Method for preparing ultra-lubricating compound carbon film material

A thin film material, composite carbon technology, applied in metal material coating process, superimposed layer plating, ion implantation plating and other directions, can solve the problems of rapid film peeling failure, high hardness, poor bonding strength, etc. Stability, high energy density, effect of increasing reactivity

- Summary

- Abstract

- Description

- Claims

- Application Information

AI Technical Summary

Problems solved by technology

Method used

Image

Examples

Embodiment 1

[0021] A. Sample pretreatment: The stainless steel substrate polished to the mirror surface was ultrasonically cleaned with absolute alcohol, distilled water, and acetone for 10 minutes, and then dried with nitrogen and placed in the deposition chamber. Pump the air pressure in the vacuum chamber to 6×10 -3 Below Pa, feed high-purity argon until the pressure is 3.0Pa. Turn on the pulse bias power supply, adjust the voltage value to -200V, and the duty cycle to 80%, and carry out argon plasma bombardment cleaning for 10 minutes.

[0022] B. Deposit silicon transition layer: adjust the flow rate of argon gas to maintain the chamber pressure at 2.5×10 -1 Pa, turn on the intermediate frequency sputtering power supply and the pulse bias power supply, adjust the sputtering current to 20A, the pulse bias voltage to -1000V, and the pulse duty cycle to 20%, and turn it off after the thickness of the transition layer reaches 500nm.

[0023] C. Deposit carbon layer: feed high-purity ar...

Embodiment 2

[0025] A. Sample pretreatment: The polished cemented carbide substrate was ultrasonically cleaned with absolute alcohol, distilled water, and acetone for 15 minutes, and then dried with nitrogen gas and placed in the deposition chamber. Pump the air pressure in the vacuum chamber to 6×10 -3 Below Pa, feed high-purity nitrogen until the pressure is 0.5Pa. Turn on the pulse bias power supply, adjust the voltage value to -1200V, and make the duty cycle 20%, and carry out argon plasma bombardment cleaning for 20 minutes.

[0026] B. Deposit silicon transition layer: adjust the flow rate of argon gas to maintain the chamber pressure at 1.0Pa, turn on the intermediate frequency sputtering power supply and pulse bias power supply, adjust the sputtering current to 3A, the pulse bias voltage to -100V, and the pulse duty cycle 50%, and turn off when the thickness of the transition layer reaches 50nm.

[0027] C. Deposit carbon layer: feed high-purity argon and methane mixed gas to mai...

Embodiment 3

[0029] A. Sample pretreatment: The steel ball substrate polished to the mirror surface was ultrasonically cleaned with absolute alcohol, distilled water, and acetone for 30 minutes, and then dried with nitrogen gas and placed in the deposition chamber. Pump the air pressure in the vacuum chamber to 6×10 -3 Below Pa, feed high-purity argon until the pressure is 1.0Pa. Turn on the pulse bias power supply, adjust the voltage value to -1000V, and the duty cycle to 60%, and perform argon plasma bombardment cleaning for 30 minutes.

[0030] B. Deposit silicon transition layer: adjust the flow rate of argon to maintain the chamber pressure at 5.5×10 -1 Pa, turn on the intermediate frequency sputtering power supply and the pulse bias power supply, adjust the sputtering current to 8A, the pulse bias voltage to -400V, and the pulse duty cycle to 80%, and turn it off after the thickness of the transition layer reaches 300nm.

[0031] C. Depositing carbon layer: Inject a mixed gas of hi...

PUM

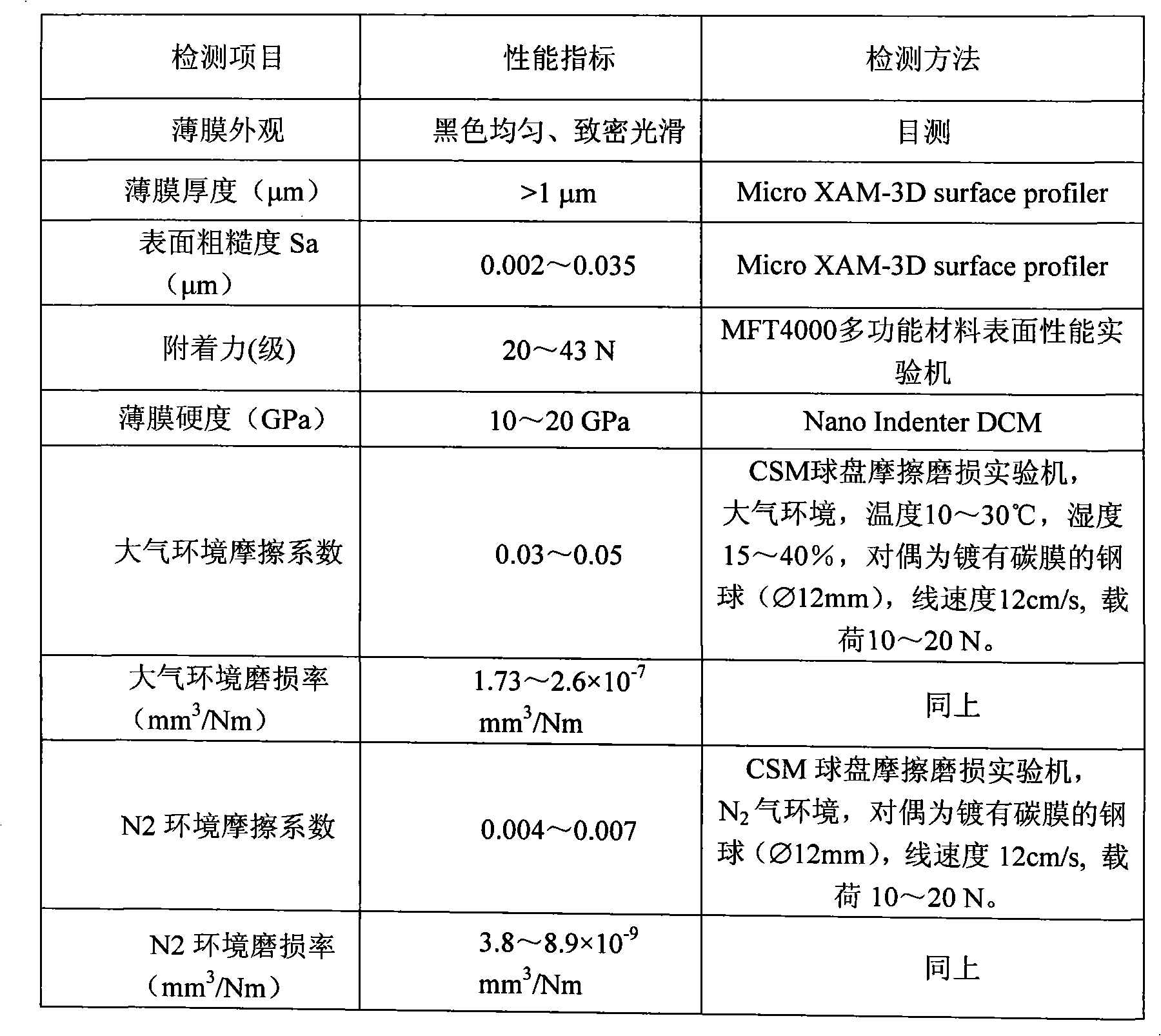

| Property | Measurement | Unit |

|---|---|---|

| hardness | aaaaa | aaaaa |

| wear rate | aaaaa | aaaaa |

| friction coefficient | aaaaa | aaaaa |

Abstract

Description

Claims

Application Information

Login to View More

Login to View More - R&D

- Intellectual Property

- Life Sciences

- Materials

- Tech Scout

- Unparalleled Data Quality

- Higher Quality Content

- 60% Fewer Hallucinations

Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2025 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com