Nanoparticle jet flow minimum quantity lubrication grinding lubricant supply system

A supply system, micro-lubrication technology, applied in grinding/polishing equipment, grinding/polishing safety devices, metal processing equipment, etc., can solve the problem of limited cooling effect of high-pressure air flow, inability to meet high grinding zone temperature enhanced heat transfer, Eliminate problems such as reduced processing quality and grinding wheel life, and achieve excellent flow properties, increased thermal conductivity, and improved lubricating properties

- Summary

- Abstract

- Description

- Claims

- Application Information

AI Technical Summary

Problems solved by technology

Method used

Image

Examples

Embodiment Construction

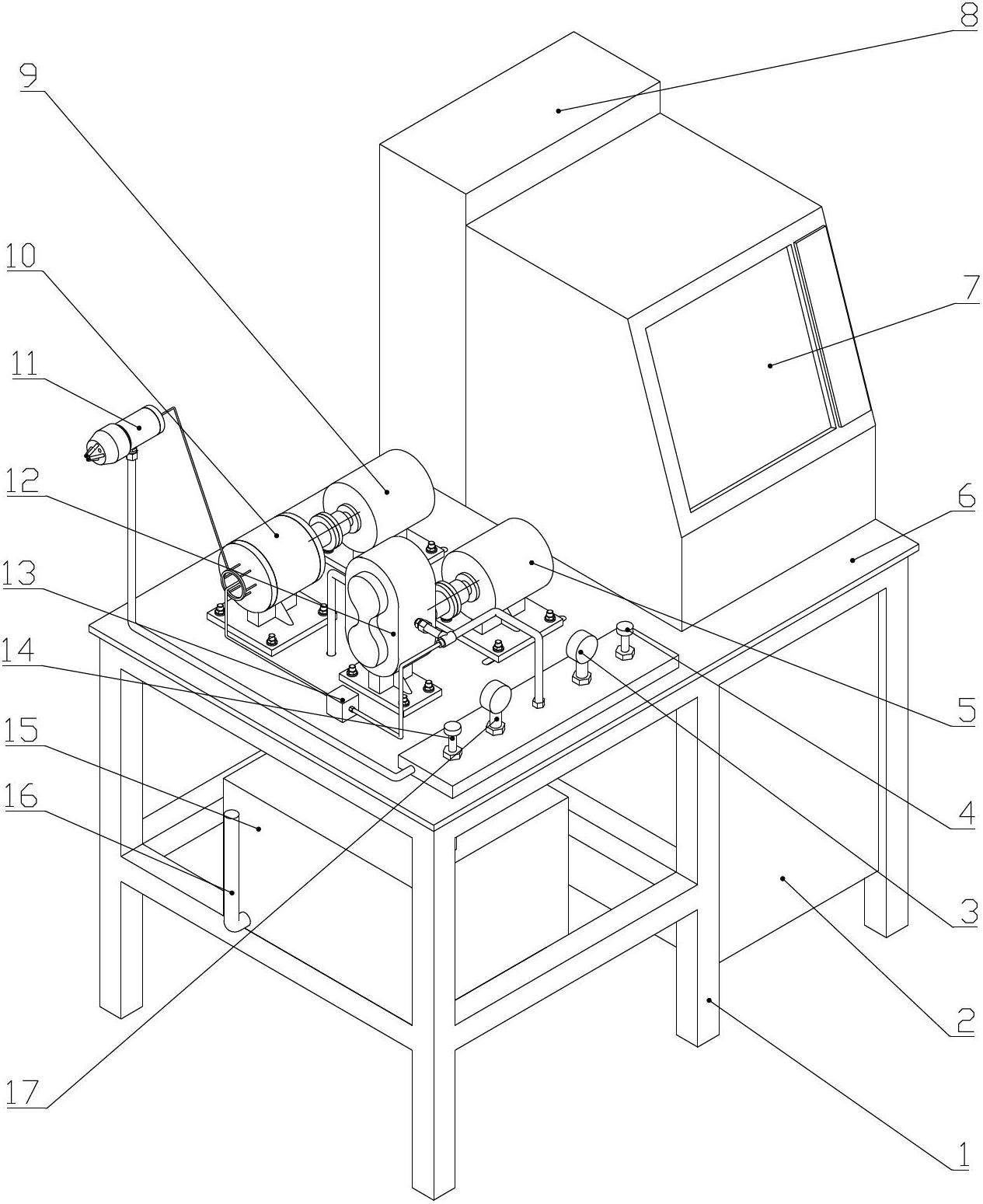

[0032] The present invention will be further described below in conjunction with the accompanying drawings and embodiments.

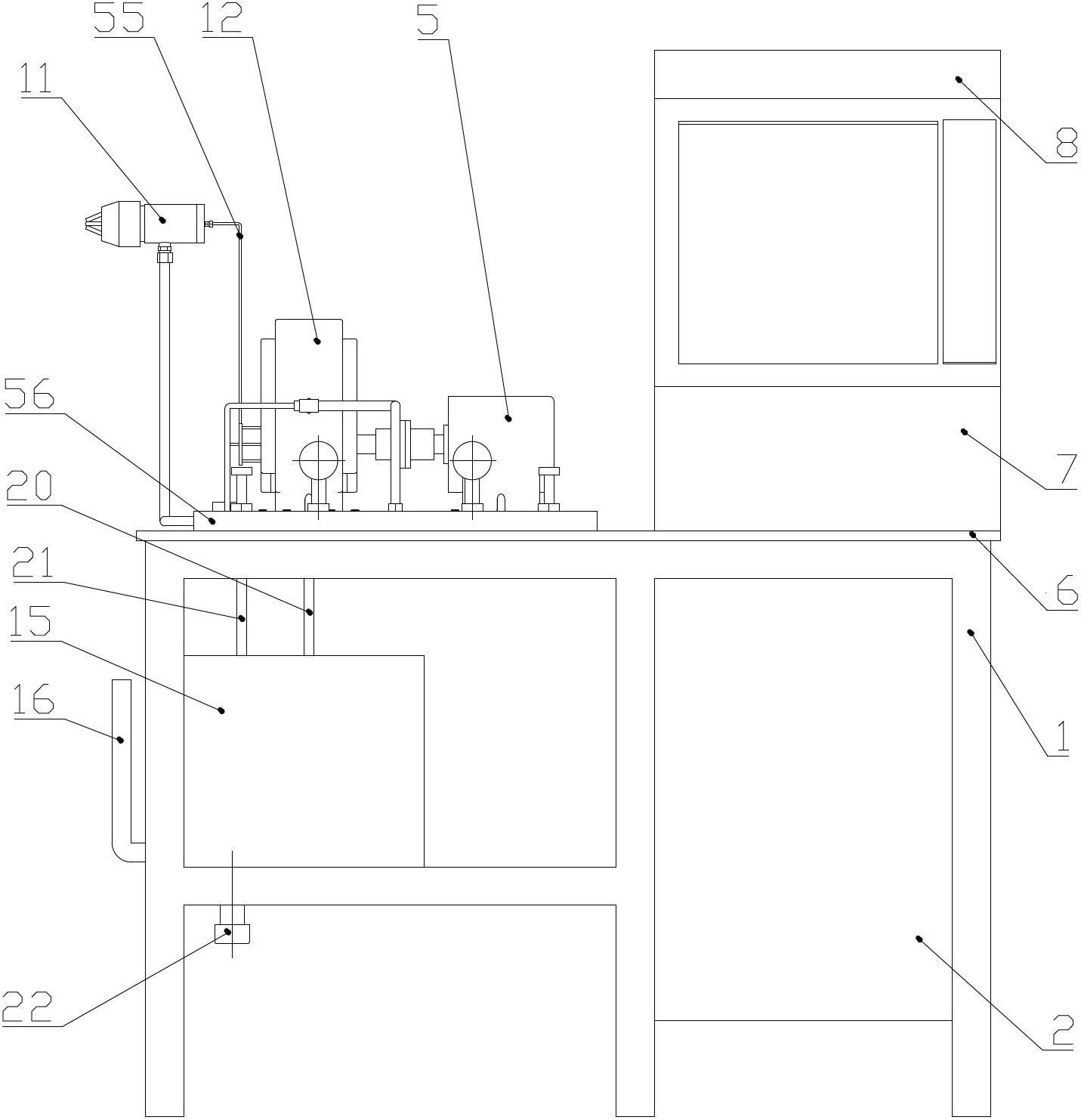

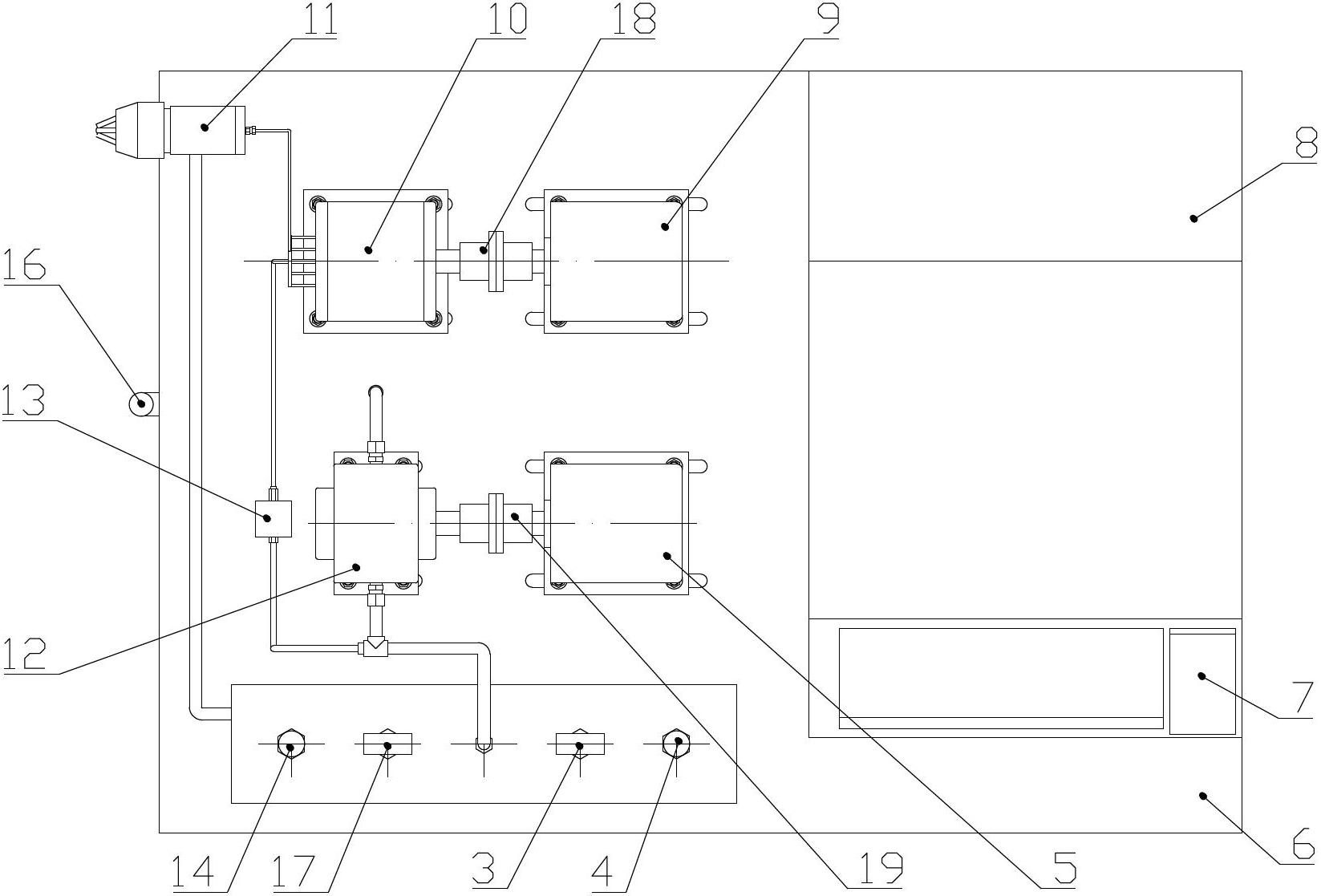

[0033] figure 1 Among them, the nano particle jet microlubrication grinding lubricant supply system of the present invention is mainly composed of four parts, namely the equipment body, the compressed air supply system, the lubricant supply system and the servo drive system, and the bed 1 of the equipment body is equipped with Air compressor 2 and oil tank 15, valve plate 56 installed on workbench 6 of bed 1, industrial computer 7, servo driver 8, servo motor I5, servo motor II9, oil discharge unit 10, gear pump 12 and filter I13 , wherein a pressure gauge I3, a safety valve 4, a relief valve 14 and a pressure gauge II17 are installed on the valve inserting plate 56, and a nozzle 11 is installed at the end of the compressed air pipeline drawn from the inserting valve plate 56.

[0034] combine figure 1 , figure 2 It can be seen that the oil tank 15 ...

PUM

Login to View More

Login to View More Abstract

Description

Claims

Application Information

Login to View More

Login to View More - R&D

- Intellectual Property

- Life Sciences

- Materials

- Tech Scout

- Unparalleled Data Quality

- Higher Quality Content

- 60% Fewer Hallucinations

Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2025 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com