Preparation method for CdS flower-shaped self-assembly structure and obtained product

A self-assembly and sheet-like structure technology, applied in the direction of cadmium sulfide, can solve the problems of unfavorable product precise control and large-scale production, poor controllability of microscopic morphology, complex synthesis process, etc., and achieve high physical and chemical stability and photoelectricity Effects of response properties, narrow size distribution range, and low raw material cost

- Summary

- Abstract

- Description

- Claims

- Application Information

AI Technical Summary

Problems solved by technology

Method used

Image

Examples

Embodiment 1

[0030] 1.1 Add 0.143g of cadmium chloride (CdCl 2 2.5H 2 O), 2.000g of PVP, 20.0mL of ethylene glycol, 30.0mL of ethylenediamine and 0.230g of thiourea were added to 10.0mL of water, and stirred to obtain a transparent solution;

[0031] 1.2 Transfer the above solution to the reactor and react at 160°C for 24 hours;

[0032] 1.3 After the reaction is over, the product is obtained after centrifugation and washing.

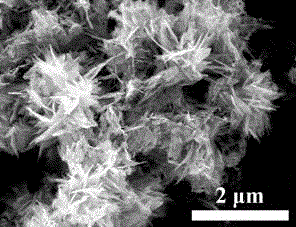

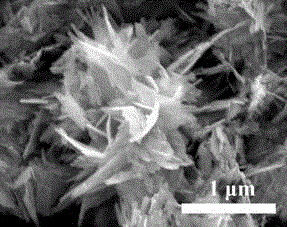

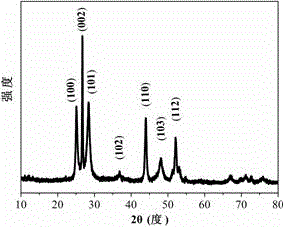

[0033] SEM of the product as figure 1 and 2 As shown, it can be seen from the figure that the obtained product is flower-shaped, with an average diameter of 1.6 μm. The flower-like structure is self-assembled by the CdS sheet-like structure, and the average thickness of the CdS sheet-like structure is 20nm; XRD results such as image 3 As shown, the XRD results are consistent with the standard XRD card (41-1049), which proves that the crystal phase of the obtained product is the wurtzite structure α-CdS phase; the change curve of the photocurrent intensity of t...

Embodiment 2

[0035] 2.1 Add 0.100g of CdCl 2 2.5H 2 O. The PVP of 0.374g, the ethylene glycol of 14.4mL, the ethylenediamine of 24.3mL and the thiourea of 0.103g join in 10.0mL water, stir to obtain transparent solution;

[0036] 2.2 Transfer the above solution to the reactor and react at 150°C for 2 hours;

[0037] 2.3 After the reaction, the flower-like self-assembled structure was obtained after centrifugation and washing. The average diameter of the CdS flower-like self-assembled structure is 0.18 μm, and the average thickness of the basic structural unit CdS sheet structure is 7 nm. The XRD pattern of the product and image 3 similar.

Embodiment 3

[0039] 3.1 Add 0.222g of CdCl 2 2.5H 2 O. The PVP of 3.81g, the ethylene glycol of 34.4mL, the ethylenediamine of 25.6mL and the thiourea of 0.350g join in 8.0mL water, stir to obtain transparent solution;

[0040] 3.2 Transfer the above solution to the reactor and react at 150°C for 28 hours;

[0041] 3.3 After the reaction, the flower-like self-assembled structure was obtained after centrifugation and washing. The average diameter of the CdS flower-like self-assembled structure is 1.4 μm, and the average thickness of the basic structural unit CdS sheet structure is 16 nm. The XRD pattern of the product and image 3 similar.

PUM

| Property | Measurement | Unit |

|---|---|---|

| size | aaaaa | aaaaa |

| thickness | aaaaa | aaaaa |

| diameter | aaaaa | aaaaa |

Abstract

Description

Claims

Application Information

Login to View More

Login to View More - R&D

- Intellectual Property

- Life Sciences

- Materials

- Tech Scout

- Unparalleled Data Quality

- Higher Quality Content

- 60% Fewer Hallucinations

Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2025 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com