Frost prevention nozzle used for low-temperature minimal quantity lubrication cutting

A kind of micro-lubrication and nozzle technology, which is applied in the direction of injection device, liquid injection device, etc., can solve the problems of loud noise, the airflow at the outlet is not properly configured, and restrict the promotion and application of low-temperature micro-lubrication technology. The effect of reducing cooling loss

- Summary

- Abstract

- Description

- Claims

- Application Information

AI Technical Summary

Problems solved by technology

Method used

Image

Examples

Embodiment Construction

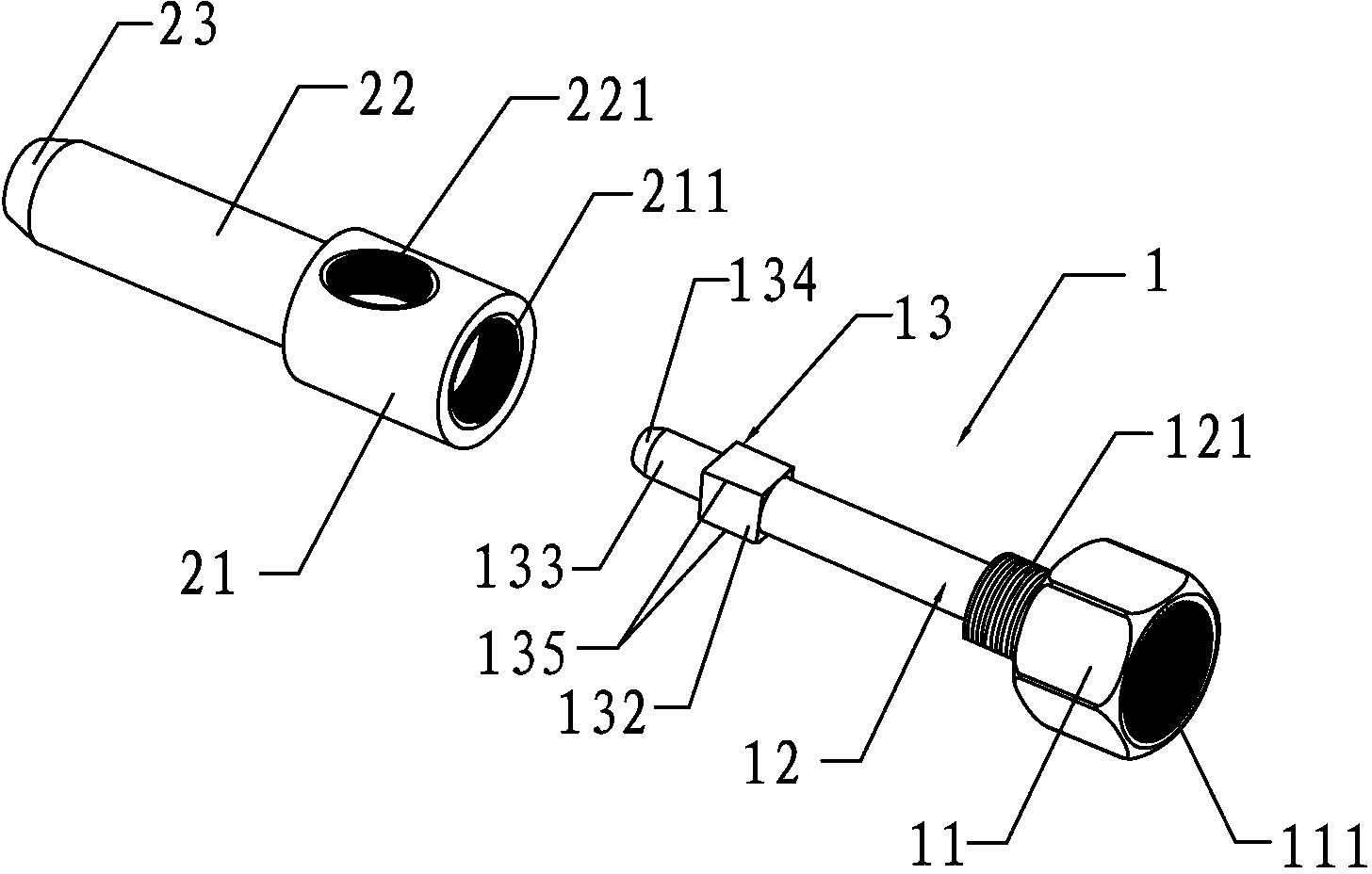

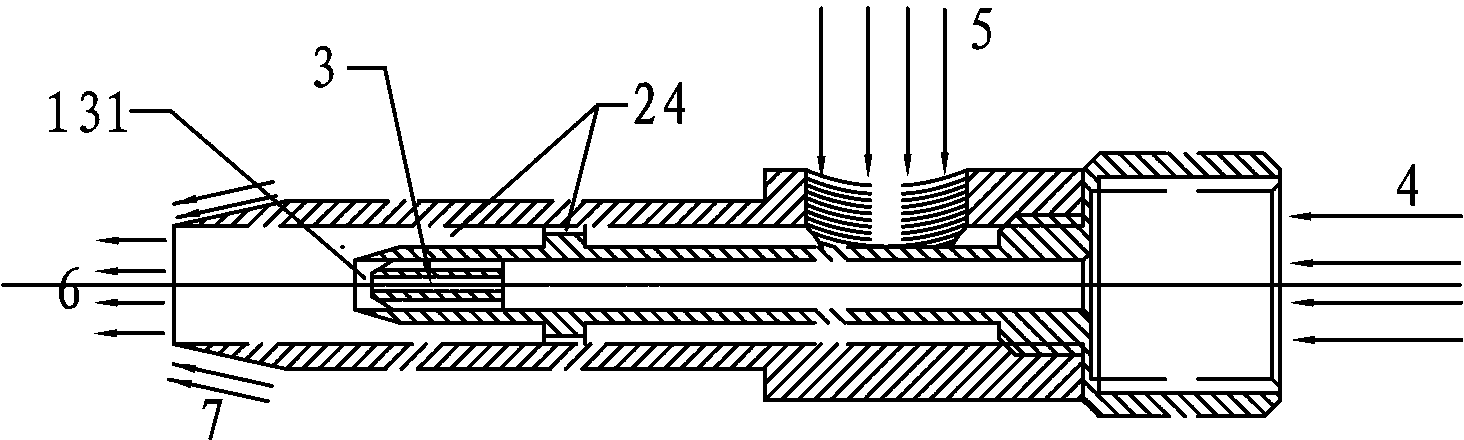

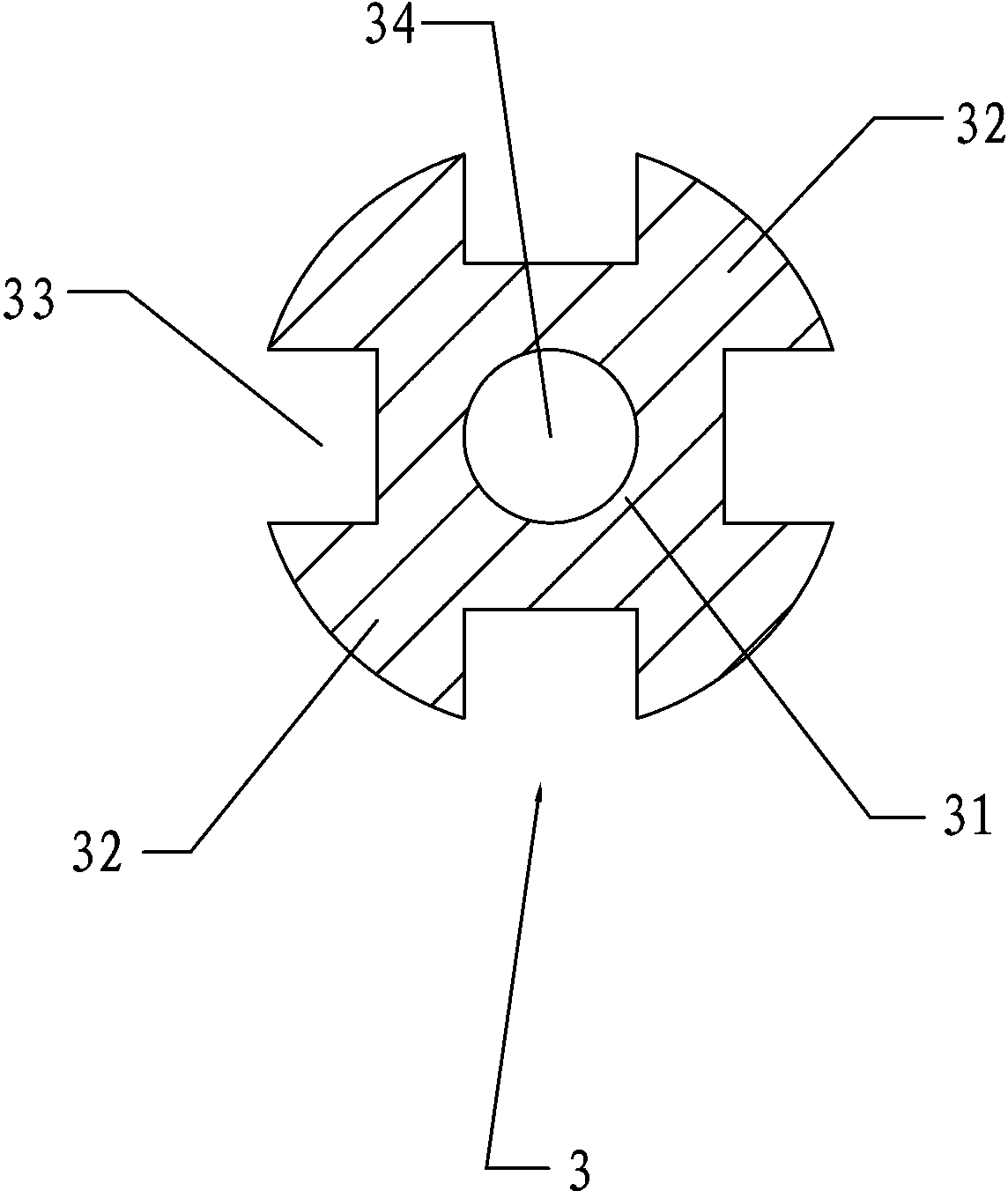

[0031] The present invention will be further described in conjunction with following embodiment and accompanying drawing, as Figure 1 to Figure 4 shown.

[0032] An anti-frost nozzle for low-temperature minimal-quantity lubrication cutting in this embodiment includes a nozzle body 1 and a nozzle sleeve 2, the nozzle body 1 includes a fixed part 11, a rod part 12 and a spray part 13 connected in sequence, and the fixed part 11 A first threaded interface 111 is provided, an external thread 121 connected to the nozzle casing 2 is provided at the bottom of the rod part 12, and a spray hole 131 is opened on the top of the spray part 13, and a gas flow divider 3 is arranged in the spray hole 131; The nozzle sleeve 2 includes an integrally formed sleeve bottom 21, a sleeve middle 22, and a sleeve guide cone 23. The sleeve bottom 21 is provided with a second threaded interface 211 used in conjunction with the external thread 121. The nozzle body 1 Screwed with the nozzle sleeve 2 to...

PUM

Login to View More

Login to View More Abstract

Description

Claims

Application Information

Login to View More

Login to View More - R&D

- Intellectual Property

- Life Sciences

- Materials

- Tech Scout

- Unparalleled Data Quality

- Higher Quality Content

- 60% Fewer Hallucinations

Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2025 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com