Bottom sealing twin arc welding method of large-caliber industrial pure titanium pipelines

A technology of industrial pure titanium and welding methods, applied in welding equipment, arc welding equipment, manufacturing tools, etc., can solve the problems of high welder operation skills, large consumption of argon gas, slow welding speed, etc., and achieve easy control of weld formation The effect of high quality, saving argon filling cost, and fast welding speed

- Summary

- Abstract

- Description

- Claims

- Application Information

AI Technical Summary

Problems solved by technology

Method used

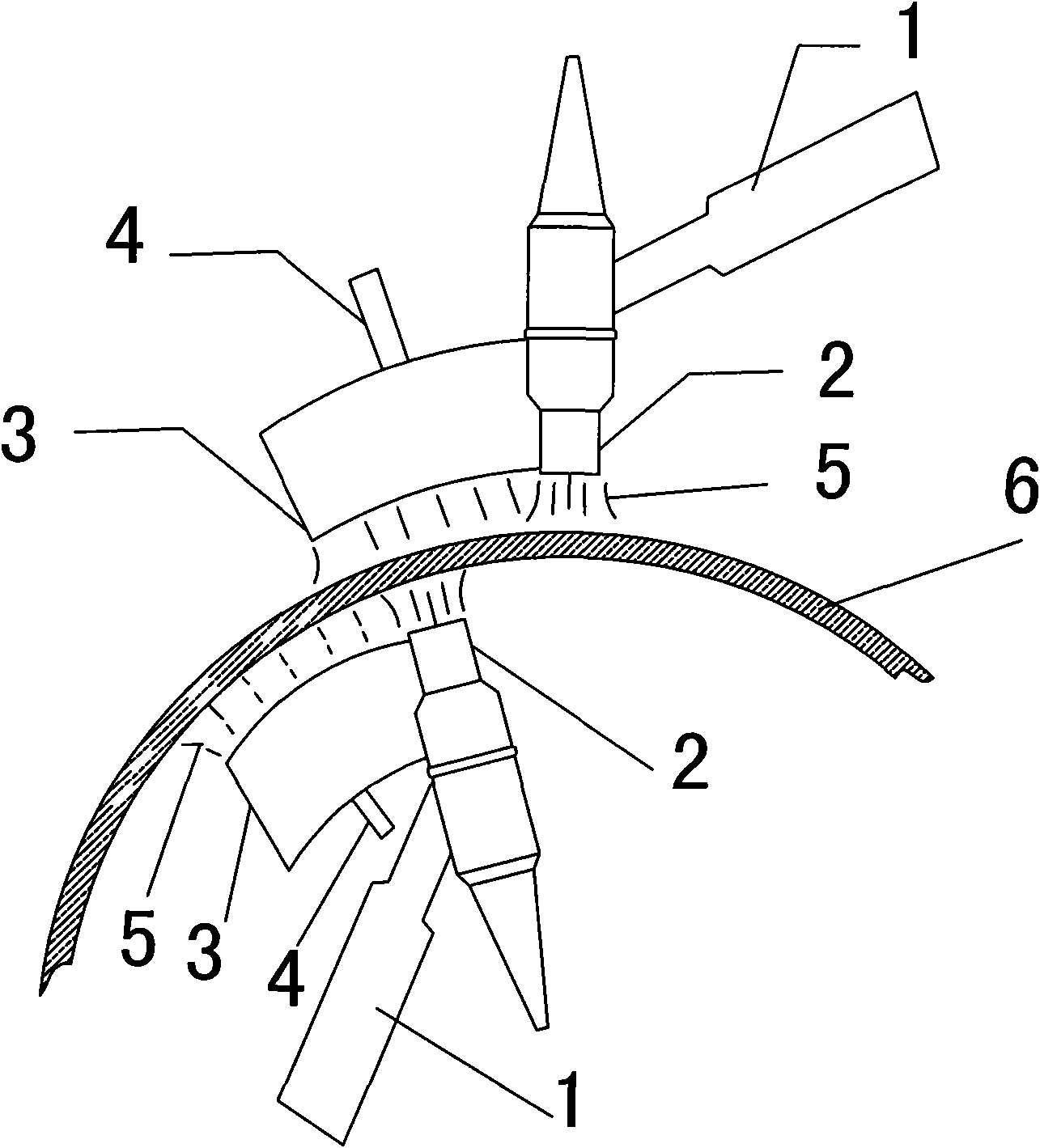

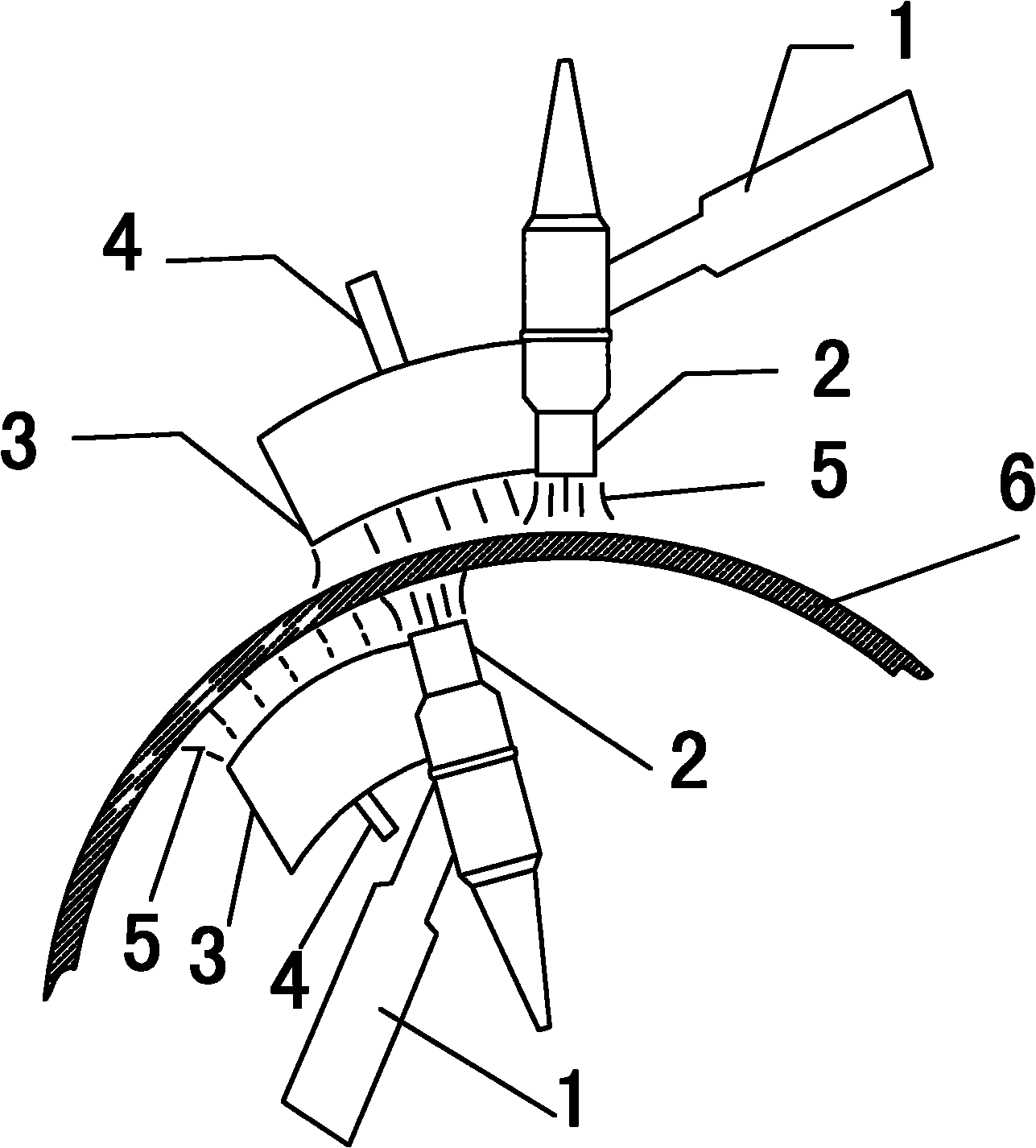

Image

Examples

Embodiment 1

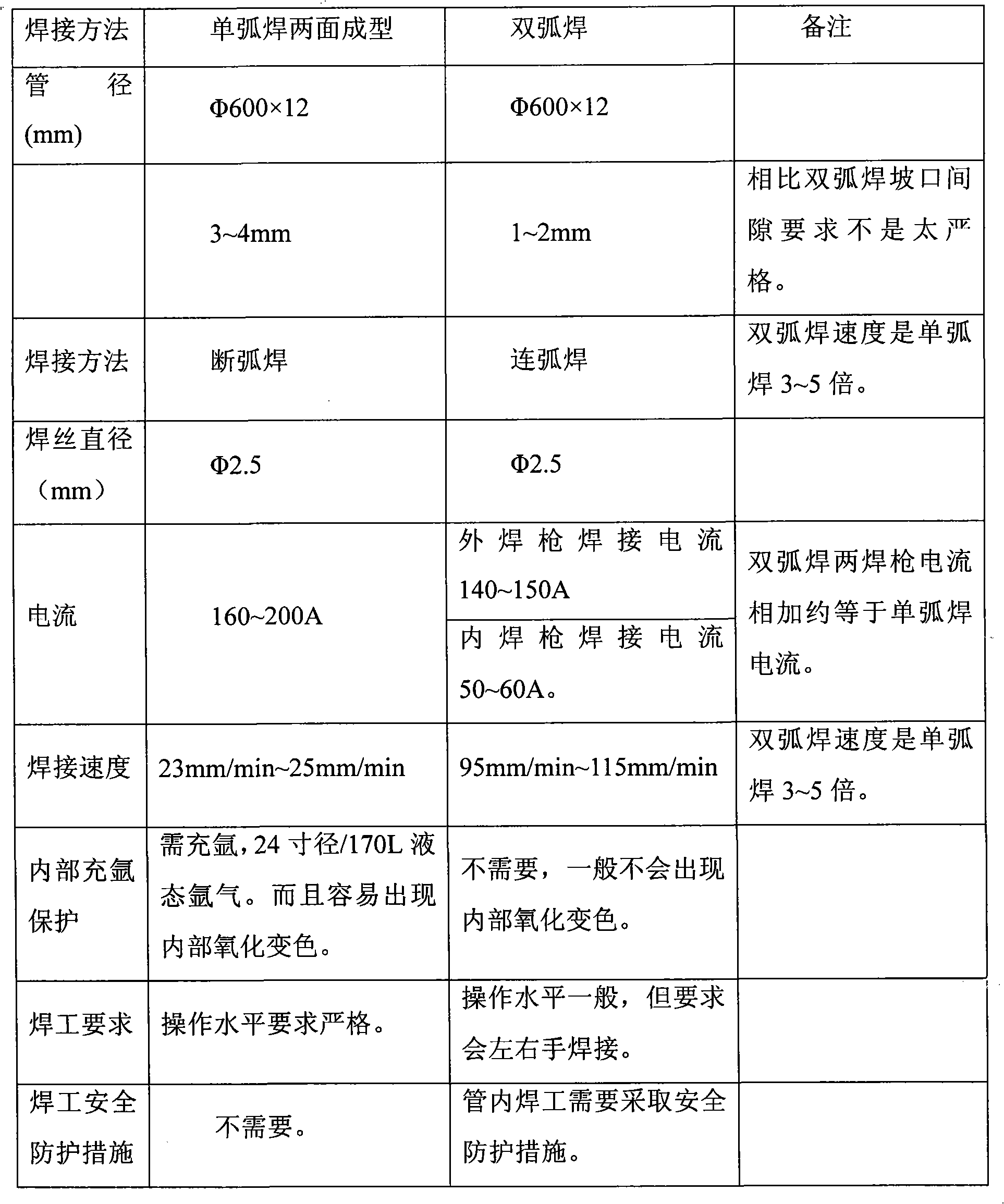

[0034] Titanium pipe Φ600×12mm pipe process parameters

[0035] 1. Clean up the oil and oxide on the surface of welding wire and weldment;

[0036] 2. V-shaped bevel processing on the nozzle;

[0037] 3. Carry out pipe assembly, the groove gap is 1mm;

[0038] 4. Two welding torches inside and outside the titanium pipeline work together to weld the titanium pipeline. A tungsten argon arc welding torch with a protective tow cover is used. When welding, the welding direction is followed. 25L / min, inner torch nozzle argon flow 15L / min, outer torch drag hood argon flow 25L / min, inner torch drag hood argon flow 25L / min, outer torch current 140A, inner torch current 50A, outer torch voltage 14V , the voltage of the inner welding torch is 13V, the welding speed of the outer welding torch is 95mm / min, the welding speed of the inner welding torch is 95mm / min, and the distance between the front and rear arcs of the inner and outer welding torches is 4mm.

[0039] 5. The arc of the ex...

Embodiment 2

[0045] Titanium pipe Φ800×12mm pipe process parameters

[0046] 1. Clean up the oil and oxide on the surface of welding wire and weldment;

[0047] 2. V-shaped bevel processing on the nozzle;

[0048] 3. Carry out pipe assembly, the groove gap is 1.5mm;

[0049] 4. Two welding torches inside and outside the titanium pipeline work together to weld the titanium pipeline. A tungsten argon arc welding torch with a protective drag cover is used. When welding, the welding torch nozzle is in front of the protective drag cover and the argon flow rate of the outer welding torch nozzle is adjusted according to the welding direction. 30L / min, inner torch nozzle argon flow 20L / min, outer torch drag hood argon flow 30L / min, inner torch drag hood argon flow 30L / min, outer torch current 145A, inner torch current 50A, outer torch voltage 15V , the voltage of the inner welding torch is 14V, the welding speed of the outer welding torch is 100mm / min, the welding speed of the inner welding torc...

Embodiment 3

[0056] Titanium pipe Φ1500×12mm pipe welding

[0057] 1. Clean up the oil and oxide on the surface of welding wire and weldment;

[0058] 2. V-shaped bevel processing on the nozzle;

[0059] 3. Carry out pipe assembly, the groove gap is 2mm;

[0060] 4. Two welding torches inside and outside the titanium pipeline work together to weld the titanium pipeline. A tungsten argon arc welding torch with a protective drag cover is used. When welding, the welding torch nozzle is in front of the protective drag cover and the argon flow rate of the outer welding torch nozzle is adjusted according to the welding direction. 30L / min, inner torch nozzle argon flow 20L / min, outer torch drag hood argon flow 35L / min, inner torch drag hood argon flow 30L / min, outer torch current 150A, inner torch current 60A, outer torch voltage 15V , the voltage of the inner welding torch is 15V, the welding speed of the outer welding torch is 115mm / min, the welding speed of the inner welding torch is 115mm / m...

PUM

| Property | Measurement | Unit |

|---|---|---|

| diameter | aaaaa | aaaaa |

Abstract

Description

Claims

Application Information

Login to View More

Login to View More - R&D

- Intellectual Property

- Life Sciences

- Materials

- Tech Scout

- Unparalleled Data Quality

- Higher Quality Content

- 60% Fewer Hallucinations

Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2025 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com