A mining method for inclined medium-thick metal ore body

A mining method and technology for thick metal, applied in surface mining, underground mining, special mining, etc., can solve the problems of ore body dilution loss, etc., and achieve the effect of improving blasting effect, uniform arrangement of hole network parameters, and improving technical and economic indicators

- Summary

- Abstract

- Description

- Claims

- Application Information

AI Technical Summary

Problems solved by technology

Method used

Image

Examples

Embodiment

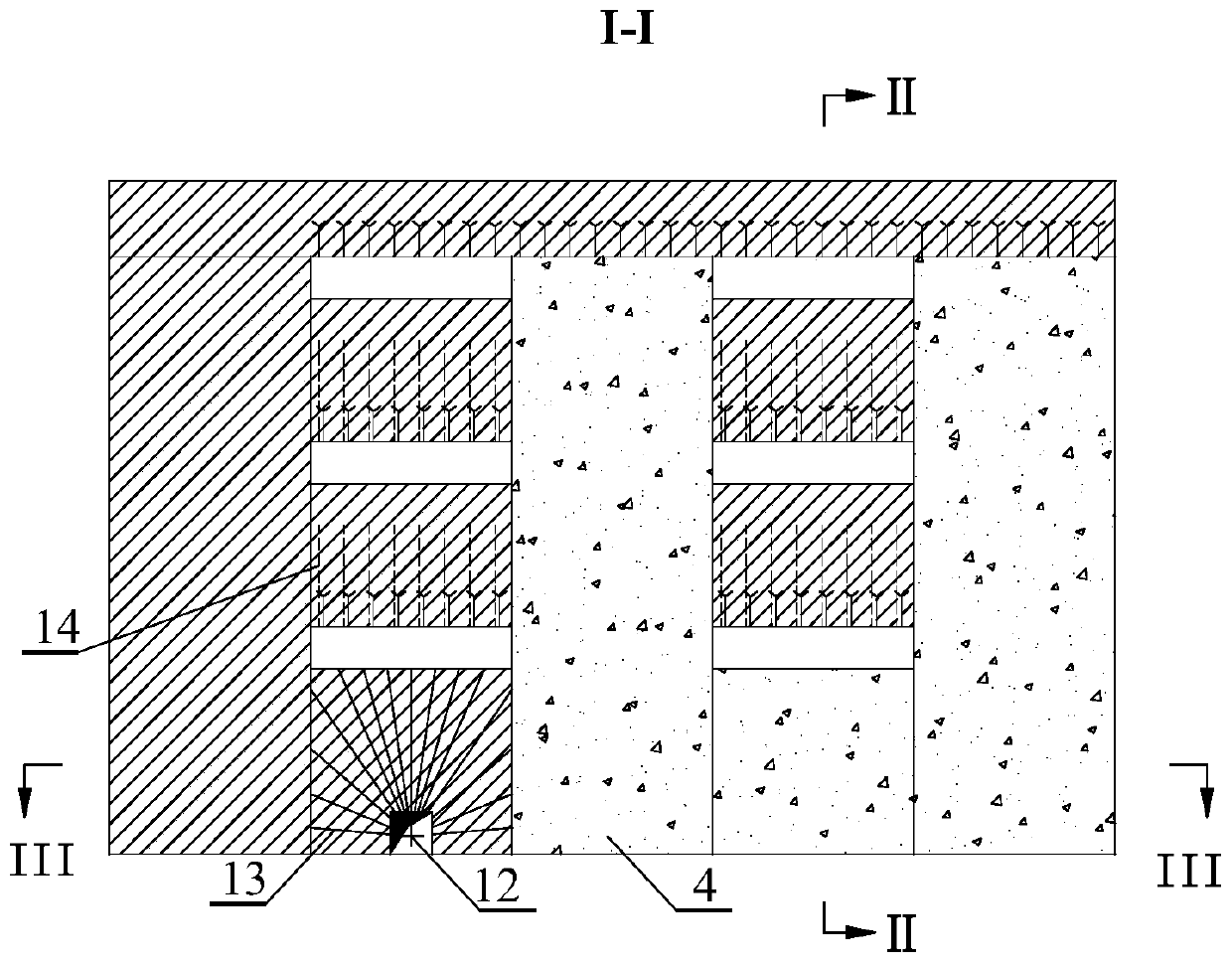

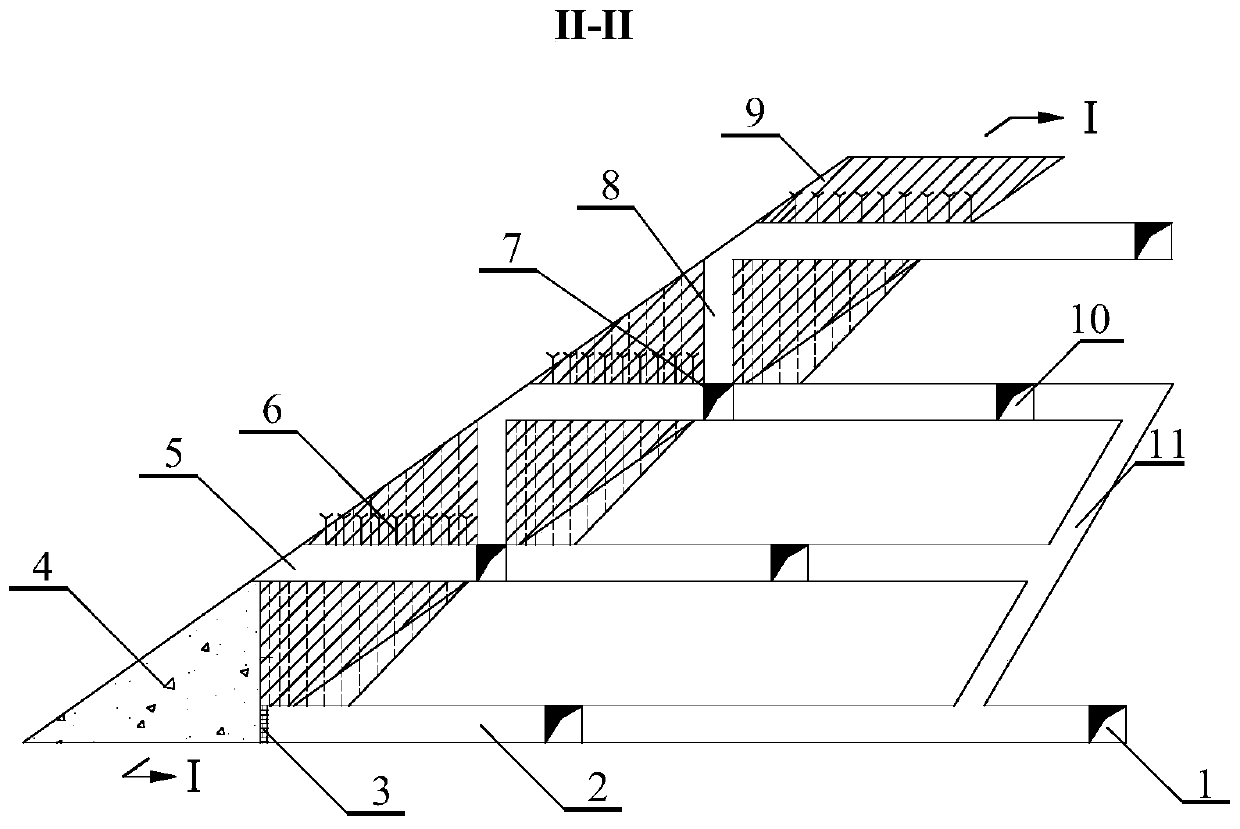

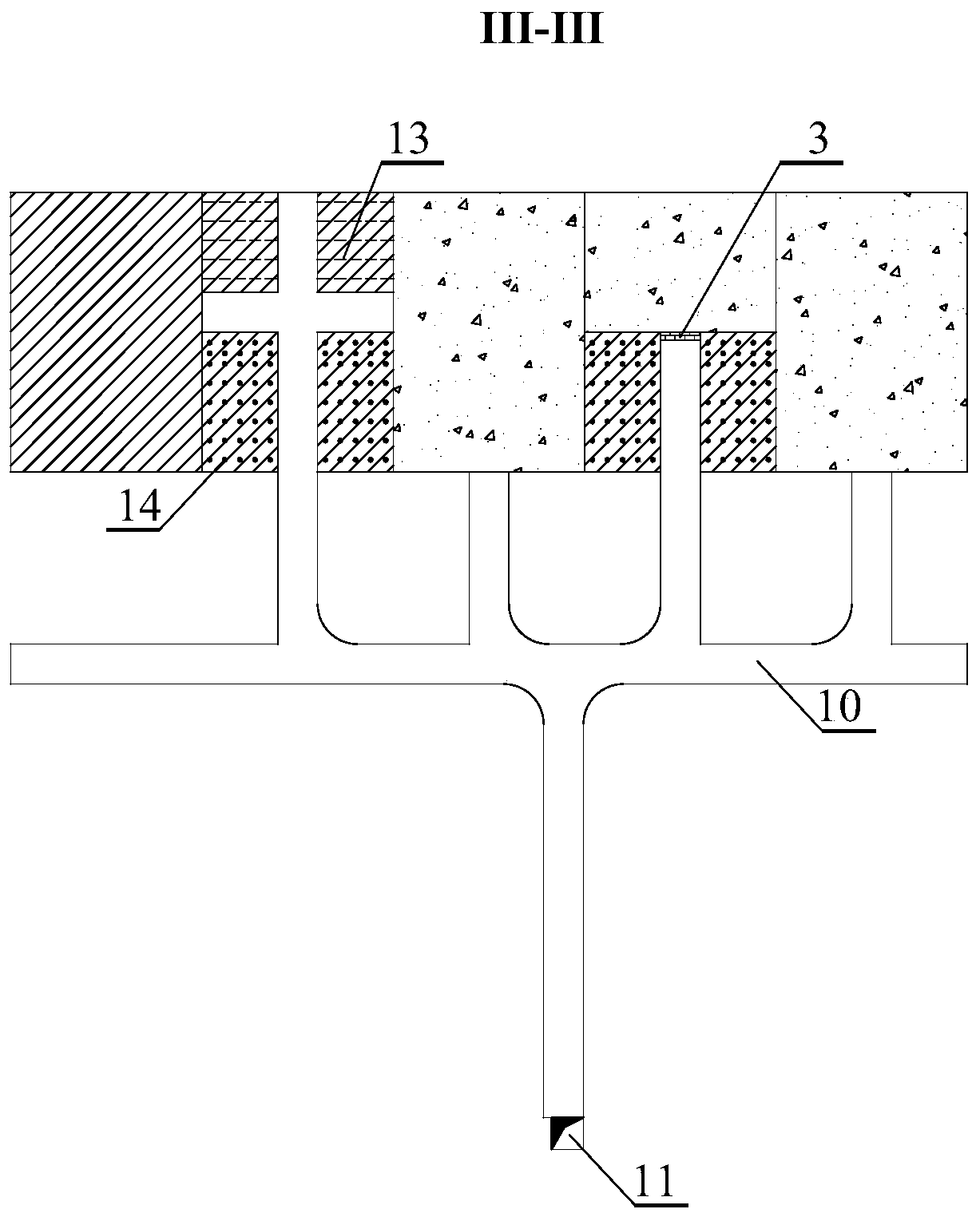

[0045] See figure 1 , figure 2 with image 3 , The figure is a schematic diagram of the internal structure of a mining area using a method of mining an inclined medium-thick metal ore body of the present invention. The specific mining implementation steps are as follows:

[0046] Step 1: Division of stope.

[0047] The ore body is divided into the stope along the direction of the ore body. The thickness of the stope is the thickness of the ore body, and the width of the stope is 10-15m. Because the ore body is inclinedly distributed, each stope in each section is close to the upper wall ore body and The footwall ore body is divided into upper triangle ore body and lower triangle ore body.

[0048] In the stope process, the stope is separated from one to the other. The upper triangle ore body is first recovered in the stope. After the empty area of the upper triangle is firmly filled, the lower triangle ore body is recovered. The height of the stage is 40-60m. Section, the sectio...

PUM

Login to View More

Login to View More Abstract

Description

Claims

Application Information

Login to View More

Login to View More - R&D

- Intellectual Property

- Life Sciences

- Materials

- Tech Scout

- Unparalleled Data Quality

- Higher Quality Content

- 60% Fewer Hallucinations

Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2025 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com