Preparation method of cadmium-doped molybdenum disulfide nano lubricating additive

A technology of lubricating additives and molybdenum disulfide, which is applied in the field of nanomaterials, can solve the problems of complex methods and high requirements for instruments and equipment, and achieve the effects of simple and easy-to-control processes, cost-effective input, and good tribological properties

- Summary

- Abstract

- Description

- Claims

- Application Information

AI Technical Summary

Problems solved by technology

Method used

Image

Examples

Embodiment 1

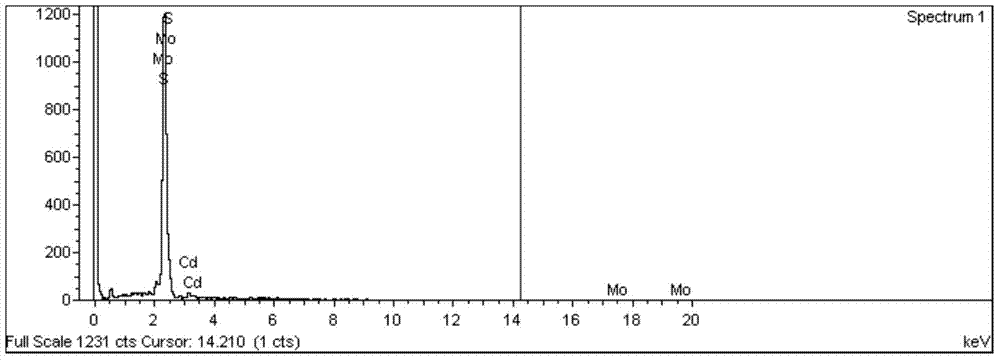

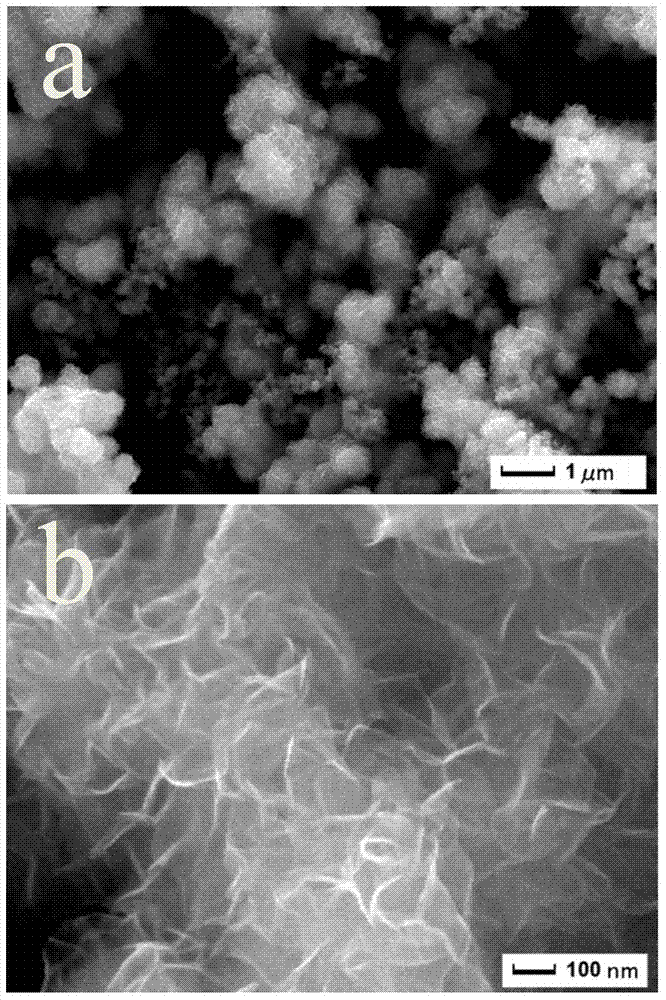

[0021] A Cd-doped MoS 2 The preparation method of nano lubricant additive, comprises the steps:

[0022] (1) Add 0.22g Na 2 MO 4 , 0.3g Na 2 S, 0.28g NH 2 OH HCl and 0.1g CdSO 4 Dissolve in 60mL of deionized water, dissolve completely, and set aside;

[0023] (2) Continue to stir for 30 minutes, then transfer the obtained mixed solution to a 100ml stainless steel reaction kettle, place it in a vacuum drying oven at 180°C for 24 hours, and cool to room temperature;

[0024] (3) After centrifugation, the reaction product was washed repeatedly with deionized water and absolute ethanol, and finally dried at 80°C for 10 h under vacuum to obtain a gray-black product powder, that is, Cd-doped MoS 2 Nano lubricant additive.

[0025] The reagents and processing conditions that embodiment 2-4 adopt are shown in Table 1:

[0026] Table 1

[0027]

Embodiment 5

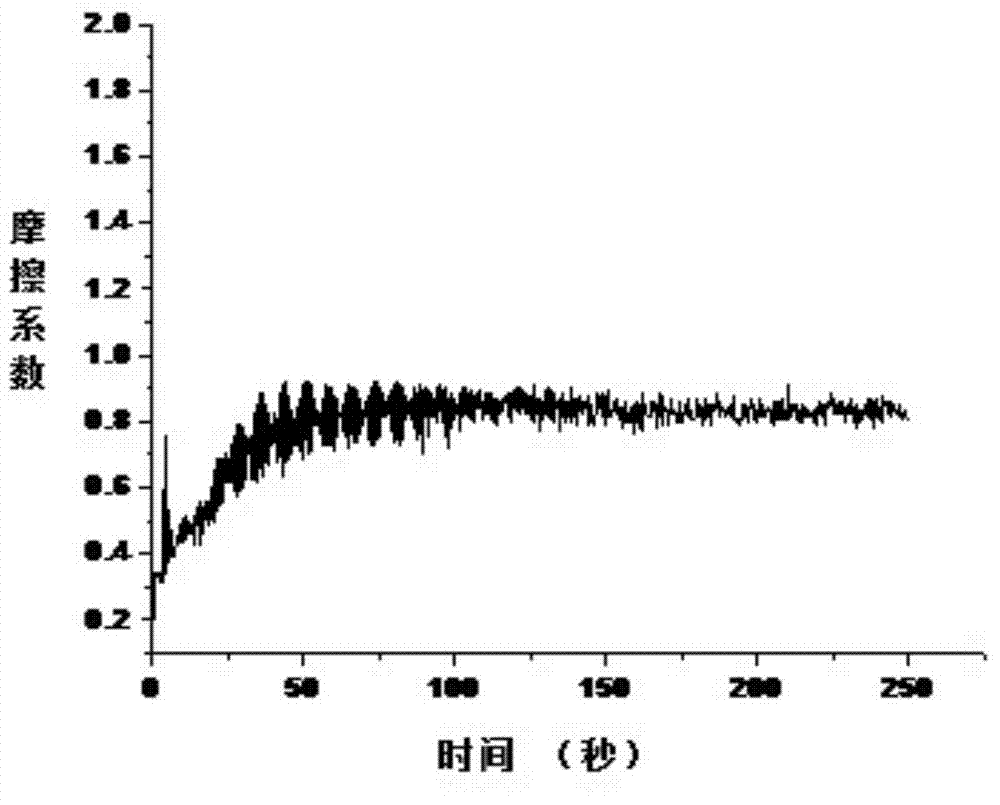

[0028] Example 5: Tribological test method: using an ultrasonic generator to dope the dispersant span 80 and the product Cd into MoS 2 The nanoflowers are uniformly dispersed in the base oil (paraffin), and prepared into a turbid liquid with a mass fraction of 1%-5%. The friction experiment of the oil sample is carried out on the CETR UMT-2 multifunctional friction and wear testing machine. The ball-disk contact is adopted, the rotation speed is 50-400rpm, the load is 10N-50N, and the experiment time is 30min. The type of stainless steel ball used in the experiment is 440-C (9Cr18), the diameter is 3mm, and the hardness is HRC62.

[0029] Cd-doped MoS obtained in Examples 1 to 4 2 The performance inspection parameters of nano-lubricating additives are shown in Table 2:

[0030] Table 2

[0031]

PUM

Login to View More

Login to View More Abstract

Description

Claims

Application Information

Login to View More

Login to View More - R&D

- Intellectual Property

- Life Sciences

- Materials

- Tech Scout

- Unparalleled Data Quality

- Higher Quality Content

- 60% Fewer Hallucinations

Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2025 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com