High-silicon aluminum alloy cylinder sleeve material and preparation method thereof

A high-silicon aluminum alloy and cylinder liner technology, which is applied in the field of high-silicon aluminum alloy cylinder liner materials and its preparation, can solve the problems of high material brittleness, high temperature of the alloy, low mechanical properties at room temperature, insufficient high temperature resistance and tribological properties of the alloy, etc. problems, to achieve good compatibility, high comprehensive mechanical properties, cylinder liner processing surface quality and superior effect of use

- Summary

- Abstract

- Description

- Claims

- Application Information

AI Technical Summary

Problems solved by technology

Method used

Image

Examples

preparation example Construction

[0089] Preparation method of high silicon aluminum alloy cylinder liner:

[0090] ① Composition design and precise batching: carry out precise batching according to the composition formula of the alloy of the present invention. In the batching method, the high melting point alloy elements such as silicon, iron, nickel, manganese, copper, vanadium, strontium, etc., are prepared by the method of master alloy, so that these high melting point alloy elements can be added to the low melting point aluminum , that is, in the form of charge of Al-40% Si, Al-30% Fe, Al-20% Ni, Al-50% Cu, Al-15% Mn, Al-15% V, Al-10% Sr master alloy ingredients. The melting point of magnesium is similar to that of aluminum, and the ingredients are prepared in the form of pure metal charge. After batching with the charge of master alloy, if the amount of aluminum is insufficient, it will be supplemented with the charge of pure aluminum.

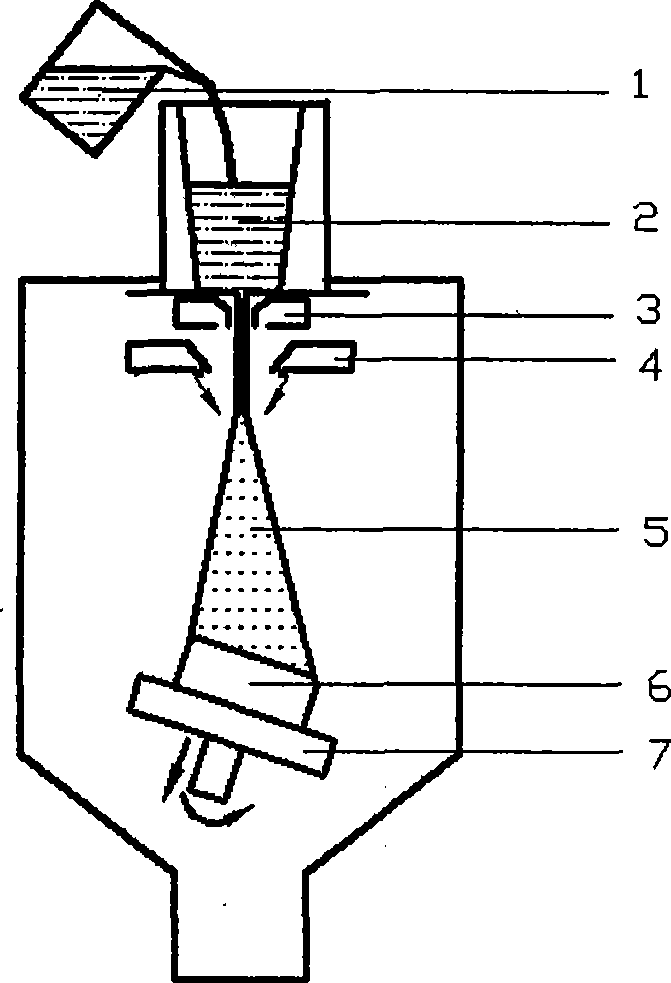

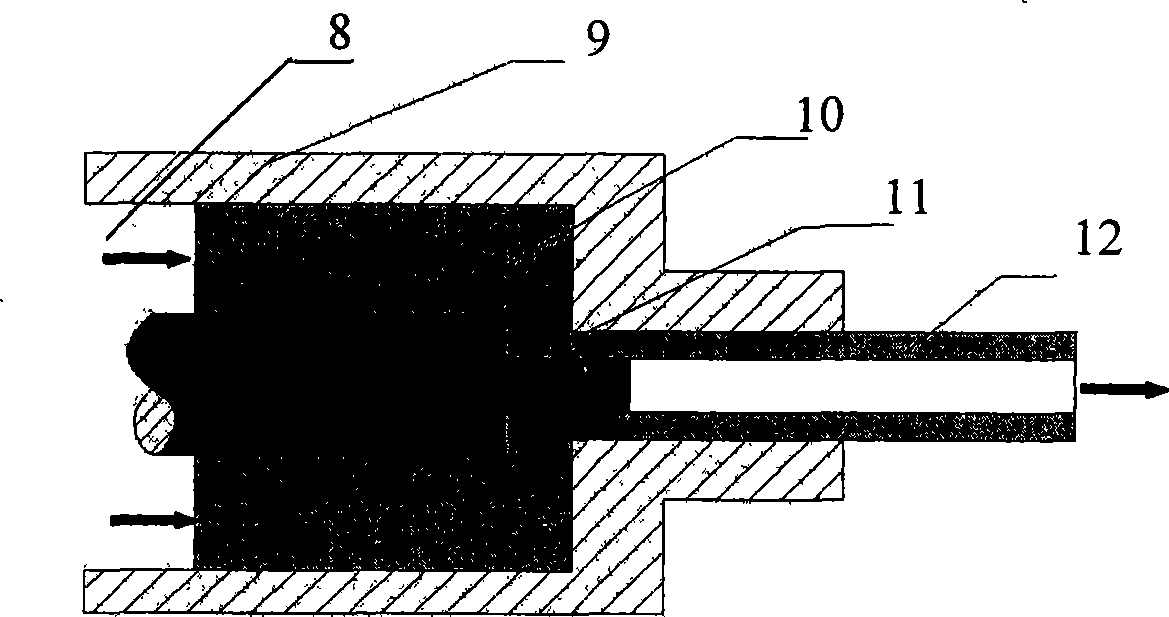

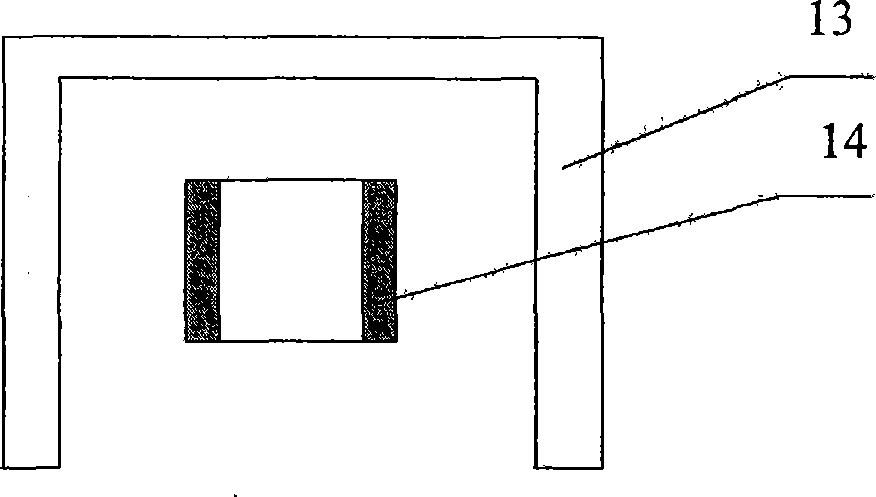

[0091] Such as Figure 4 Shown is the structure of the high-sil...

Embodiment 1、 Embodiment 2 and Embodiment 3

[0102] The material of the present invention and the product that adopt material of the present invention and above-mentioned preparation method to manufacture have the characteristics that:

[0103] Table 1 Chemical analysis of each embodiment (wt%)

[0104]

[0105]

[0106] Take Example 3 as an example to do batching calculation:

[0107] 1) the chemical composition of embodiment 3 is as follows:

[0108] Si: 20.52%; Fe: 5.11%; Ni: 1.88%; Cu: 2.52%; Mg: 0.73%; Mn: 1.22%; V: 0.35%; Sr: 0.1%;

[0109] 2) Calculate the ingredients according to 100 kg of charge in the furnace:

[0110] Then the amount of each alloy element is required to be:

[0111] Si: 20.52 kg; Fe: 5.11 kg; Ni: 1.88% kg; Cu: 2.52 kg; Mg: 0.73 kg; Mn: 1.22 kg; V: 0.35 kg; Sr: 0.1 kg;

[0112] Al: The balance is 100 kg - the total algebraic sum (32.43 kg) of the above alloying elements is 67.57 kg.

[0113] 3) Silicon, iron, nickel, manganese, copper, vanadium and strontium are added in the form of ...

Embodiment 4

[0142] Embodiment 3 material and the cylinder liner sample piece that adopt material of the present invention and preparation method to manufacture have the characteristics that:

[0143] Its thermophysical performance characteristics:

[0144] 1) thermal conductivity

[0145] At room temperature of 25°C, 85W / m / k; at high temperature of 250°C, 100W / m / k.

[0146] 2) Expansion coefficient

[0147] At room temperature 25°C, 15×10 -6 1 / °C; at a high temperature of 200°C, 16.85×10 -6 / °C.

[0148] At a high temperature of 300°C, 17.99×10 -6 1 / °C.

[0149] 3) Density

[0150] At room temperature 25°C, 2.86g / cm 3 .

[0151] It simulates the engine working conditions, and its tribological performance characteristics under the mechanical stress of fuel explosion pressure:

[0152] Table 3 The reciprocating friction and wear test data of simulated engine working conditions

[0153]

[0154] Note: 1) Calculated on the basis of the maximum burst pressure of 17MPa, loading pr...

PUM

Login to View More

Login to View More Abstract

Description

Claims

Application Information

Login to View More

Login to View More - R&D

- Intellectual Property

- Life Sciences

- Materials

- Tech Scout

- Unparalleled Data Quality

- Higher Quality Content

- 60% Fewer Hallucinations

Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2025 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com