Method for preventing ended support of fully mechanized coal mining face from being stuck

A fully mechanized mining face and end support technology, which is applied to mine roof supports, pillars/supports, mining equipment, etc., can solve problems such as leaking, unfavorable, end support columns that cannot be moved without a stroke, and reduce damage. Effect

- Summary

- Abstract

- Description

- Claims

- Application Information

AI Technical Summary

Problems solved by technology

Method used

Image

Examples

Embodiment Construction

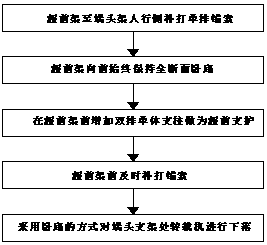

[0014] An example is the method of preventing crushing of the end support of a mine fully mechanized mining face, according to figure 1 As shown, the specific steps are as follows: (1) add a single row of anchor cables from the leading frame to the pedestrian side of the end bracket; (2) keep the full section of the leading frame forward; (3) add a double row of single anchor cables in front of the leading frame The pillar is used as the advance support; (4) The anchor cable is repaired in time before the advance frame; (5) The transfer machine at the end bracket is dropped by undercover.

[0015] Step (1) In order to prevent the roof from sinking further, install a single row of anchor cables in time on the pedestrian side from the leading frame to the end frame. The specification is Φ21.6mm and the length is 8.8m.

[0016] Step (2) Always keep the full section undercover in the range of 100m forward of the advance frame, and the height from the bottom of the roadway to the r...

PUM

Login to View More

Login to View More Abstract

Description

Claims

Application Information

Login to View More

Login to View More - R&D

- Intellectual Property

- Life Sciences

- Materials

- Tech Scout

- Unparalleled Data Quality

- Higher Quality Content

- 60% Fewer Hallucinations

Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2025 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com