Model predictive control performance evaluation and diagnosis method

A technology of model predictive control and diagnostic methods, applied in testing/monitoring control systems, general control systems, electrical testing/monitoring, etc., can solve problems affecting product quality, poor performance, slow progress, etc.

- Summary

- Abstract

- Description

- Claims

- Application Information

AI Technical Summary

Problems solved by technology

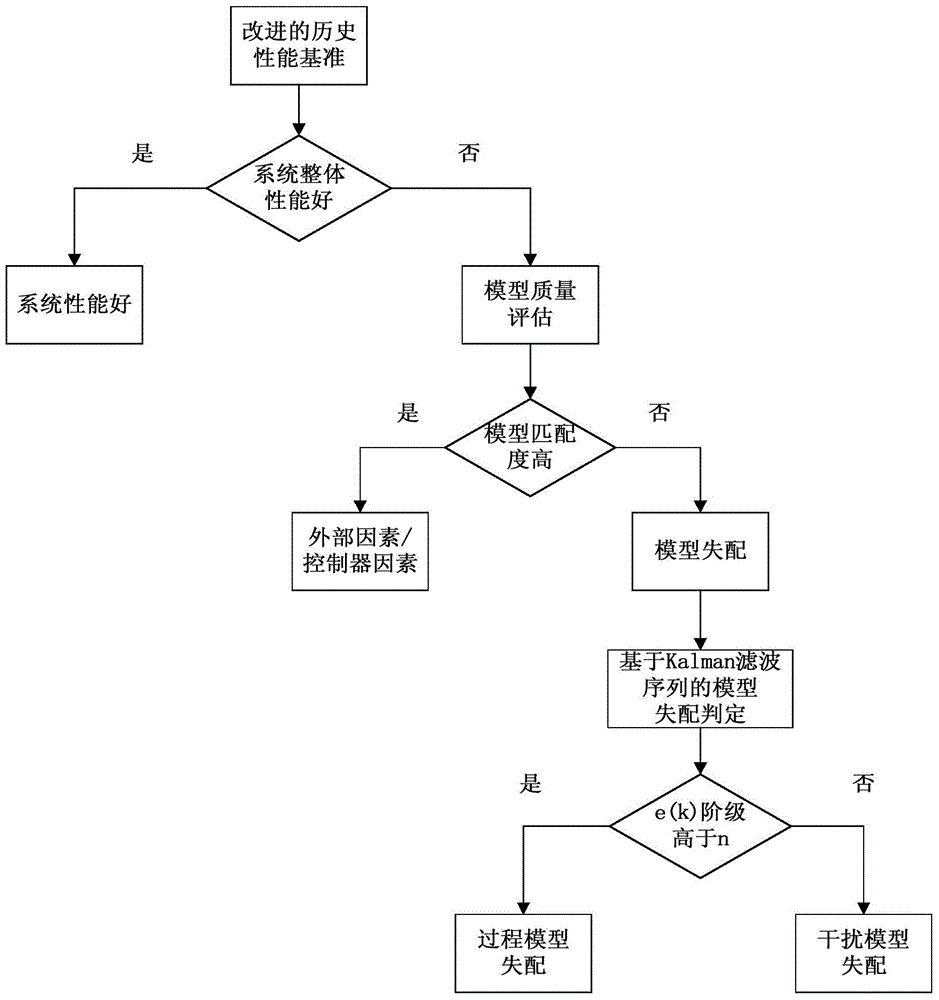

Method used

Image

Examples

Embodiment Construction

[0099] In order to make the technical means, creative features, goals and effects achieved by the present invention easy to understand, the present invention will be further described below in conjunction with specific embodiments.

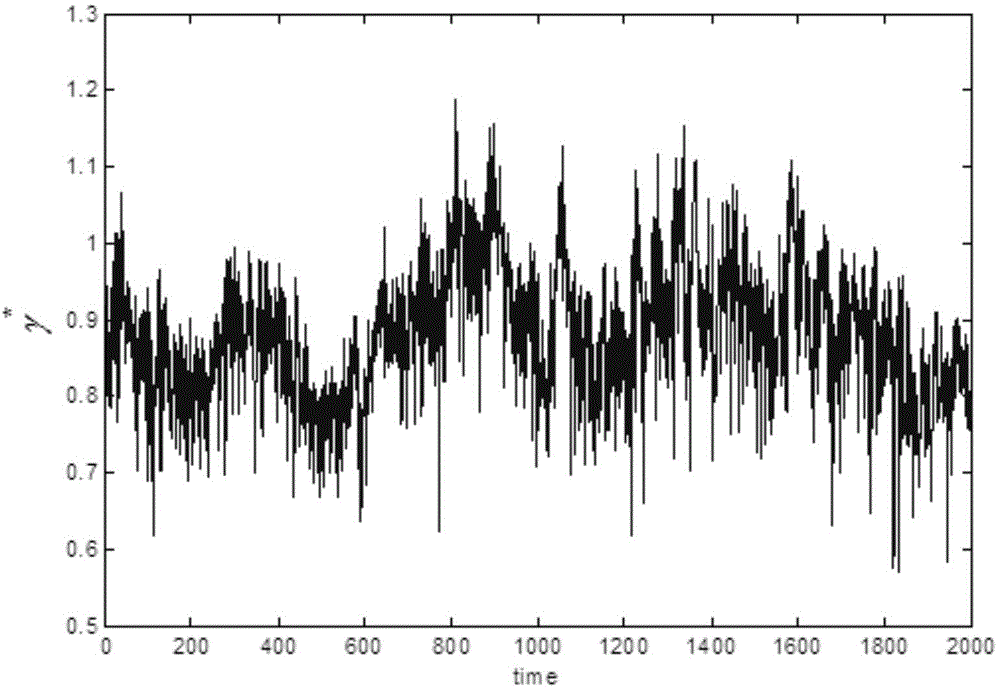

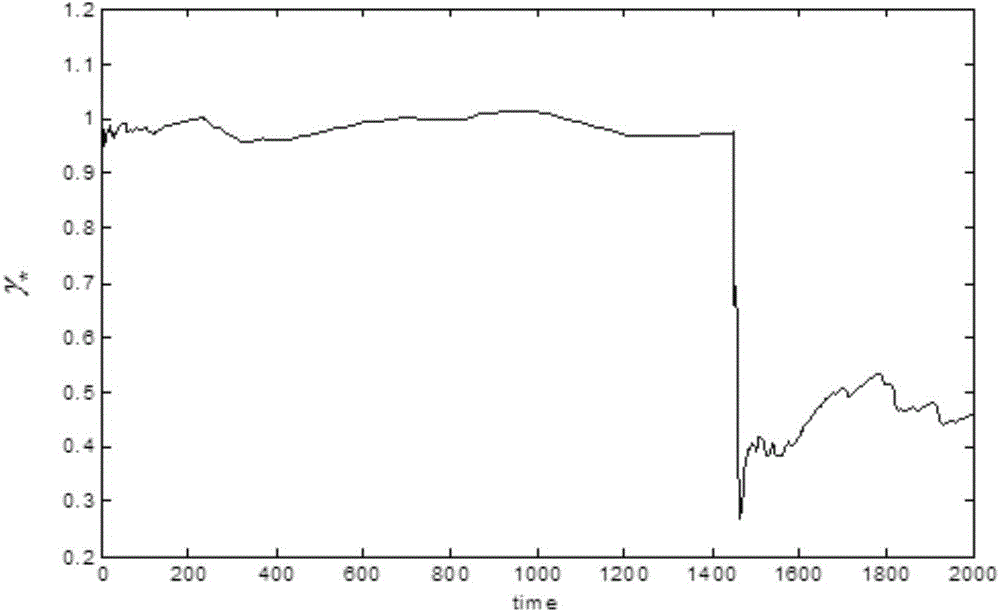

[0100] The present invention first aims at the limitation that model predictive controllers generally cannot achieve the minimum variance benchmark and the complexity of the calculation of the correlation matrix. The method obtains the system performance through the ratio of the system benchmark performance to the real-time performance, and only needs conventional closed-loop input and output data to solve the problem. In order to eliminate the drawbacks of previous historical performance benchmarks that required prior knowledge to obtain a period of well-running data, the specific system performance indicators are as follows:

[0101] γ * ( k ) = ...

PUM

Login to View More

Login to View More Abstract

Description

Claims

Application Information

Login to View More

Login to View More - R&D

- Intellectual Property

- Life Sciences

- Materials

- Tech Scout

- Unparalleled Data Quality

- Higher Quality Content

- 60% Fewer Hallucinations

Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2025 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com