Wall cement board small head nails

A technology of cement board and small head, applied in the field of cement nails, can solve the problems of unreasonable surface structure of cement nails, change in gripping force, large nail hole surface, etc., and achieve the effects of facilitating surface paint treatment, preventing rainwater infiltration, and being convenient to use.

- Summary

- Abstract

- Description

- Claims

- Application Information

AI Technical Summary

Problems solved by technology

Method used

Image

Examples

Embodiment Construction

[0018] The present invention will be further described below in conjunction with the accompanying drawings and embodiments.

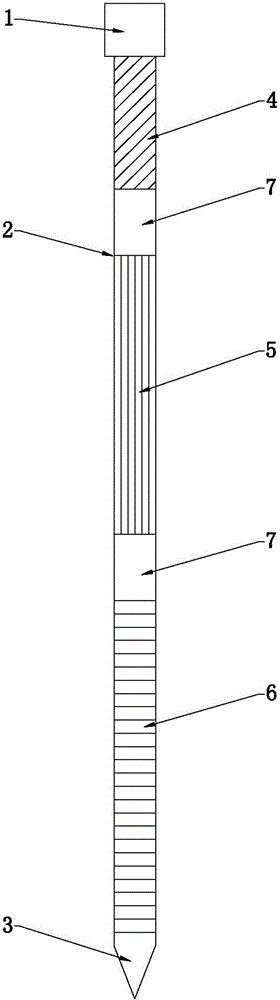

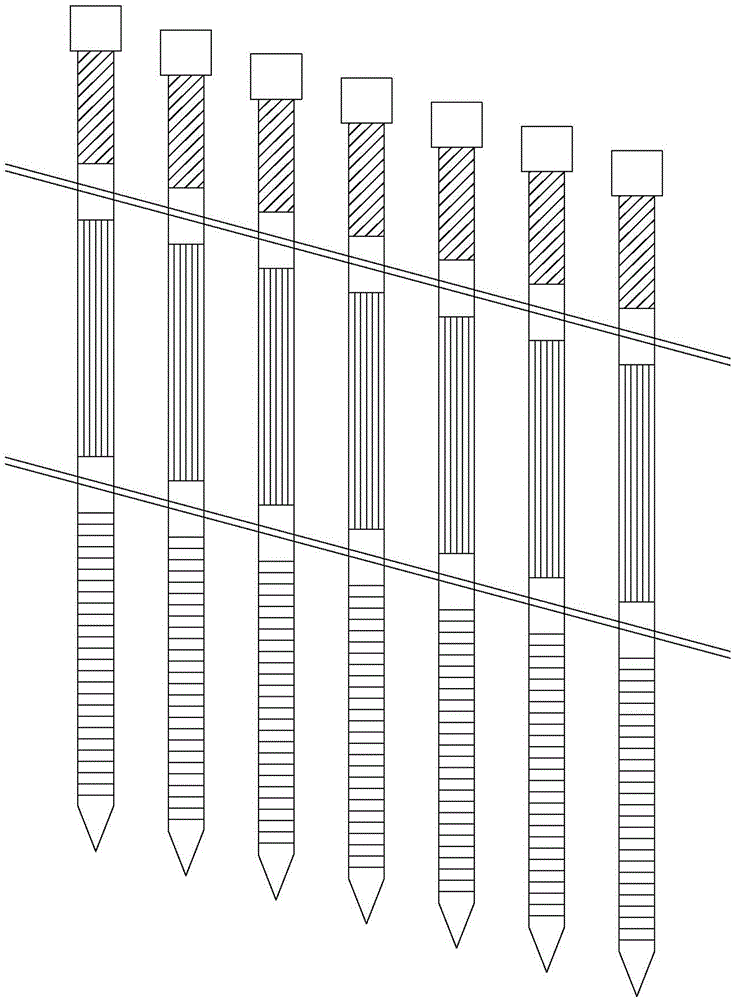

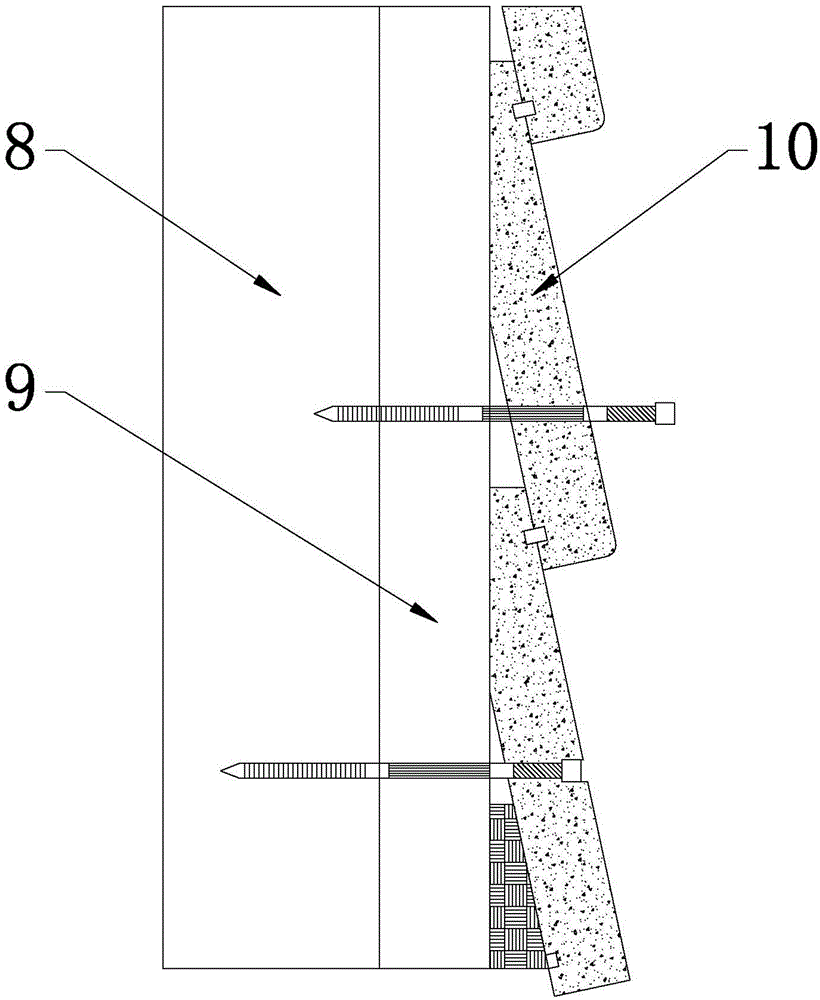

[0019] Such as Figure 1-3 Shown: a wall cement board small-headed nail, including a nail cap 1, a nail shank 2 and a nail tip 3 located at the top of the nail shank 2, the ratio of the diameter of the nail cap 1 to the diameter of the nail shank 2 is 1-1.5:1, Due to the reasonable diameter ratio between the nail cap 1 and the nail rod 2, the nail cap 1 can be submerged in the nail hole of the cement board 10 and the surface of the nail hole will not be too large, which is convenient for the surface paint treatment of the cement board 10 and can also prevent rainwater from infiltrating ; On the surface of the nail shank 2, from the nail cap 1 to the nail point 3, a threaded area 4, a straight grained area 5 and a ring grained area 6 are sequentially provided, and the threaded area 4 and the straight grained area 5, the straight grained area 5 and the an...

PUM

Login to View More

Login to View More Abstract

Description

Claims

Application Information

Login to View More

Login to View More - R&D

- Intellectual Property

- Life Sciences

- Materials

- Tech Scout

- Unparalleled Data Quality

- Higher Quality Content

- 60% Fewer Hallucinations

Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2025 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com