Method for microwave modulation of sludge-based hierarchical porous phosphorus-containing carbon for supercapacitor

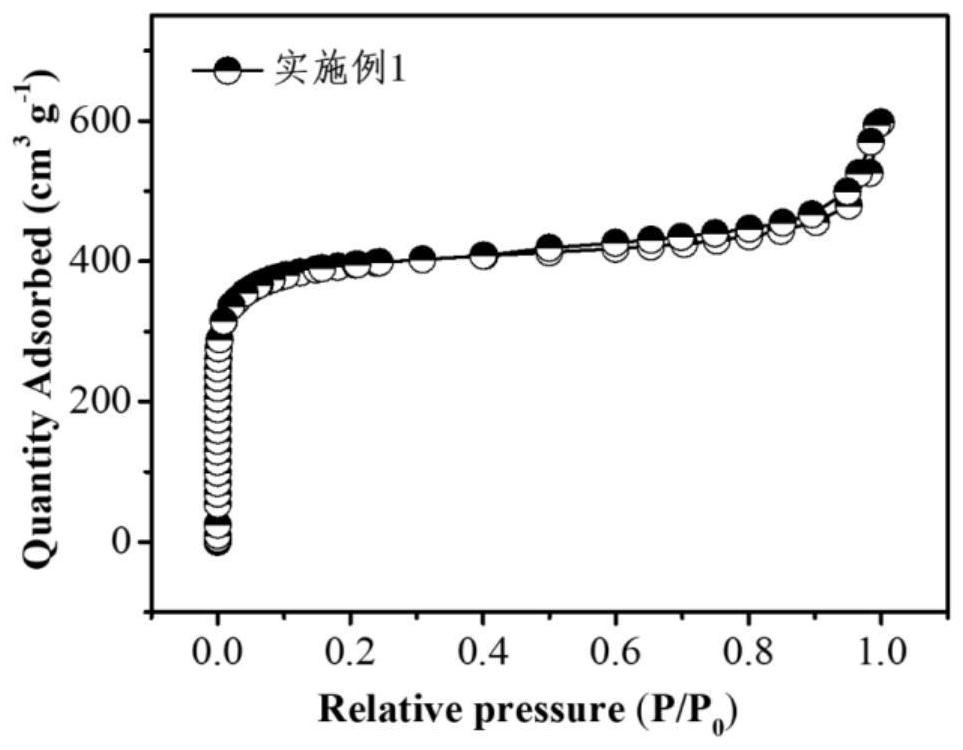

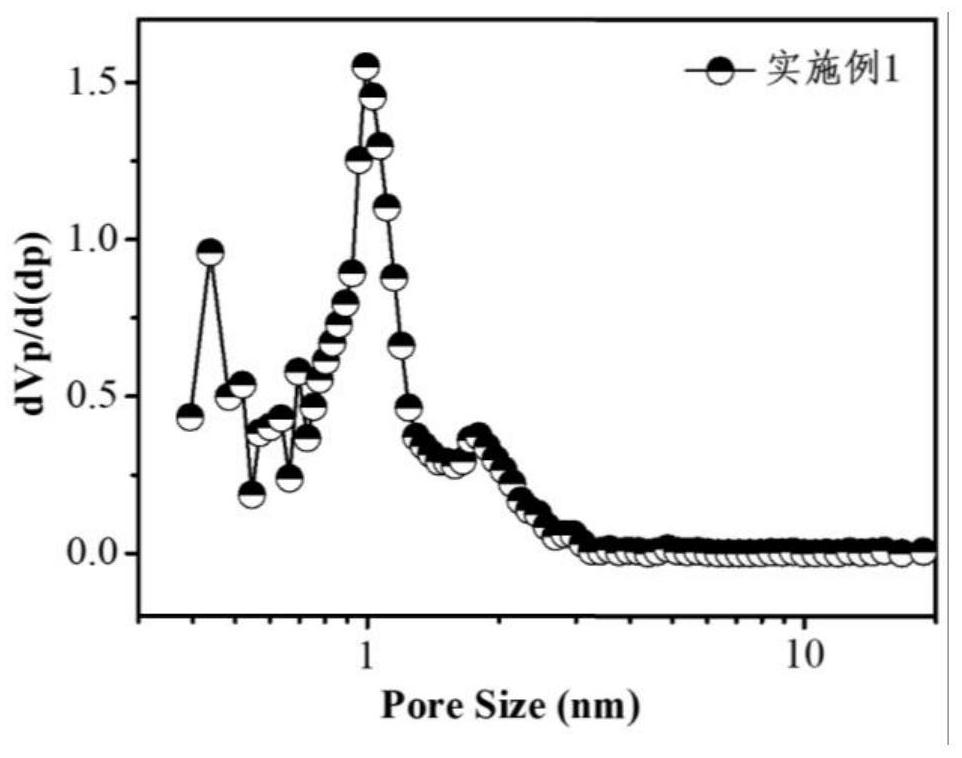

A supercapacitor, hierarchical porous technology, applied in the fields of resources and environment, can solve the problems of low functional group richness, low specific surface area and total pore volume, etc., to optimize the microscopic pore structure, improve conductivity, and improve the effect of specific surface area.

- Summary

- Abstract

- Description

- Claims

- Application Information

AI Technical Summary

Problems solved by technology

Method used

Image

Examples

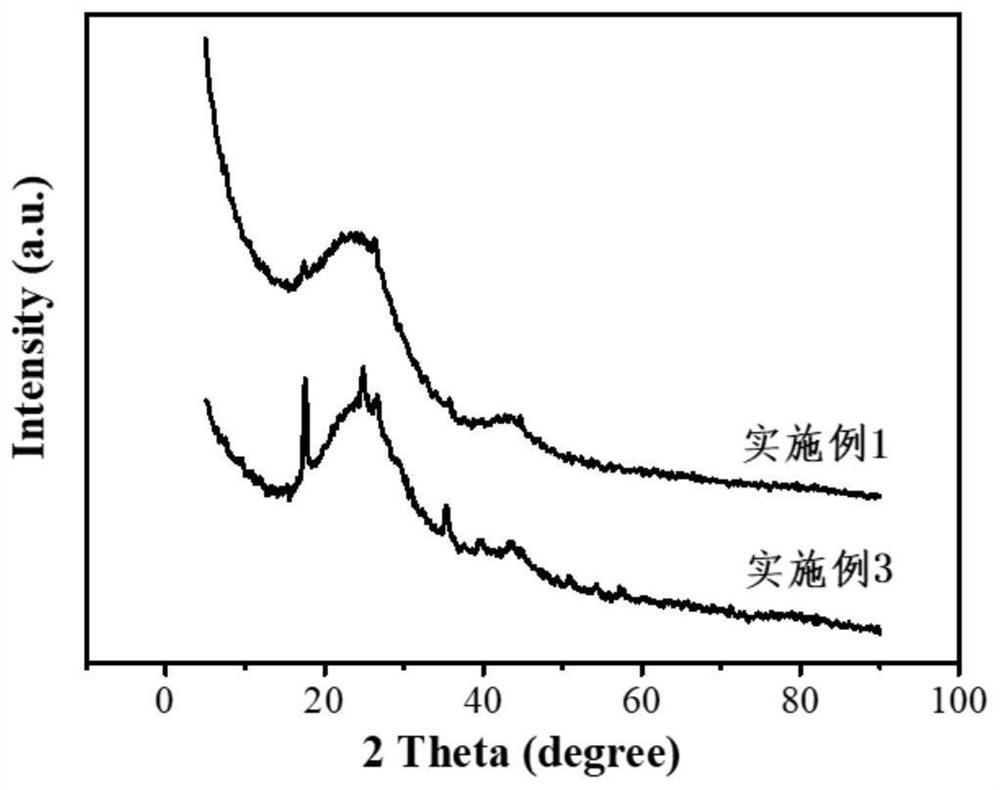

Embodiment 1

[0048] (1) Preparation of mixed sludge-based carbonization products

[0049] Take the remaining sludge from the municipal sewage treatment plant, filter 60%-80% of the water, dry it in an oven at 105°C for 12h / 18h / 24h to constant weight, and use the rapid ashing method to determine the proportion of volatile matter and ash in the sludge , and the results are shown in Table 1. It can be seen that the mass percentage of volatile substances in the sludge is as high as about 50% (the average value is 50.10%), and the CaCO 3 , SiO 2 The ash content mainly composed of other inorganic components is about 49% (the average value is 49.20%).

[0050] Volatile matter and ash proportion result in the sludge of table 1 embodiment 1

[0051]

[0052] a. dry base

[0053] After the sludge and bamboo chips with a carbon content of 40% to 50% were broken respectively, 4g of bamboo chips and 4g of sludge were weighed with a balance (the mass ratio of bamboo chips to sludge was 1:1), and ...

Embodiment 2

[0058] On the basis of Example 1, the present embodiment is different in that: in step (1), take by weighing 6g bamboo chips and 2g sludge (the mass ratio of bamboo chips and sludge is 3:1) with balance, use planetary ball mill and Several medium and small grinding balls were added and mixed waste biomass powder was obtained after 34 minutes of treatment. Put it into a 25*25*120mm microwave magnetic boat, and send it into the microwave cavity under the protection of a nitrogen atmosphere of 120ml / min. After testing the airtightness, set the parameters for power-on microwave to 1100W, and the final temperature is 700°C. In the constant temperature mode for 5 minutes, cool to room temperature under nitrogen atmosphere to obtain mixed sludge-based carbonization products.

Embodiment 3

[0066] On the basis of Example 1, the difference of this example is that in step (2), 3g of the mixed sludge-based carbonization product is mixed with the potassium hydroxide activator according to the carbon content in a mass ratio of 1:5 and ball milled for 5 minutes, then loaded The absorbing magnetic boat is sent into the microwave cavity, under microwave irradiation, under the protection of nitrogen atmosphere, the target temperature is raised to 800°C in stages, the heating process is: 300-500°C, the heating power is 500-1000W, and the temperature control time is 20min ; 500-600℃ temperature range, heating power 600-1200W, temperature control time 20min; 600-700℃ temperature range, heating power 600-1200W, temperature control time 20min; 700-800℃ temperature range, heating power 600-1200W, The temperature control time is 20 minutes; stay in the temperature range of 800°C, the heating power is 600-1200W, and the holding time is 20 minutes to fully activate the reaction to ...

PUM

| Property | Measurement | Unit |

|---|---|---|

| specific surface area | aaaaa | aaaaa |

Abstract

Description

Claims

Application Information

Login to View More

Login to View More - R&D

- Intellectual Property

- Life Sciences

- Materials

- Tech Scout

- Unparalleled Data Quality

- Higher Quality Content

- 60% Fewer Hallucinations

Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2025 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com