Bonding material and bonding method in which said bonding material is used

A technology of bonding materials and solvents, applied in the direction of welding/cutting media/materials, welding equipment, welding media, etc., can solve problems such as oxidation of joint parts, and achieve high reliability

- Summary

- Abstract

- Description

- Claims

- Application Information

AI Technical Summary

Problems solved by technology

Method used

Image

Examples

Embodiment 1

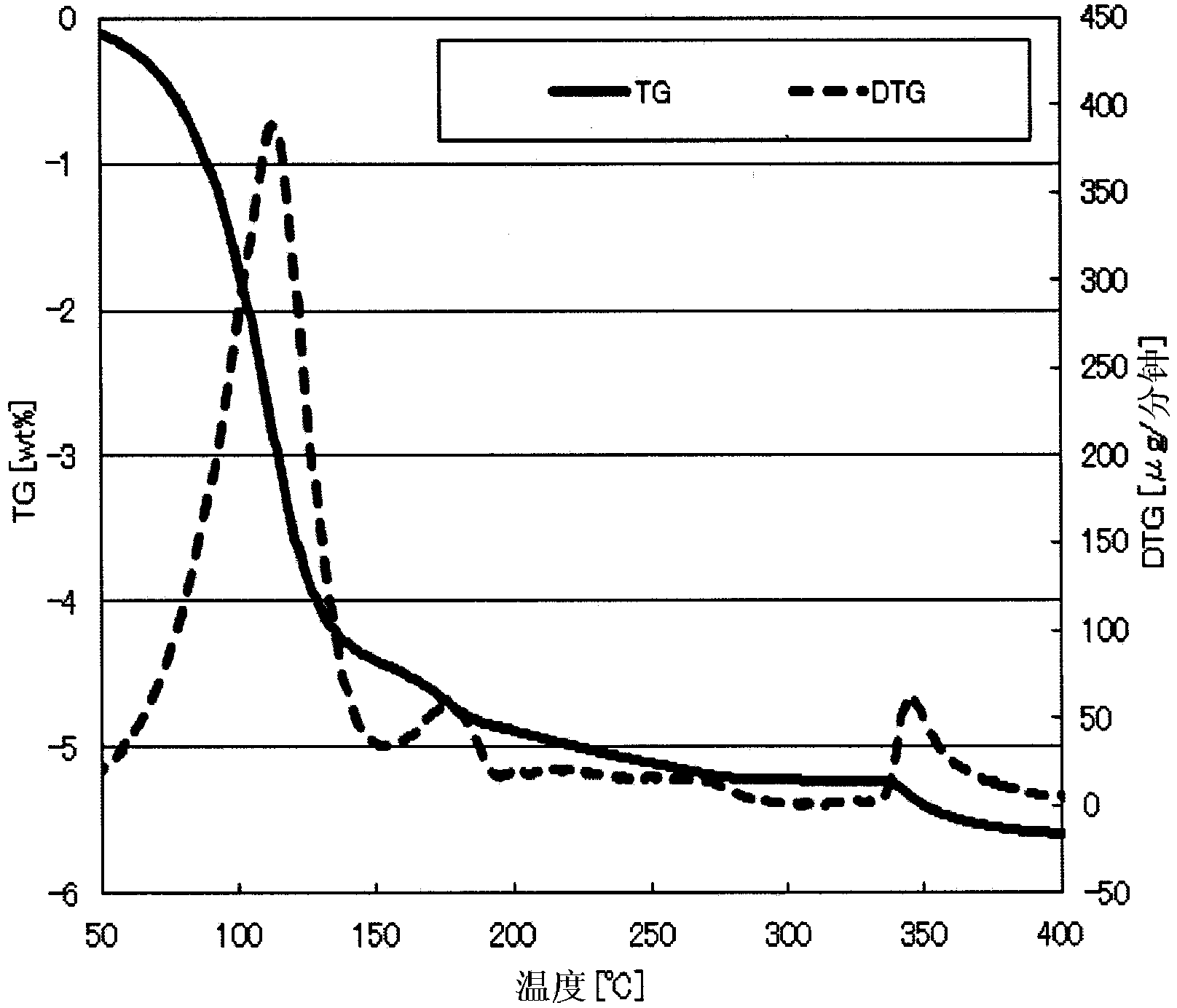

[0136] (Example 1, Comparative Example 1)

[0137] Mix the following materials to obtain a printable adhesive bonding material: as silver nanoparticles with an average primary particle size of 20nm, the caproic acid-coated silver nanoparticle powder obtained above; as a nanometer silver particle with an average primary particle size of 110nm Silver particles, the above-mentioned obtained sorbic acid-coated nano-silver particle powder; as submicron silver particles, 2-1C (manufactured by Tonghe Electronic Technology Co., Ltd.) spherical silver particle powder (average particle diameter (D 50 )800nm, wherein the particles were confirmed by SEM, and the results confirmed that the particles in the field of view were independent particles); as a low boiling point solvent, octanol with a boiling point of 194°C; as a high boiling point solvent, isobornyl ring with a boiling point of 318.3°C hexanol (MTPH); and as a dispersant, SOLPLUS D540.

[0138] In addition, as a comparative exa...

Embodiment 2

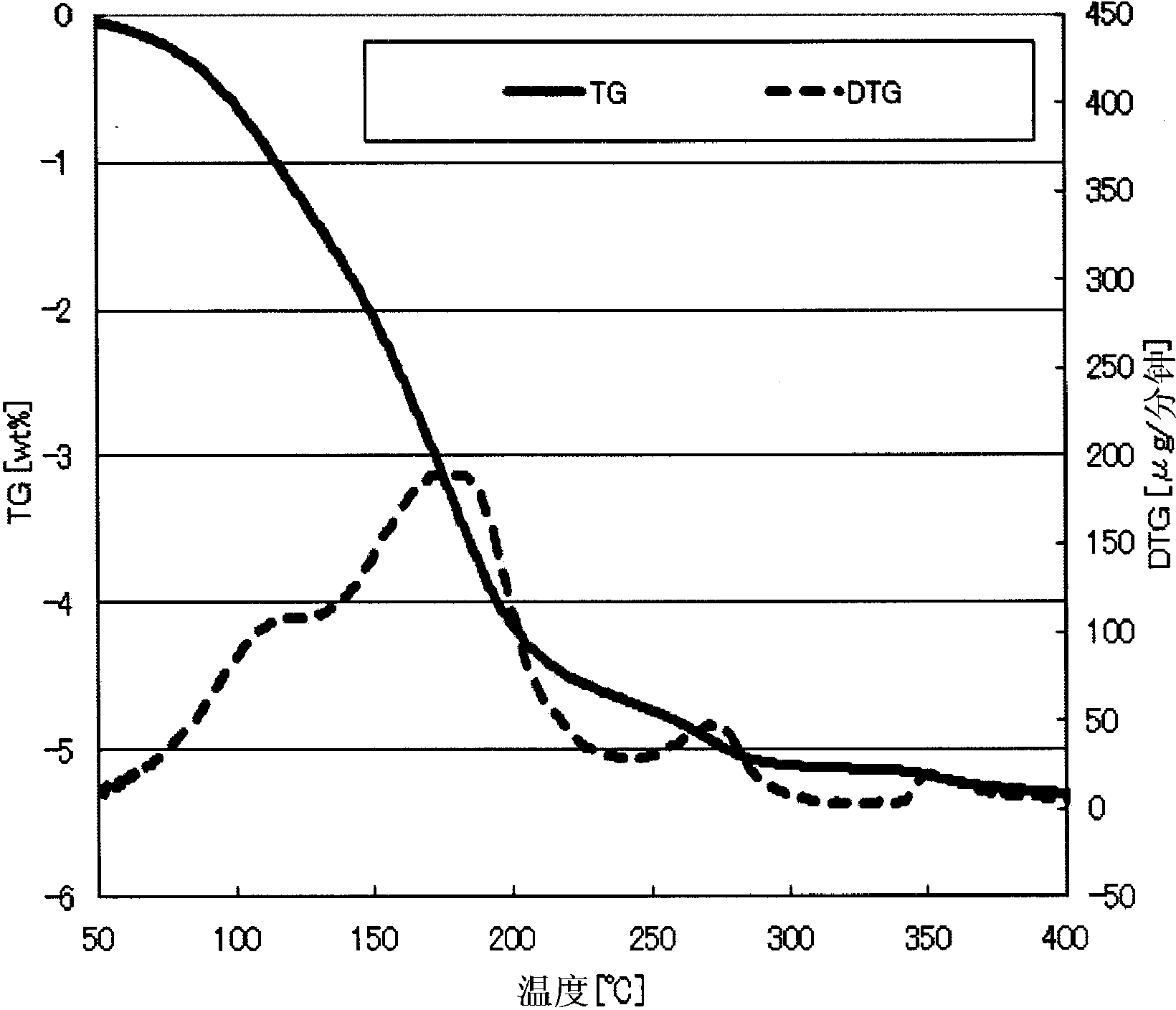

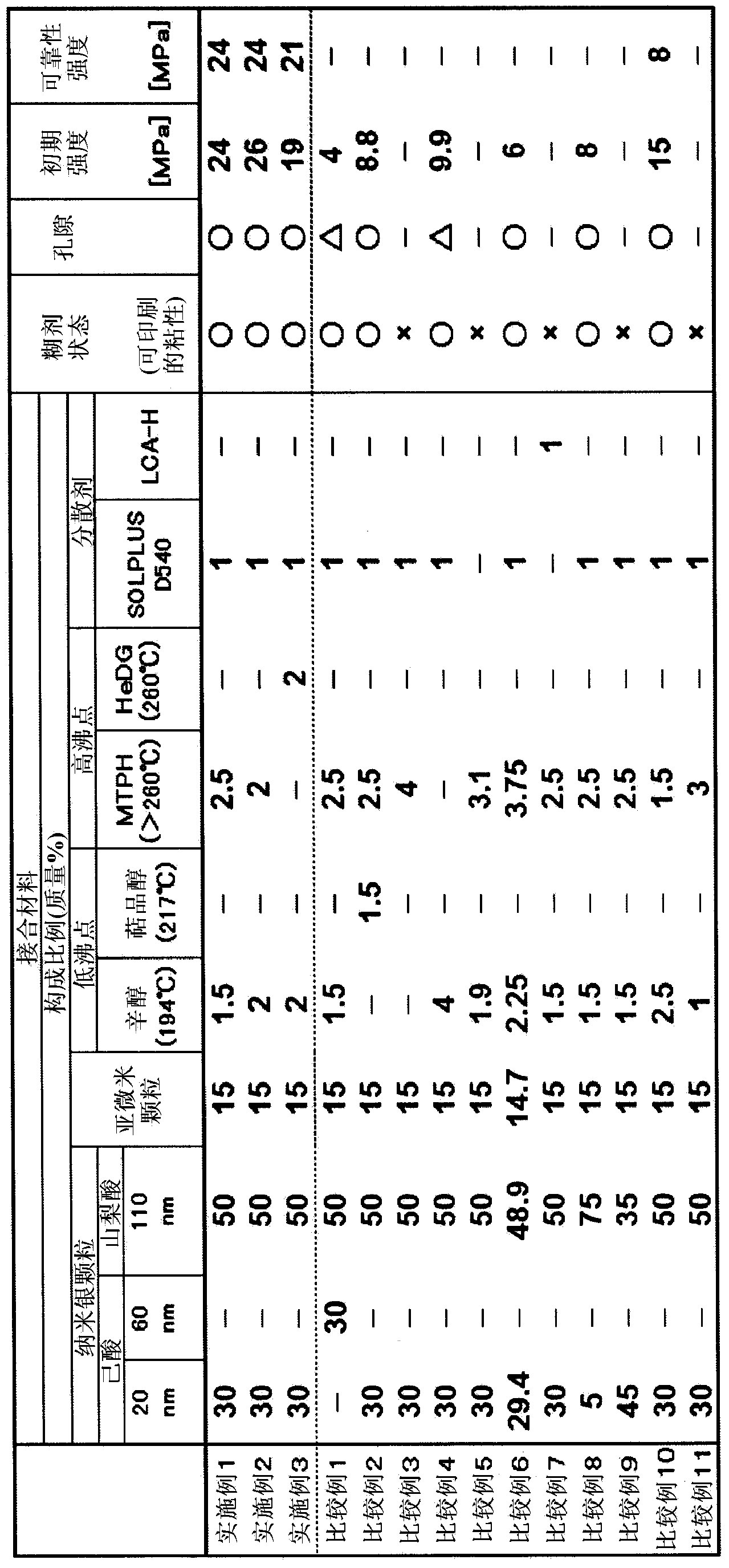

[0153] (Example 2, Comparative Examples 10, 11)

[0154] According to the ratio of the amount of low boiling point solvent to the amount of high boiling point solvent, it is low boiling point solvent: high boiling point solvent = 1:1 coordination embodiment 2, according to low boiling point solvent: high boiling point solvent = 5:3 coordination of comparative example 10, and according to Low boiling point solvent: high boiling point solvent = 1:3 The bonding material of Comparative Example 11 was prepared under the conditions shown in Table 1, and was produced in the same manner as in Example 1. The obtained results are shown in Table 1 together.

[0155] In addition, the ratio of the amount of low-boiling-point solvent to the amount of high-boiling-point solvent in Example 1 is low-boiling-point solvent:high-boiling-point solvent=3:5. In Comparative Example 10 in which the amount of the low-boiling-point solvent was more than half, the paste state was good and voids were not...

Embodiment 3

[0157] A bonding material was produced in the same manner as in Example 1 except that diethylene glycol hexyl ether (HeDG) having a boiling point of 260° C. was used as a usage example in which a high boiling point solvent was different. The obtained results are shown in Table 1 together. The state of the paste, the generation of voids, the initial bonding strength, and the reliability strength were all good results as in Example 1.

[0158] [Table 1]

[0159]

PUM

| Property | Measurement | Unit |

|---|---|---|

| particle diameter | aaaaa | aaaaa |

| particle diameter | aaaaa | aaaaa |

| particle diameter | aaaaa | aaaaa |

Abstract

Description

Claims

Application Information

Login to View More

Login to View More - R&D

- Intellectual Property

- Life Sciences

- Materials

- Tech Scout

- Unparalleled Data Quality

- Higher Quality Content

- 60% Fewer Hallucinations

Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2025 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com