Wear-resistant self-lubricating nylon compound material and method for preparing same

A nylon composite material, self-lubricating technology, applied in the field of polymer materials, can solve the problems of low physical and mechanical properties and cost performance, poor material processing performance, etc., and achieve excellent tribological properties, good dimensional stability and heat resistance, Simple and feasible synthesis method

- Summary

- Abstract

- Description

- Claims

- Application Information

AI Technical Summary

Problems solved by technology

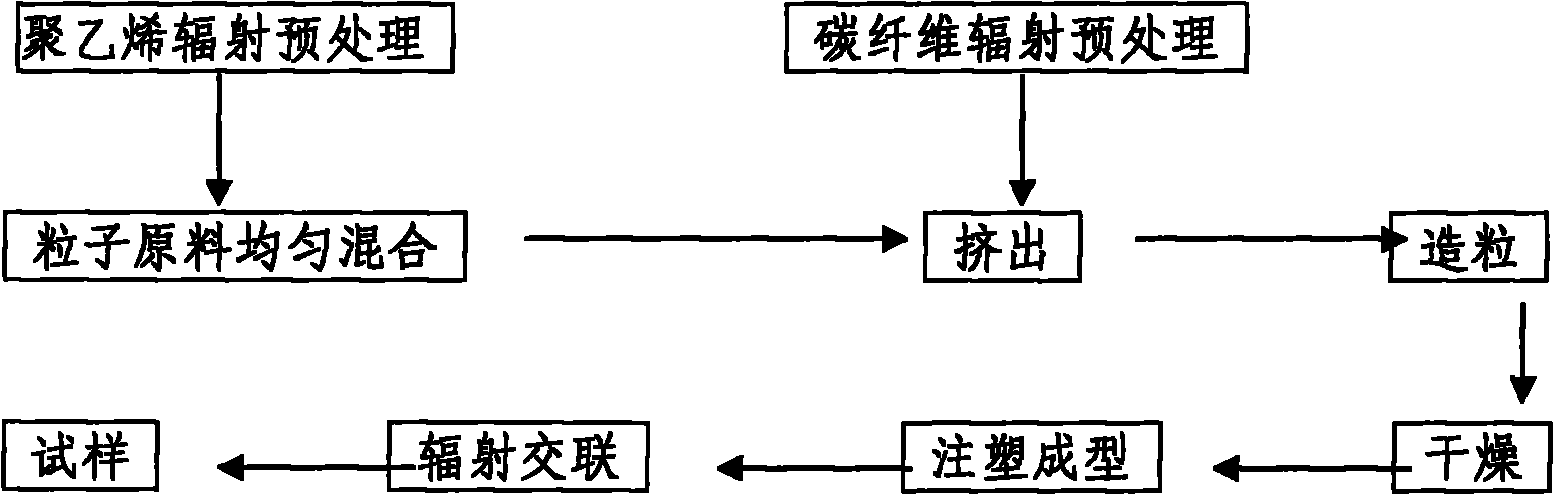

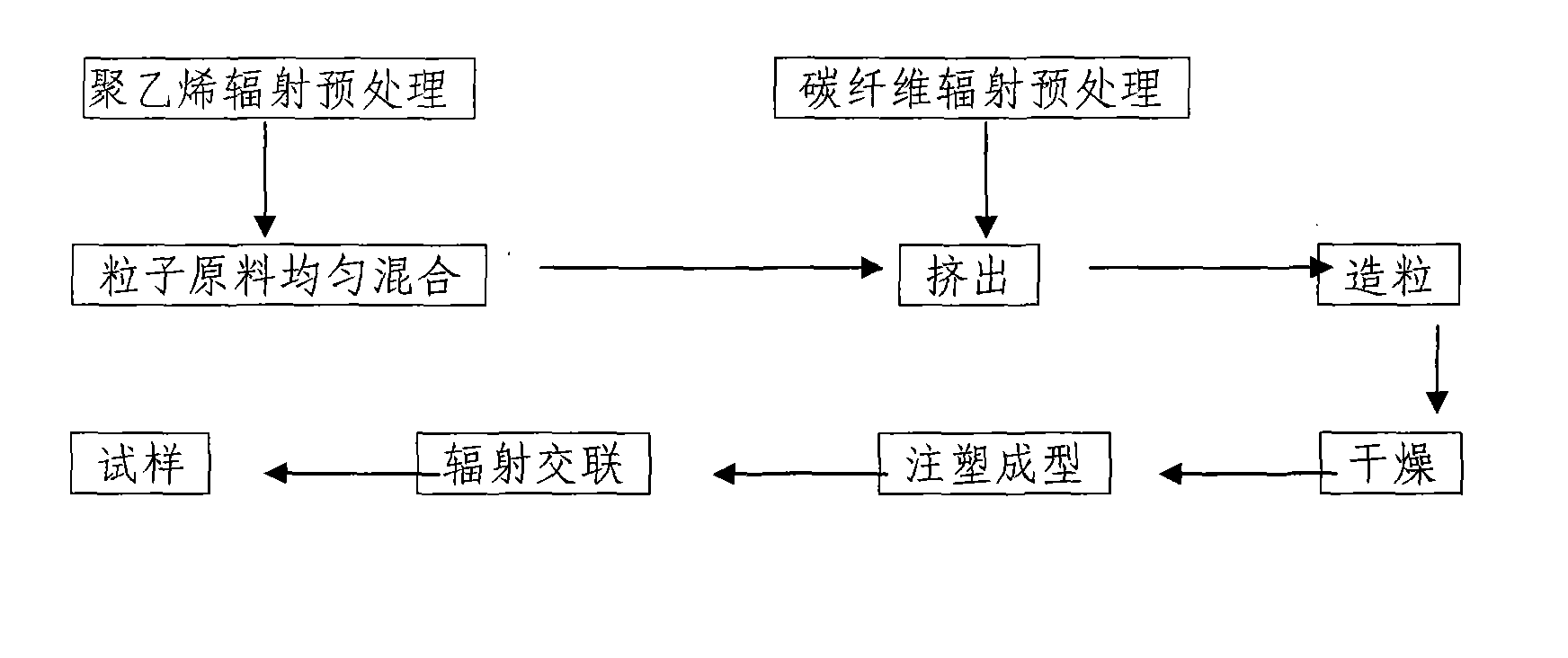

Method used

Image

Examples

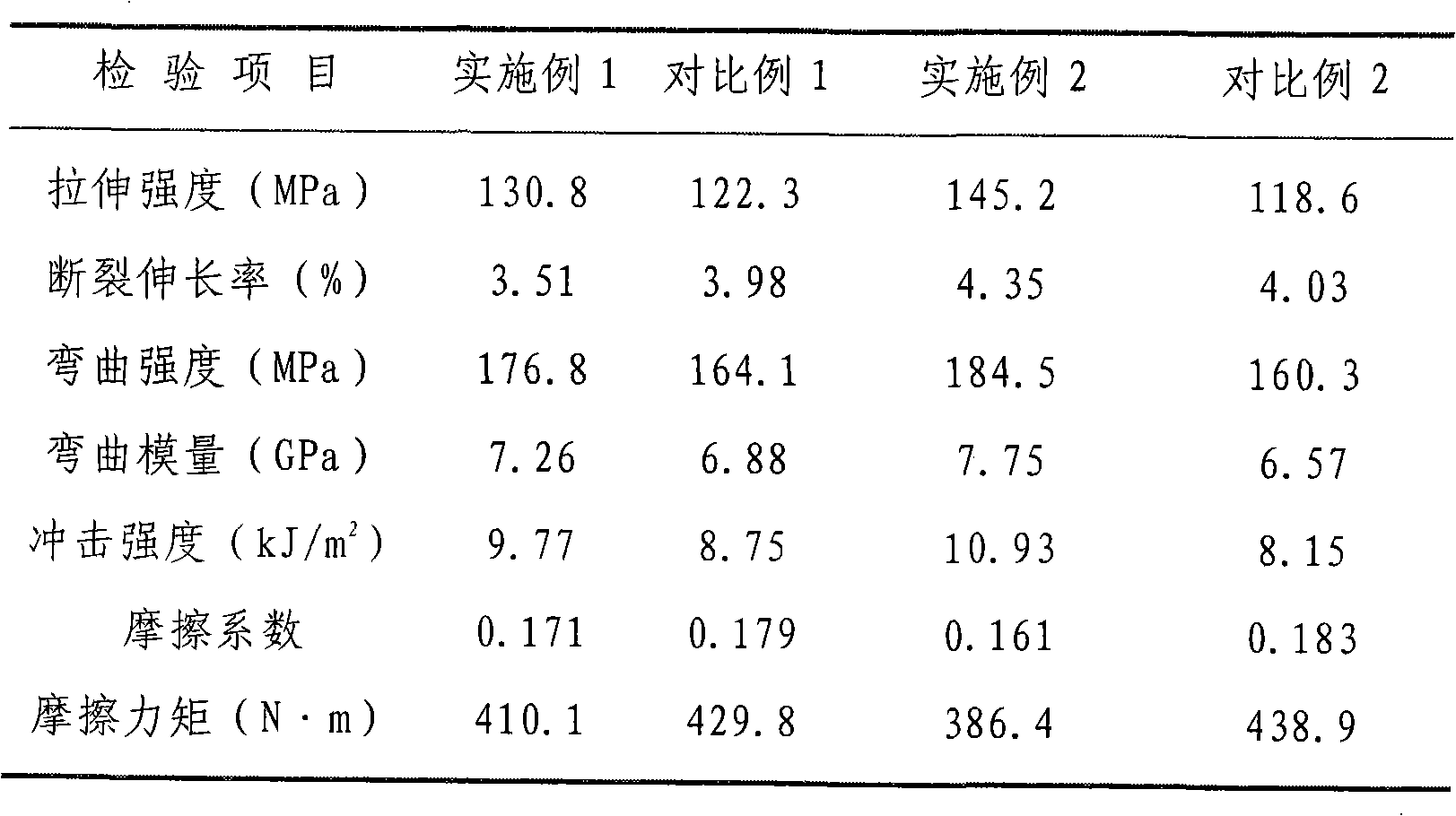

Embodiment 1

[0021] 1) Take the raw materials according to the weight ratio;

[0022] 2) Use the prepared 5 parts of high-density polyethylene and 10 parts of carbon fiber with 60 Coγ-rays or electron accelerators were irradiated at a dose rate of 10kGy / h for 4h and 3h respectively;

[0023] 3) With 100 parts of dried nylon 6 pellets and the high-density polyethylene obtained in step (2), add 8 parts of polytetrafluoroethylene (PTFE) superfine powder, 0.2 part of antioxidant: antioxidant 1010 and antioxidant 168 each accounted for 0.1 parts, 3 parts of compatibilizer CMG9805, 2 parts of radiation sensitizer: triallyl isocyanurate (TAIC), stirred and mixed evenly in a high-speed mixer;

[0024] 4) The material obtained in step (3) is fed into the twin-screw extruder through a feeder, and the carbon fiber obtained in step (2) is added to the side feeding port of the twin-screw extruder, and the twin-screw extruder The temperature of each section of the machine from the feeding port to the ...

Embodiment 2

[0028] 1) Take the raw materials according to the weight ratio;

[0029] 2) Use the prepared 10 parts of high-density polyethylene and 20 parts of carbon fiber with 60 Coγ-ray or electron accelerator 10kGy / h dose rate irradiation for 3h and 4h;

[0030] 3) 100 parts of high-density polyethylene obtained through drying processed nylon 6 pellets and step (2), then add 10 parts of polytetrafluoroethylene (PTFE) superfine powder, 0.2 part of antioxidant 1010, 2 parts Compatilizer CMG9805, 1 part of radiation sensitizer: triallyl isocyanurate (TAIC), stir and mix in a high-speed mixer;

[0031] 4) The material obtained in step (3) is fed into the twin-screw extruder through a feeder, and the carbon fiber obtained in step (2) is added to the side feeding port of the twin-screw extruder, and the twin-screw extruder The temperature of each section of the machine from the feeding port to the machine head is 200°C, 220°C, 230°C, 230°C, 230°C, 210°C, and the speed is 180r.p.m;

[0032...

PUM

| Property | Measurement | Unit |

|---|---|---|

| bending strength | aaaaa | aaaaa |

| flexural modulus | aaaaa | aaaaa |

| tensile strength | aaaaa | aaaaa |

Abstract

Description

Claims

Application Information

Login to View More

Login to View More - R&D

- Intellectual Property

- Life Sciences

- Materials

- Tech Scout

- Unparalleled Data Quality

- Higher Quality Content

- 60% Fewer Hallucinations

Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2025 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com