Oil cooling structure of permanent magnet synchronous motor

A permanent magnet synchronous motor and oil cooling technology, which is applied in the direction of electrical components, electromechanical devices, electric components, etc., can solve problems such as low cooling efficiency, achieve smooth oil output, good cooling effect, and obvious improvement

- Summary

- Abstract

- Description

- Claims

- Application Information

AI Technical Summary

Problems solved by technology

Method used

Image

Examples

Embodiment Construction

[0024] Preferred embodiment of the present invention:

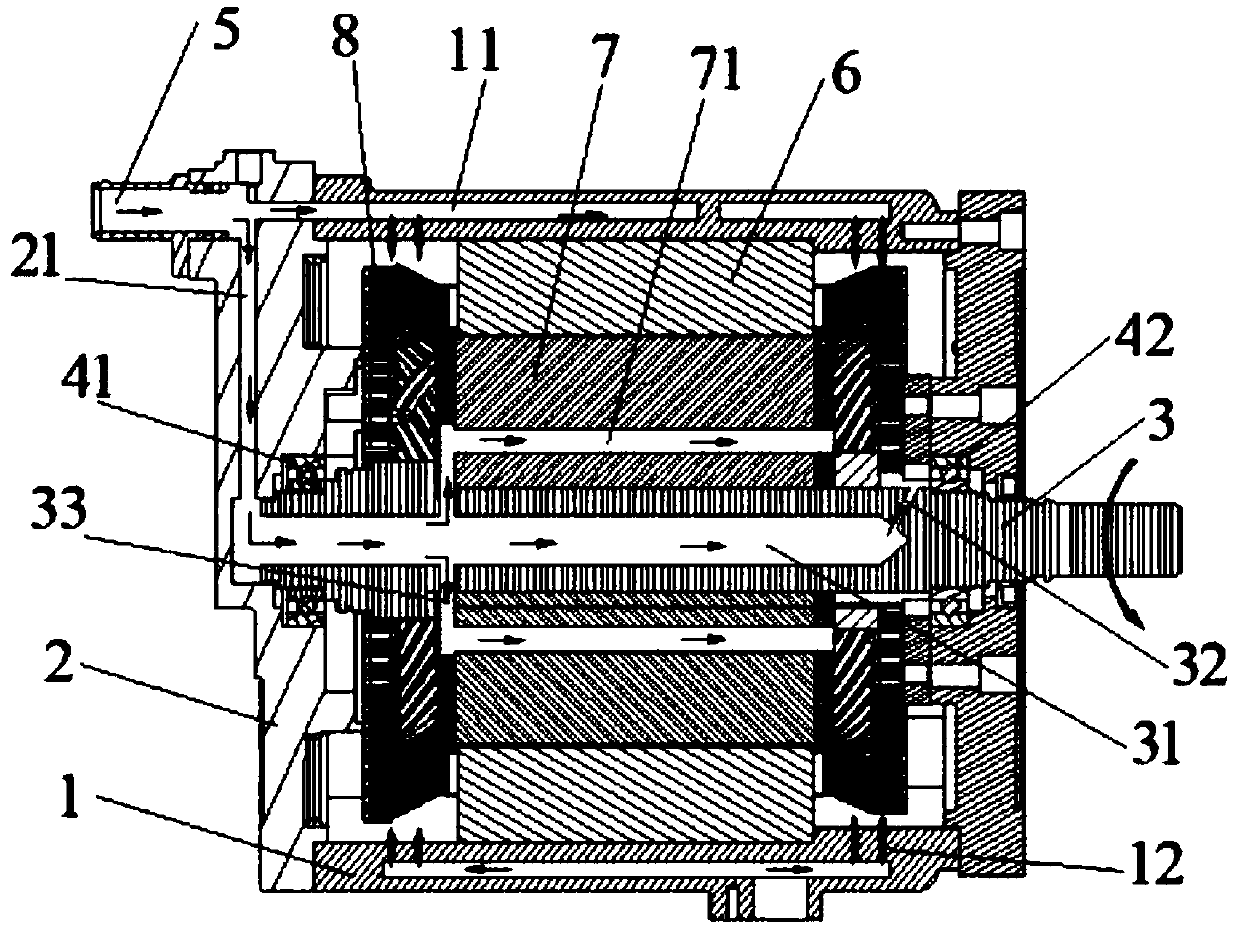

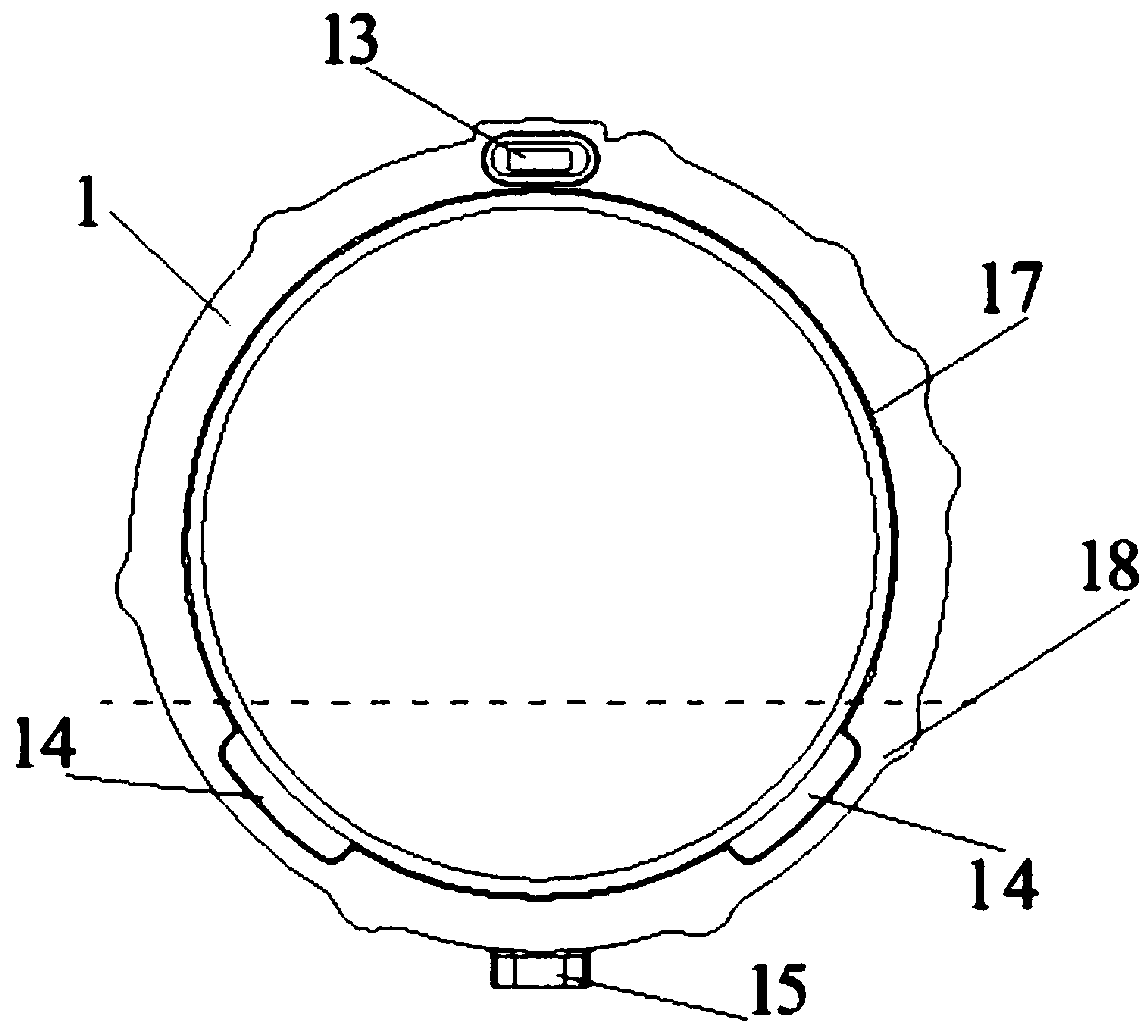

[0025] An oil-cooled structure of a permanent magnet synchronous motor, comprising a motor casing 1 , a motor end cover 2 , a rotating shaft 3 , a motor rotor 7 , and a motor stator 6 . The motor rotor 7 is set on the rotating shaft 3, and the motor winding 8 is embedded on the motor rotor. The corresponding motor stator 6 is arranged inside the motor housing 1, and the rotating shaft 3 is fitted in the motor housing 1 in a coaxial positional relationship. The two ends of the motor housing 1 are respectively sealed with motor end covers 2, and the motor shaft 3 cooperates with the shaft holes on the motor end covers 2 on both sides through the motor bearings.

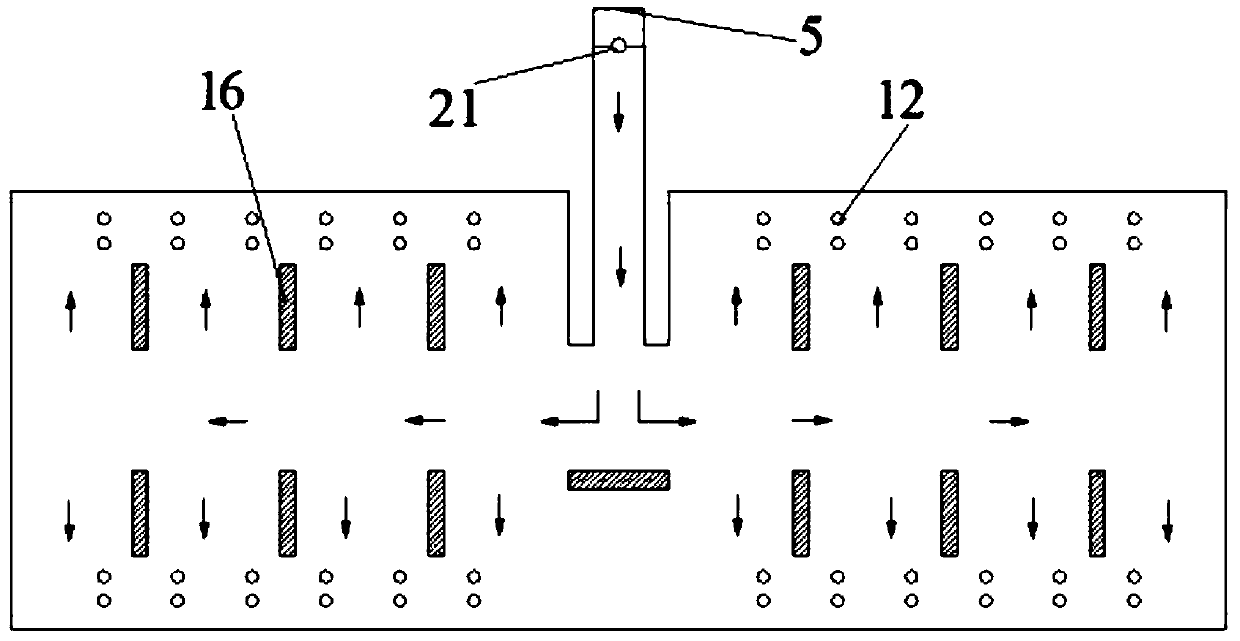

[0026] The inner wall of one of the motor end caps 2 is provided with an end cover oil passage 21, the inner wall of the motor housing 1 is provided with a housing oil passage 11, the axis of the rotating shaft 3 is provided with a rotating shaft 3 oil passages, an...

PUM

Login to View More

Login to View More Abstract

Description

Claims

Application Information

Login to View More

Login to View More - R&D

- Intellectual Property

- Life Sciences

- Materials

- Tech Scout

- Unparalleled Data Quality

- Higher Quality Content

- 60% Fewer Hallucinations

Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2025 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com