Dry film lubricant based on modified epoxy resin and preparation method thereof

A dry film lubricant, epoxy resin technology, applied in epoxy resin coatings, lubricating compositions, coatings, etc., can solve the problems of weather resistance, strengthening and toughening cannot be solved at the same time, and achieve low emission and comprehensive performance. Good, simple process to prepare the effect

- Summary

- Abstract

- Description

- Claims

- Application Information

AI Technical Summary

Problems solved by technology

Method used

Image

Examples

Embodiment 1

[0030] After adding 2 parts of silica nanoparticles with a particle size of 10-20nm to 0.5 part of γ-aminopropyltriethoxysilane, add 20 parts of absolute ethanol, and then place it on a magnetic stirrer at 800 rpm After stirring at the rotating speed for 20 minutes, it was added to 100 parts of E-06 water-based epoxy resin emulsion and magnetically stirred for 30 minutes. Then, 30 parts of polytetrafluoroethylene aqueous dispersion, 15 parts of molybdenum disulfide powder, 10 parts of chromium oxide powder with a particle size of 3 μm were added in sequence, and 2 parts of sodium dodecyl sulfonate were added dropwise. Stirring at a rotational speed of rev / min for 30 min to obtain a modified epoxy resin dry film lubricant.

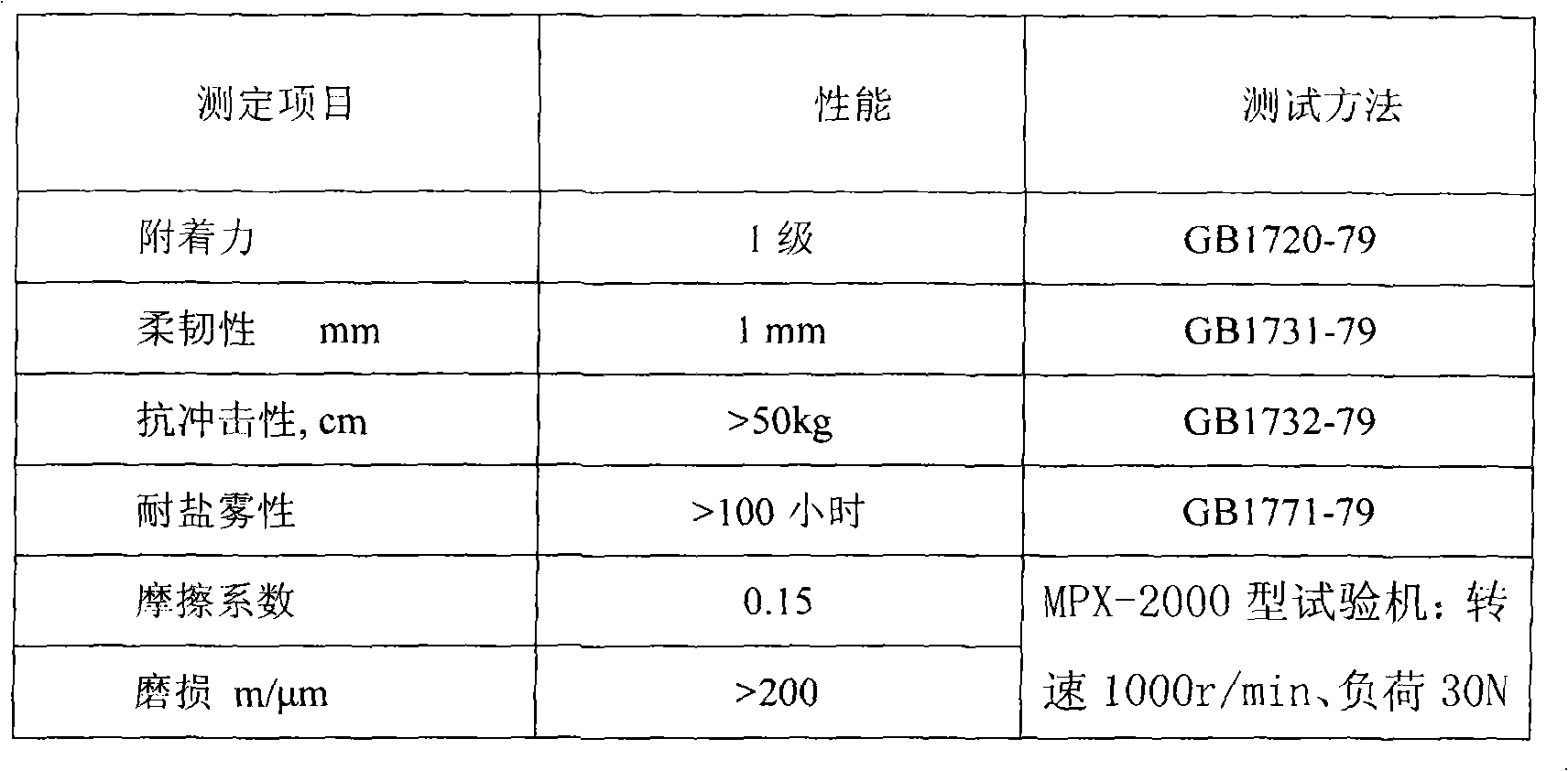

[0031] The properties of the above modified epoxy resin dry film lubricants were tested. Immerse the iron sheet that has been polished with sandpaper in the above water-based paint, slowly and vertically pull it out, let it stand for 5 minutes, put it in a...

Embodiment 2

[0035] After adding 0.4 part of γ-methacryloyloxypropyltrimethoxysilane dropwise to 3 parts of titanium dioxide nanoparticles with a particle size of 10-20nm, add 30 parts of absolute ethanol, and then place it on a magnetic stirrer at 800 rpm After stirring for 20 minutes at a rotational speed of / min, add it to 100 parts of E-033 waterborne epoxy resin emulsion, and stir magnetically for 30 minutes. Then, 40 parts of polytetrafluoroethylene aqueous dispersion, 20 parts of graphite powder, 10 parts of alumina powder with a particle size of 2 μm were added in sequence, 1 part of sodium dodecylbenzene sulfonate was added dropwise, and 10 parts of deionized water were added. After dilution, a mixing speed-adjusting disperser was used for stirring at a speed of 1500 rpm for 30 min to obtain a modified epoxy resin dry film lubricant.

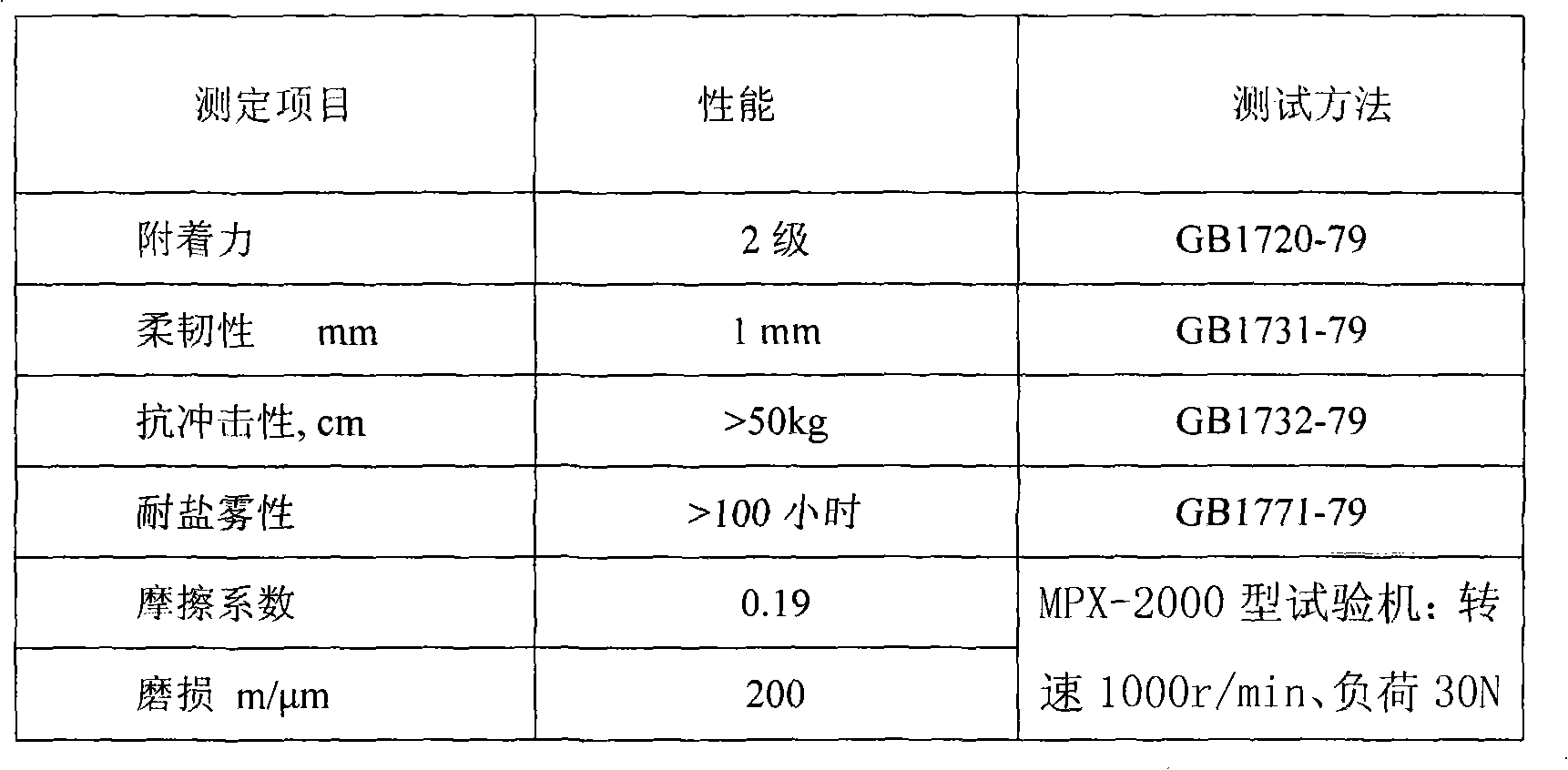

[0036] The properties of the above modified epoxy resin dry film lubricants were tested. Immerse the iron sheet that has been polished with sandpa...

Embodiment 3

[0040] After adding 5 parts of aluminum oxide nanoparticles with a particle size of 20-30nm to 0.2 part of γ-aminopropyltriethoxysilane, add 10 parts of absolute ethanol, and then place it on a magnetic stirrer at 800 rpm / After stirring for 20 minutes at a divided speed, add it to 100 parts of E-033 waterborne epoxy resin emulsion, and stir magnetically for 30 minutes. Then, 40 parts of molybdenum disulfide powder, 20 parts of graphite powder, 15 parts of chromium oxide powder with a particle size of 5 μm, 4 parts of sodium dodecyl sulfonate were added in sequence, and then 20 parts of deionized water were added for dilution. The speed disperser was stirred at 1500 rpm for 30 min to obtain the modified epoxy resin dry film lubricant.

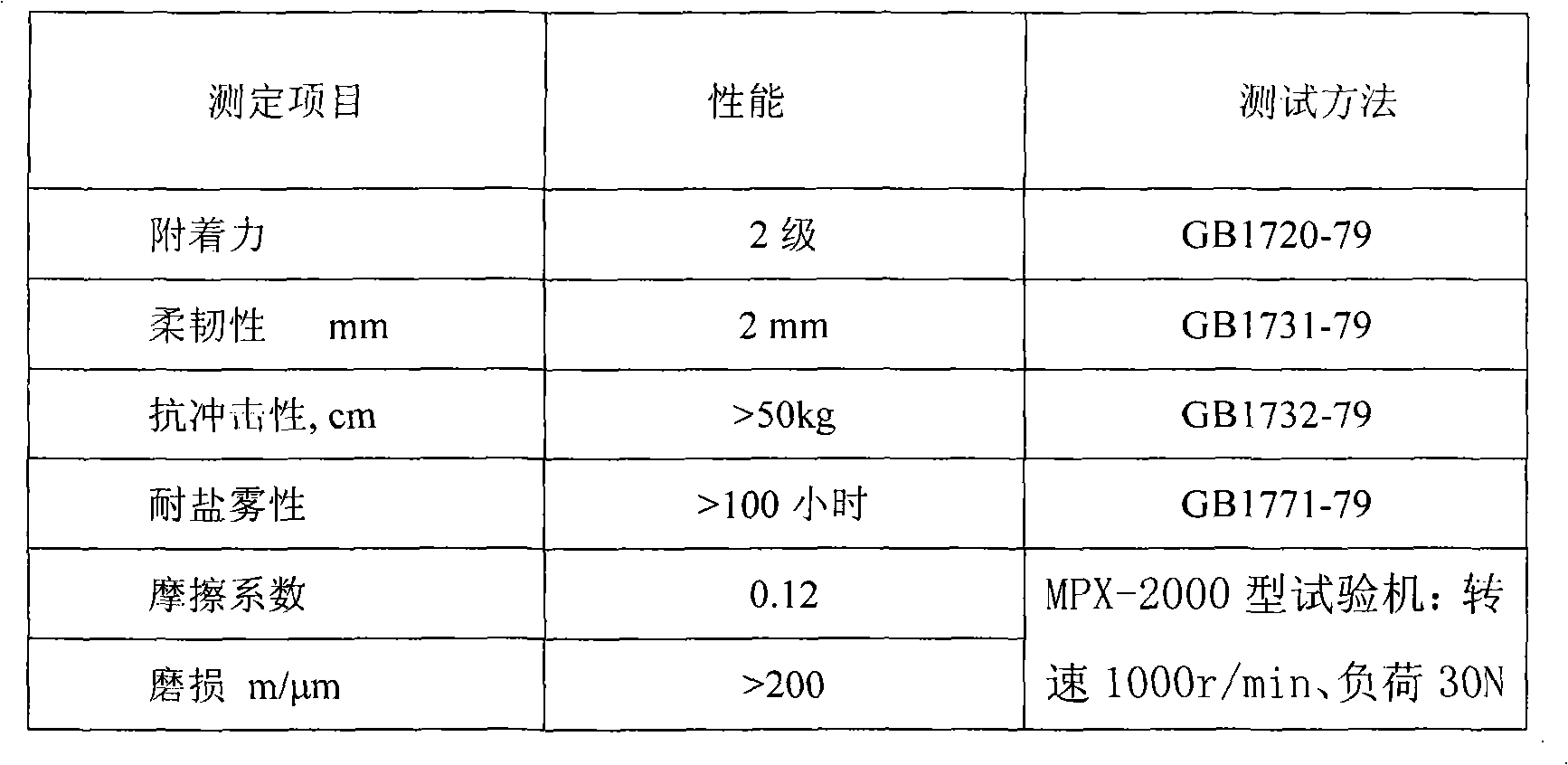

[0041] The properties of the above modified epoxy resin dry film lubricants were tested. Immerse the iron sheet that has been polished with sandpaper in the above water-based paint, slowly and vertically pull it out, let it stand for 5 minutes...

PUM

| Property | Measurement | Unit |

|---|---|---|

| particle size | aaaaa | aaaaa |

| particle diameter | aaaaa | aaaaa |

Abstract

Description

Claims

Application Information

Login to View More

Login to View More - R&D

- Intellectual Property

- Life Sciences

- Materials

- Tech Scout

- Unparalleled Data Quality

- Higher Quality Content

- 60% Fewer Hallucinations

Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2025 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com