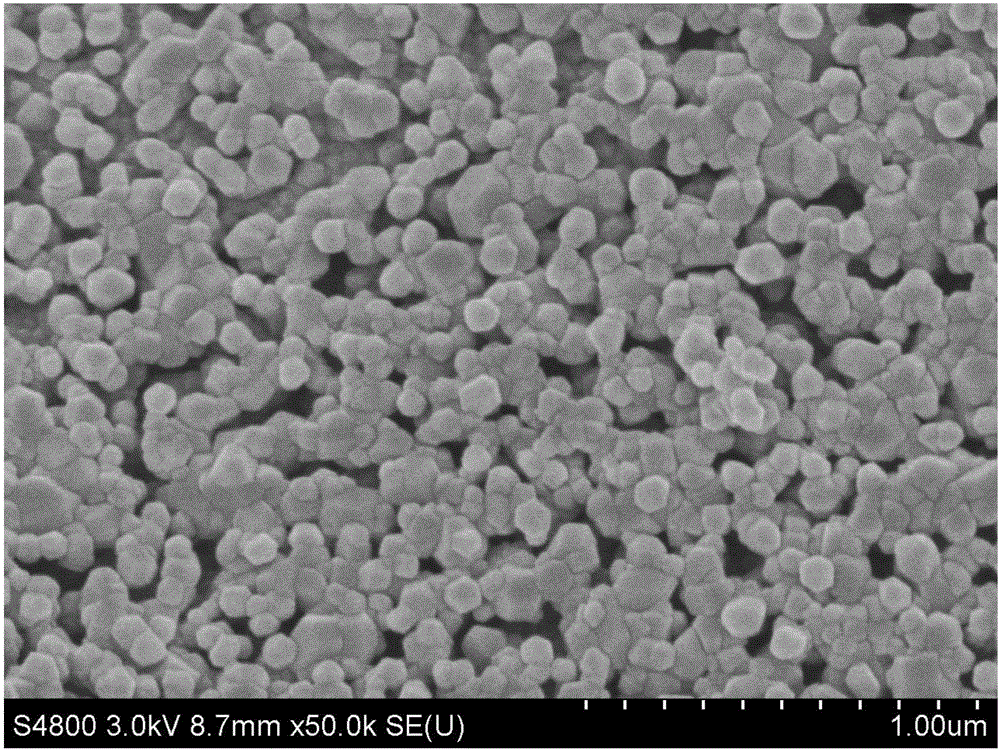

Preparation method of reforming catalyst oxide active component Ni-Mn-Mg-O

A technology for reforming catalysts and active components, applied in catalyst activation/preparation, chemical elements of heterogeneous catalysts, chemical instruments and methods, etc. Carbon, the effect of enhancing catalytic activity

- Summary

- Abstract

- Description

- Claims

- Application Information

AI Technical Summary

Problems solved by technology

Method used

Image

Examples

preparation example Construction

[0030] A preparation method for reforming catalyst oxide active component Ni-Mn-Mg-O, comprising the following steps:

[0031] Step 1: Design the composite oxide composition according to the molar ratio of n(NiO):n(MnO):n(MgO)=(2~4):2:1, first weigh a certain amount of nickel nitrate chemical reagent, and use deionized Water: Nickel nitrate is prepared into an aqueous solution with a concentration of 0.45 to 0.60 mol / L, and manganese nitrate and magnesium nitrate chemical reagents are weighed according to the designed molar ratio for subsequent use;

[0032] Step 2: Put the nickel nitrate aqueous solution in a numerically controlled temperature-adjusting ultrasonic instrument, slowly add the weighed manganese nitrate and magnesium nitrate under the action of ultrasonic waves at 40-50°C, and stir continuously at the same time, and wait until the solids are completely dissolved. , slowly drop the prepared KOH solution with a mass concentration of 20% into the beaker, adjust the ...

Embodiment 1

[0037] (1) The composite oxide composition is designed according to the molar ratio of n(NiO):n(MnO):n(MgO)=2:2:1. First weigh a certain amount of nickel nitrate chemical reagent, and use deionized water to prepare nickel nitrate into an aqueous solution with a concentration of 0.5 mol / L. Then take manganese nitrate and magnesium nitrate chemical reagents respectively according to the designed mol ratio for subsequent use.

[0038] (2) Put the aqueous solution of nickel nitrate in a numerically controlled temperature-adjusting ultrasonic instrument, add the weighed manganese nitrate and magnesium nitrate into it slowly under the action of ultrasonic waves at 50° C., and continuously stir at the same time. After the solid was completely dissolved, the prepared KOH solution with a mass concentration of 20% was slowly dropped into the beaker, the pH value was adjusted to 10, and ultrasonic stirring was continued for 30 min to obtain a copolymerized precipitate suspension.

[003...

Embodiment 2

[0042] (1) The composite oxide composition is designed according to the molar ratio of n(NiO):n(MnO):n(MgO)=3:2:1. First weigh a certain amount of nickel nitrate chemical reagent, and use deionized water to prepare nickel nitrate into an aqueous solution with a concentration of 0.5 mol / L. Then take manganese nitrate and magnesium nitrate chemical reagents respectively according to the designed mol ratio for subsequent use.

[0043] (2) Put the aqueous solution of nickel nitrate in a numerically controlled temperature-adjusting ultrasonic instrument, add the weighed manganese nitrate and magnesium nitrate into it slowly under the action of ultrasonic waves at 50° C., and continuously stir at the same time. After the solid was completely dissolved, the prepared KOH solution with a mass concentration of 20% was slowly dropped into the beaker, the pH value was adjusted to 10, and ultrasonic stirring was continued for 30 min to obtain a copolymerized precipitate suspension.

[004...

PUM

Login to View More

Login to View More Abstract

Description

Claims

Application Information

Login to View More

Login to View More - R&D

- Intellectual Property

- Life Sciences

- Materials

- Tech Scout

- Unparalleled Data Quality

- Higher Quality Content

- 60% Fewer Hallucinations

Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2025 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com