Reciprocating straight-line and rotating motion grinding polishing device

A rotary motion, reciprocating straight line technology, used in grinding/polishing equipment, surface-polished machine tools, metal processing equipment, etc. The effect of flatness and finish as well as parallelism, uniform distribution of abrasive particles

- Summary

- Abstract

- Description

- Claims

- Application Information

AI Technical Summary

Problems solved by technology

Method used

Image

Examples

Embodiment Construction

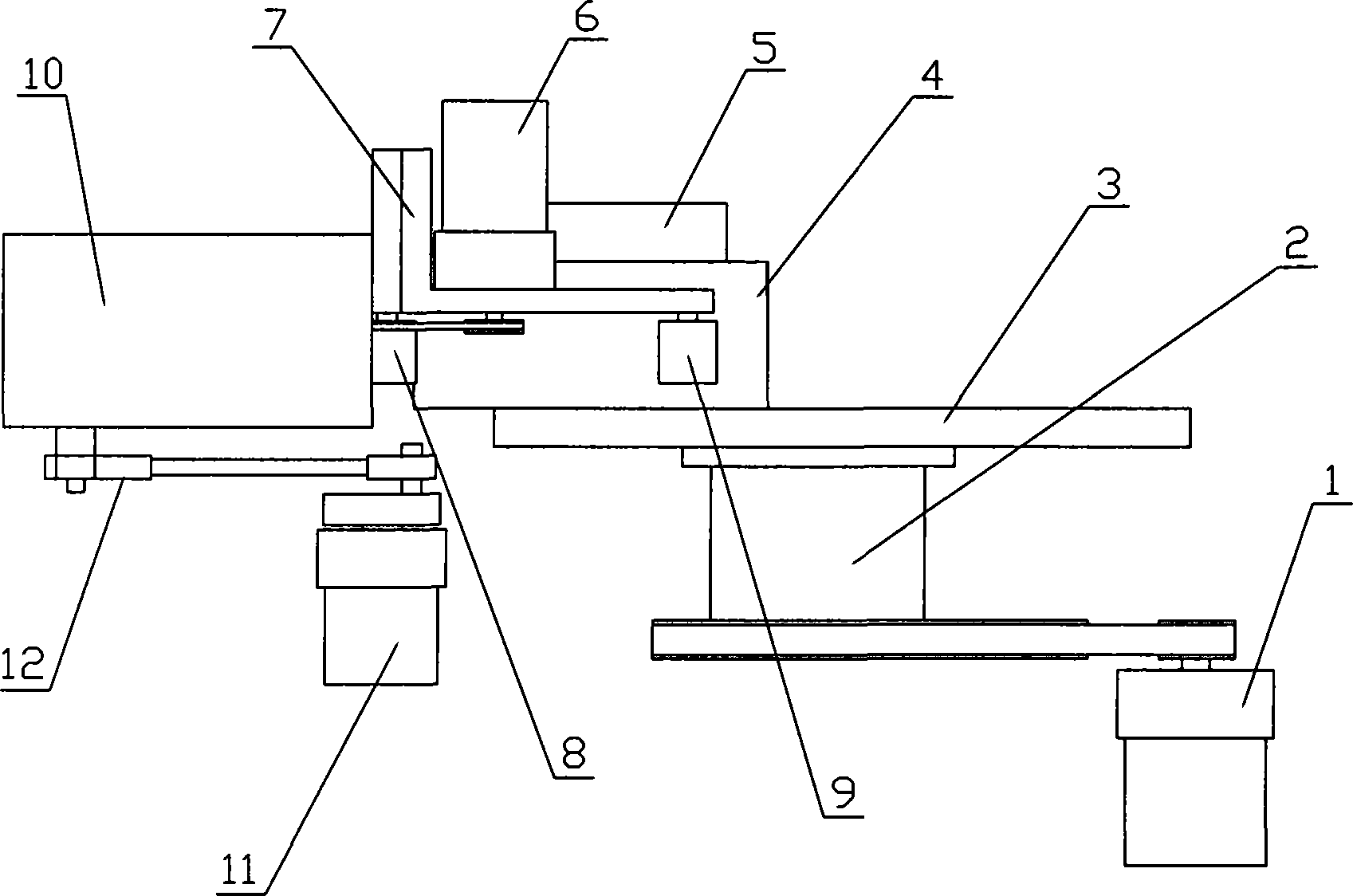

[0019] The present invention will be described in detail below with reference to the accompanying drawings.

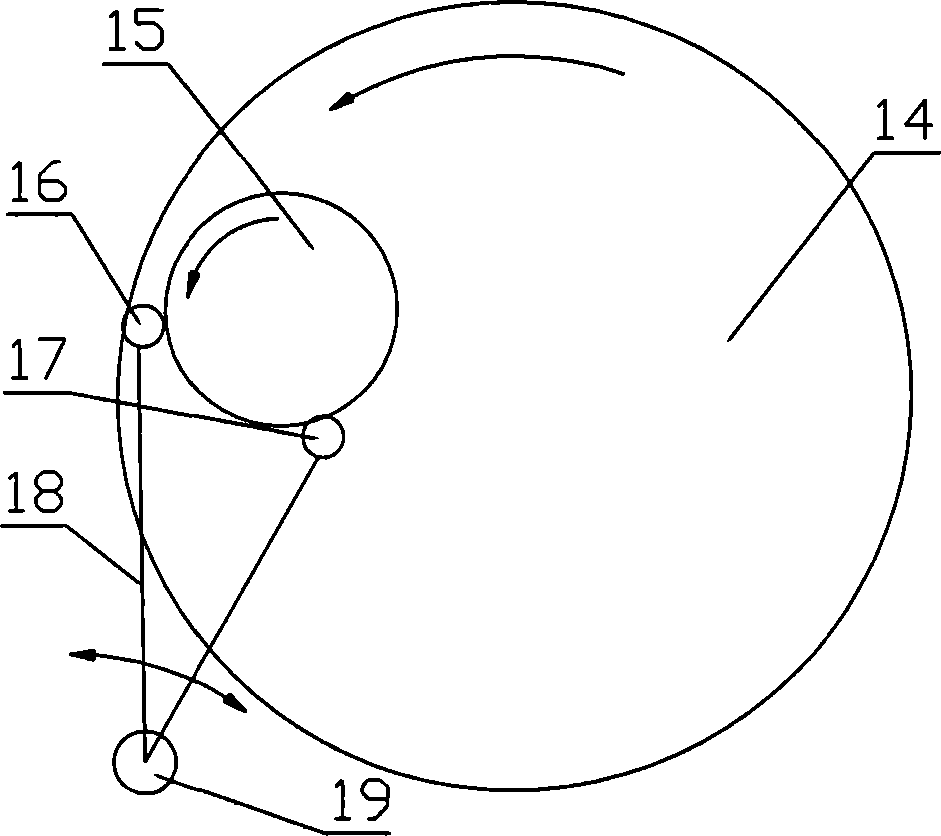

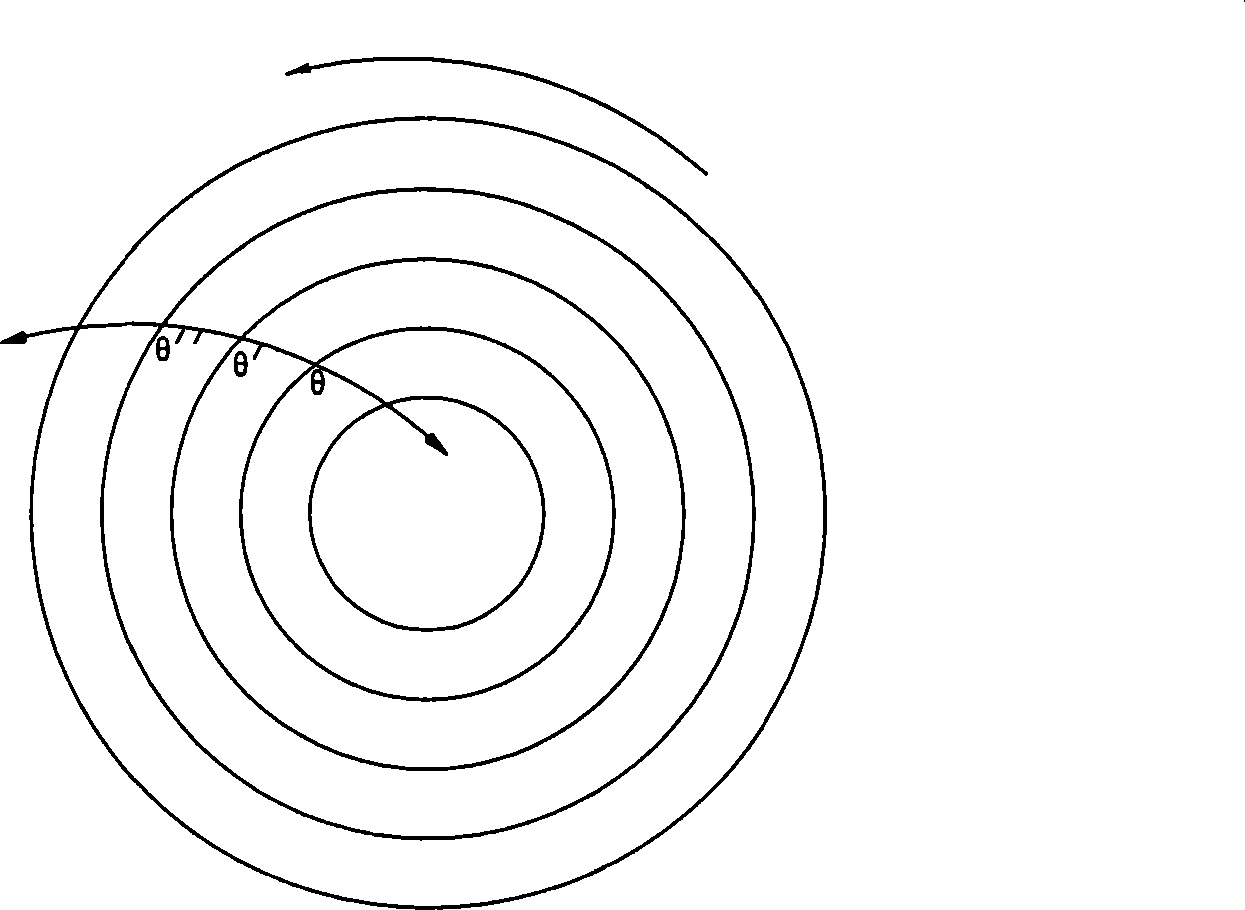

[0020] Such as image 3 , 4 As shown, the grinding and polishing device includes a grinding and polishing disc 3, a rotating body 2, a grinding and polishing disc driving motor 1, a loading tray 5, a loading tray bracket 7, an active bracket guide wheel 8, a passive bracket guide wheel 9, and a guide wheel drive Motor 6, linear guide rail seat 10, guide rail driving motor 11, eccentric driving lever 12 and trimming ring 4. Wherein, the surface of the loading disc 5 is glued with the material to be ground and polished, and it faces to be placed on the disc surface of the grinding and polishing disc 3; . The trimming ring 4 is placed among the active support guide wheel 8 and the passive support guide wheel 9, and the active support guide wheel 8 is driven by the motor on the loading tray support 7, and the passive support guide wheel 9 is a passive wheel, which can m...

PUM

Login to View More

Login to View More Abstract

Description

Claims

Application Information

Login to View More

Login to View More - R&D

- Intellectual Property

- Life Sciences

- Materials

- Tech Scout

- Unparalleled Data Quality

- Higher Quality Content

- 60% Fewer Hallucinations

Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2025 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com