Embossing machine

A technology of embossing machine and embossing roller, which is applied in the field of embossing machines, can solve problems such as uneven embossing, affecting embossing quality, manual movement strength, and uneven precision, so as to prevent jamming or damage to equipment, embossing, etc. The quality of flower products is stable and the effect of saving manpower

- Summary

- Abstract

- Description

- Claims

- Application Information

AI Technical Summary

Problems solved by technology

Method used

Image

Examples

Embodiment Construction

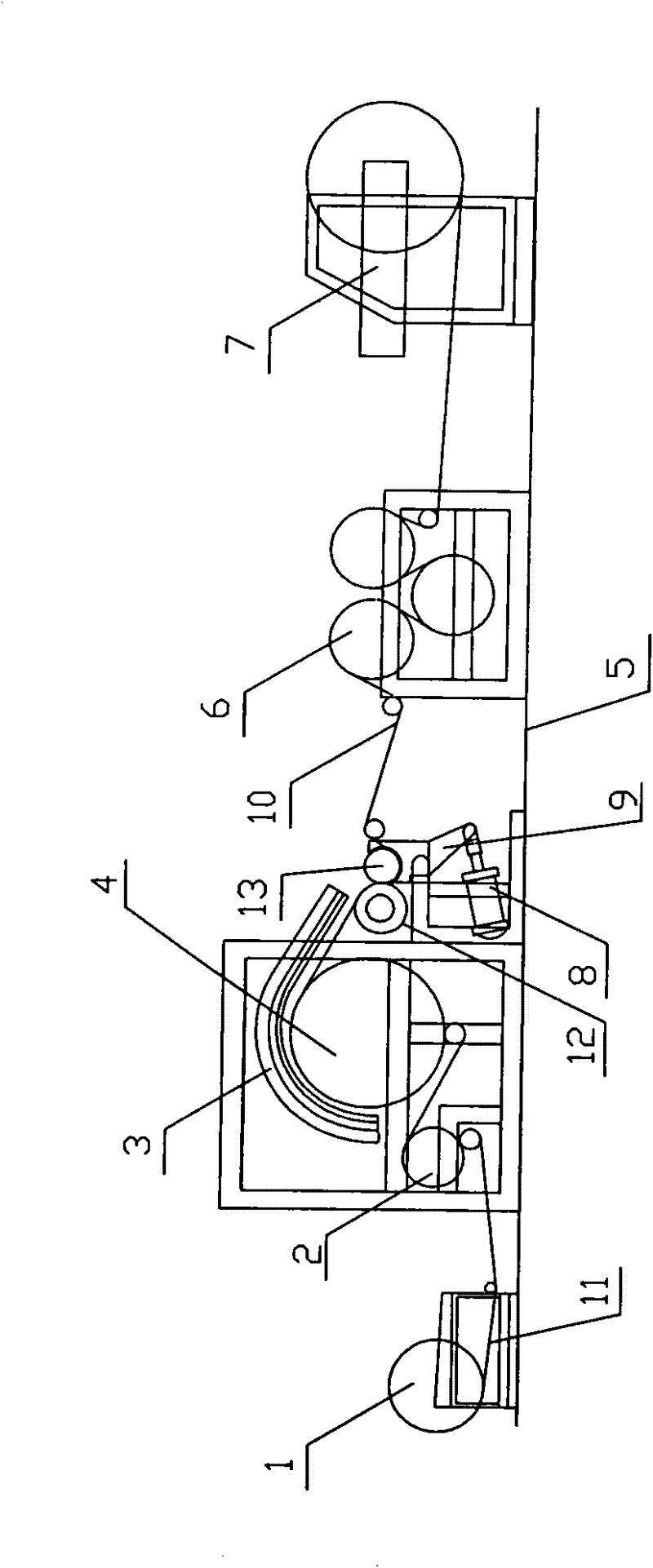

[0014] The present invention will be further described below in conjunction with the accompanying drawings and embodiments.

[0015] Such as figure 1 As shown, the press-spinning machine 5 is firstly provided with an unwinding frame 1 at the forefront, and the base blank 11 to be embossed is unfolded. After the unwinding frame 1, a preheating roller 2 is established, and the base blank 11 is preheated earlier. After the preheating roller 2, a heating roller 4 is arranged, and a heating cover 3 is arranged on the upper surface of the heating roller 4, and the preheated base blank is heated on the heating roller 4. The driving roller 12 is arranged behind the heating roller 4 to assist the embossing roller 13 . The embossing roller 13 is located on one side of the drive roller 12, and the embossing roller 13 is connected to one end of the lever transmission mechanism 9 with a supporting point. The other end of 9 is movably connected to one end of hydraulic device 8 through a ...

PUM

Login to View More

Login to View More Abstract

Description

Claims

Application Information

Login to View More

Login to View More - R&D

- Intellectual Property

- Life Sciences

- Materials

- Tech Scout

- Unparalleled Data Quality

- Higher Quality Content

- 60% Fewer Hallucinations

Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2025 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com