A falling film heat exchanger with spiral arrangement of pipes

A falling film heat exchanger technology, applied in evaporators/condensers, lighting and heating equipment, refrigeration components, etc., can solve the problem of low space utilization of heat exchangers, heat exchange time of shell-side fluid and tube-side fluid Short and other problems, to achieve the effect of improving flexibility, reducing possibility, and high heat transfer density

- Summary

- Abstract

- Description

- Claims

- Application Information

AI Technical Summary

Problems solved by technology

Method used

Image

Examples

Embodiment 1

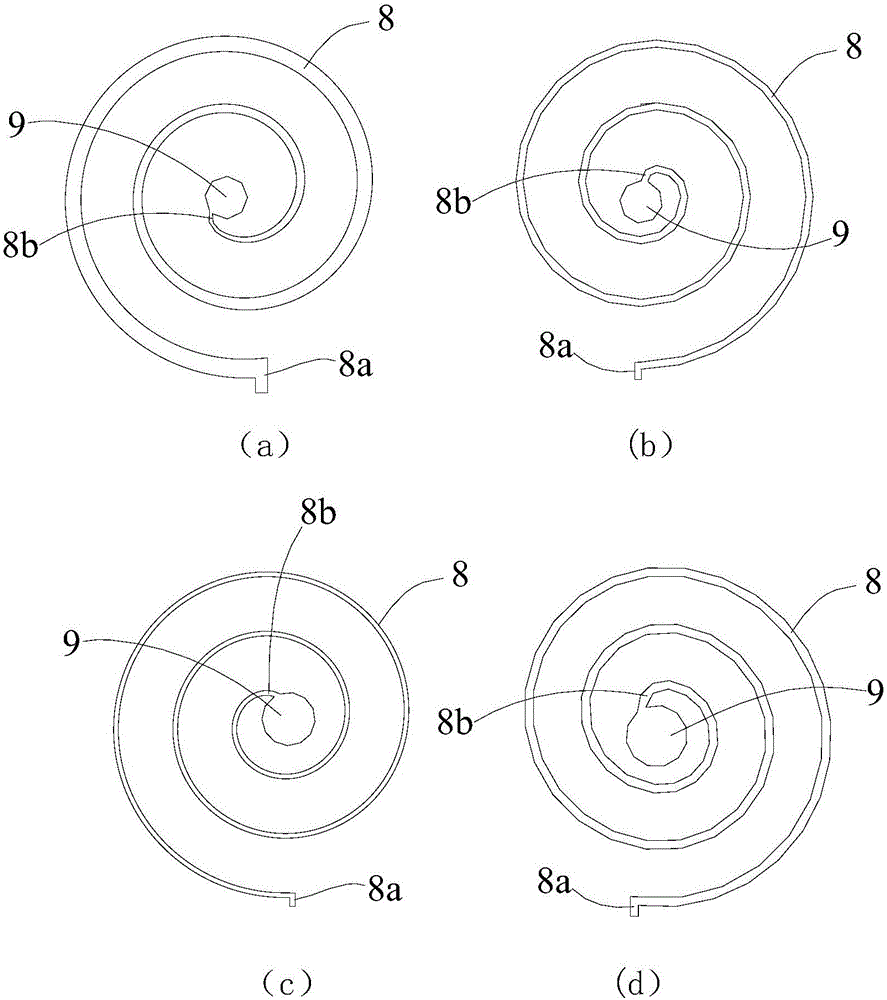

[0043] like Figure 7 , 8 , 9 This example is suitable for evaporators in the field of refrigeration and air conditioning, fluid A is selected as the refrigerant, and fluid B (air) is selected as the secondary refrigerant. Fluid A is in a gas-liquid mixed state before entering the heat exchanger. After entering the heat exchanger from the fluid A inlet 2 at the top, the fluid A passes through the fluid A distributor 7 and evenly sprays to the outer wall of the spiral pipe 8. The outer wall surface of the spiral pipe 8 flows downward in a film shape, because the temperature of the refrigerant A (fluid A and refrigerant A refer to the same substance in this embodiment 1) is lower than that of the refrigerant B (the fluid B and the refrigerant A in this embodiment 1 Refrigerant B refers to the same substance), so the heat is transferred from the brine to the refrigerant, and the temperature of the brine decreases. The generated refrigerant vapor is led out from the gaseous flui...

Embodiment 2

[0049] This example is suitable for the concentration and purification of substances in the chemical and pharmaceutical fields. Set fluid A as the liquid to be concentrated. At this time, the concentration of a certain substance a in fluid A is relatively low, and the channel of fluid B is passed through a hot fluid with a higher temperature (high temperature steam). The heat exchange process between the two is similar to that in Example 1. After successively passing through each layer of heat exchange pipes, the moisture in fluid A will be partially vaporized due to the heat obtained. As the heat exchange progresses, the concentration of substance a in fluid A increases, and the moisture or liquid impurities become less. Therefore, a fluid A containing a higher concentration of a is produced at the bottom of the heat exchanger, and when the required requirements are met, the heat exchanger can be separated from the bottom.

[0050] There is another variant of this embodiment...

Embodiment 3

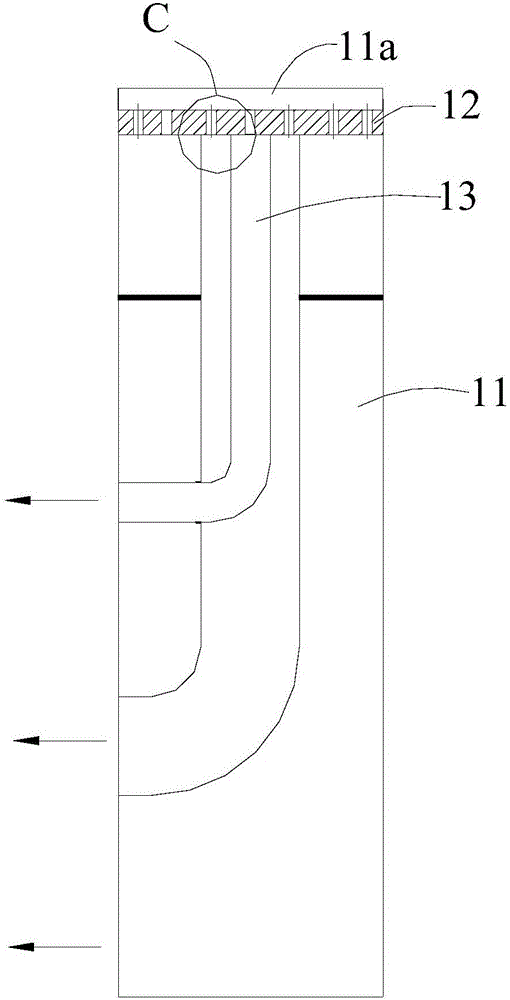

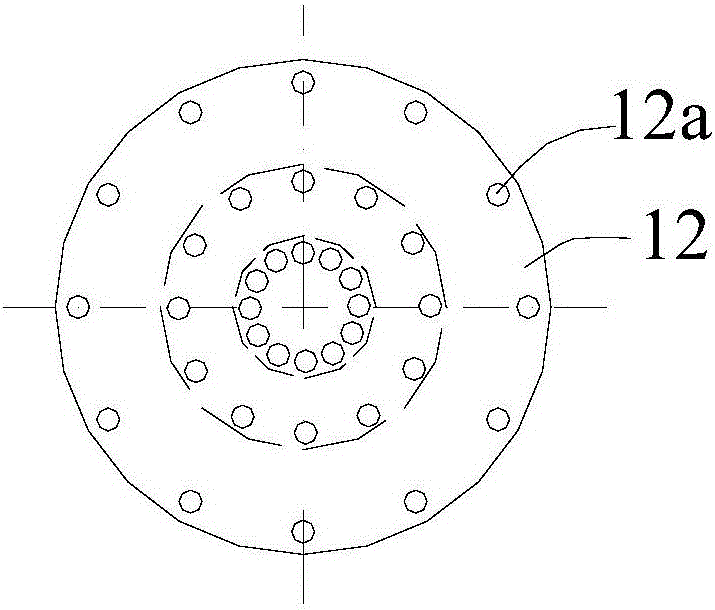

[0058] like figure 2 and image 3 Another implementation form of the present invention includes a fluid B distribution chamber 11, a fluid inlet 11a is provided on the fluid B distribution chamber 11, a fluid B distributor 12 is arranged in the fluid B distribution chamber 11, and a A fluid B distribution conduit 13 between the fluid B distributor 12 and the fluid B inlet 5 . There are two fluid B distribution pipes 13, the inlet ends of multiple fluid B distribution pipes 13 are nested with each other, and the outlet ends of the inner fluid B distribution pipes are connected to the fluid B inlets through the outer fluid B distribution pipes.

[0059] This embodiment is suitable for the heat exchange between two liquid working fluids and the required heat transfer is very small. Since the heat transfer is very small, it is assumed that the number of layers of spiral pipes in the main body of the evaporator is small ( This embodiment takes 3 layers as an example), the workin...

PUM

Login to View More

Login to View More Abstract

Description

Claims

Application Information

Login to View More

Login to View More - R&D

- Intellectual Property

- Life Sciences

- Materials

- Tech Scout

- Unparalleled Data Quality

- Higher Quality Content

- 60% Fewer Hallucinations

Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2025 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com