Fully automatic floor tile laying machine

A fully automatic, laying machine technology, applied in the direction of construction, building construction, etc., can solve problems such as poor laying effect, achieve the effect of improving laying effect, improving utilization rate, and improving compaction effect

- Summary

- Abstract

- Description

- Claims

- Application Information

AI Technical Summary

Problems solved by technology

Method used

Image

Examples

Embodiment Construction

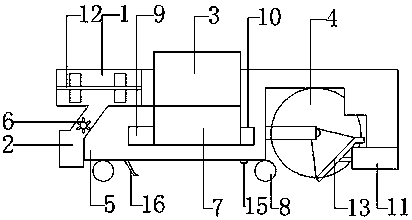

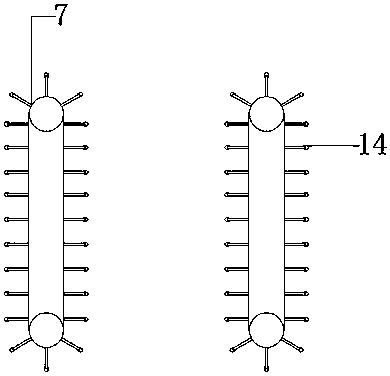

[0021] A fully automatic floor tile laying machine, mainly comprising: cement storage box 1, cement discharge device 2, floor tile storage box 3, compacting device 4 and base 5, characterized in that: cement discharge device 2 contains impeller 6, floor tile The storage box 3 contains a floor tile laying device 7; the front end of the device is a cement discharge device 2, the upper end of the cement discharge device 2 is connected to a cement storage box 1, the lower end of the cement discharge device 2 is connected to a plastering device 16, and the cement discharge device 2 No. 1 motor 9, No. 1 motor 9 has floor tile holding box 3 behind it, and floor tile holding box 3 lower end has floor tile laying device 7, and floor tile holding box 3 is connected with No. 2 motor 10, and No. 2 motor 10 is connected with pressure The compacting device 4 has a cement recovery box 11 behind the compacting device 4. The whole device is placed on the base 5, and the lower end of the base 5 ...

PUM

Login to View More

Login to View More Abstract

Description

Claims

Application Information

Login to View More

Login to View More - R&D

- Intellectual Property

- Life Sciences

- Materials

- Tech Scout

- Unparalleled Data Quality

- Higher Quality Content

- 60% Fewer Hallucinations

Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2025 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com