Multi-layer chain combined continuous drying system

A drying system and composite technology, applied in the field of multi-layer chain composite continuous drying system, can solve the problems of uneven heating of materials, slow drying speed, difficult temperature control, etc., and achieve the effect of strengthening the dehumidification effect

- Summary

- Abstract

- Description

- Claims

- Application Information

AI Technical Summary

Problems solved by technology

Method used

Image

Examples

Embodiment Construction

[0023] In order to more clearly illustrate the technical solutions of the embodiments of the present invention, the following will briefly introduce the accompanying drawings that need to be used in the embodiments. Obviously, the accompanying drawings in the following description are some embodiments of the present invention. Ordinary technicians can also obtain other drawings based on these drawings on the premise of not paying creative work.

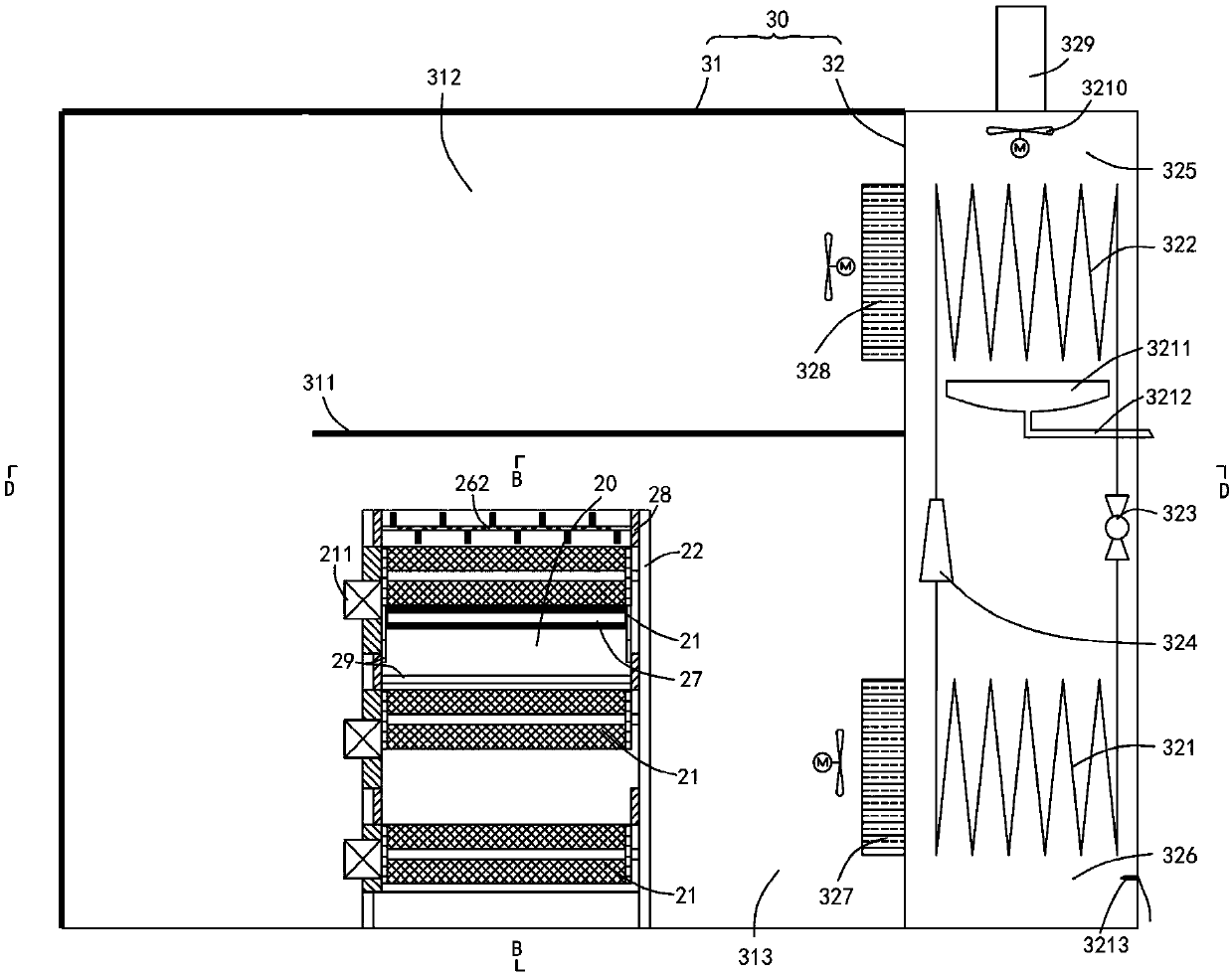

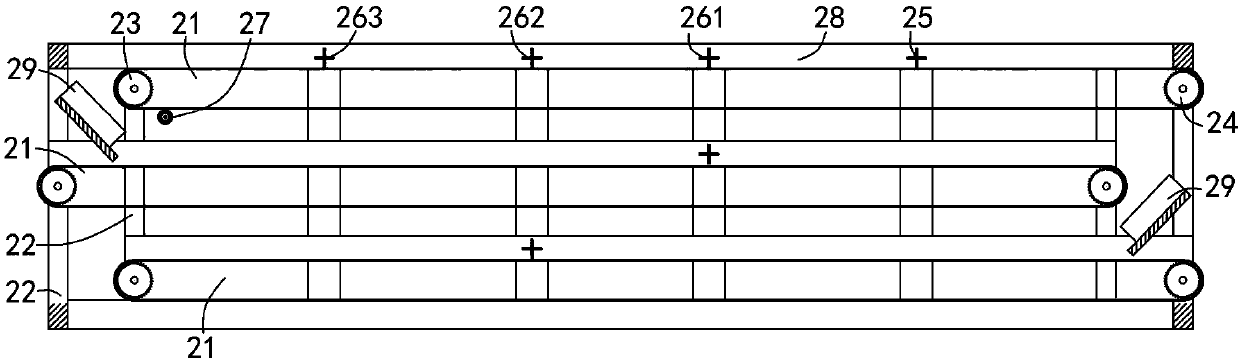

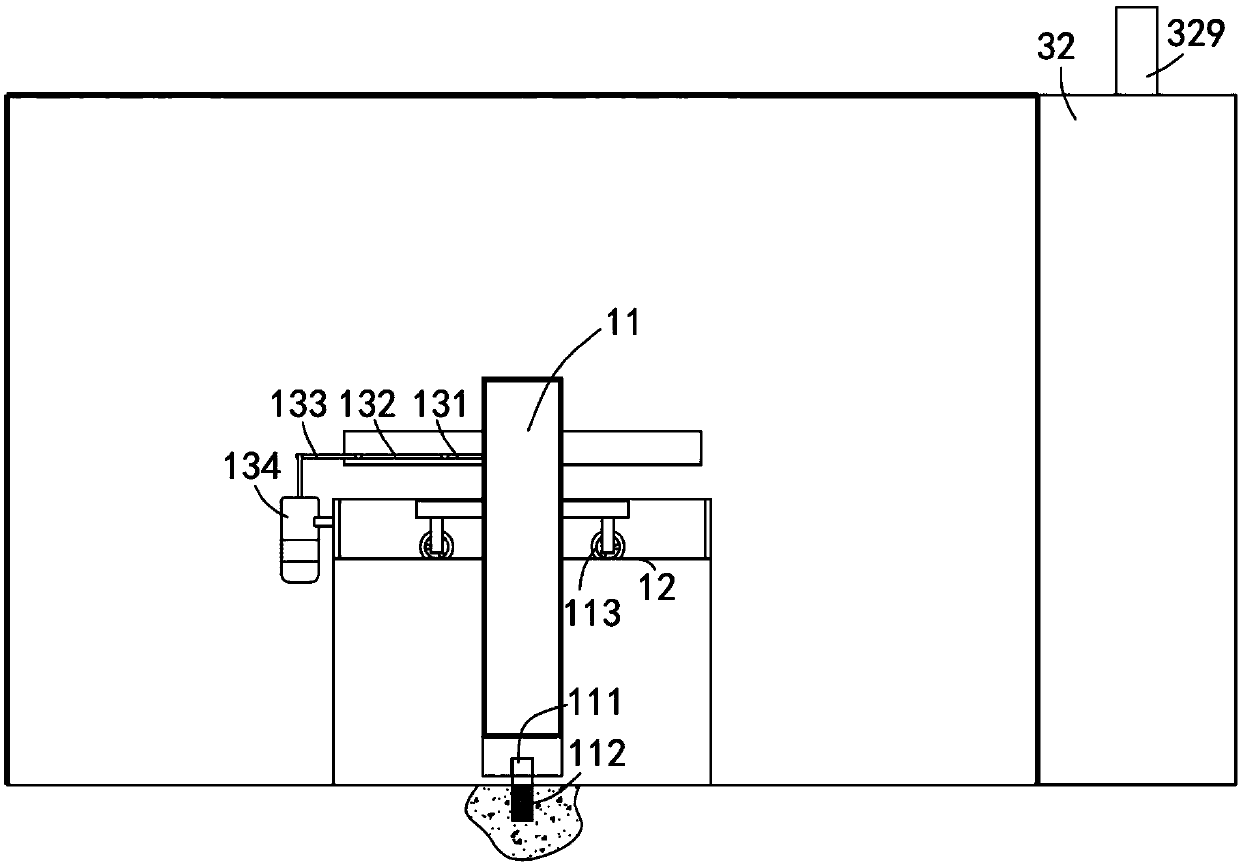

[0024] see Figure 1 to Figure 4 , the embodiment of the present invention provides a multi-layer chain composite continuous drying system, including a swing feeder 10, a chain-type multi-layer mesh belt 20, and a heat pump drying room 30; the swing feeder 10 can be multi-layered along the chain The layer mesh belt 20 reciprocates in the width direction to evenly arrange the baked materials in the width direction of the mesh belt at the feeding end of the chain type multilayer mesh belt 20; the chain type multilayer mesh belt 20 inclu...

PUM

Login to View More

Login to View More Abstract

Description

Claims

Application Information

Login to View More

Login to View More - R&D

- Intellectual Property

- Life Sciences

- Materials

- Tech Scout

- Unparalleled Data Quality

- Higher Quality Content

- 60% Fewer Hallucinations

Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2025 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com