Model mismatching diagnosis method of data driven multivariable control system

A multi-variable control and data-driven technology, applied in general control systems, control/adjustment systems, test/monitoring control systems, etc., can solve problems such as model mismatch, high system maintenance costs, and low system security, and achieve savings Production costs, avoiding economic losses, and reducing system maintenance costs

- Summary

- Abstract

- Description

- Claims

- Application Information

AI Technical Summary

Problems solved by technology

Method used

Image

Examples

Embodiment 1

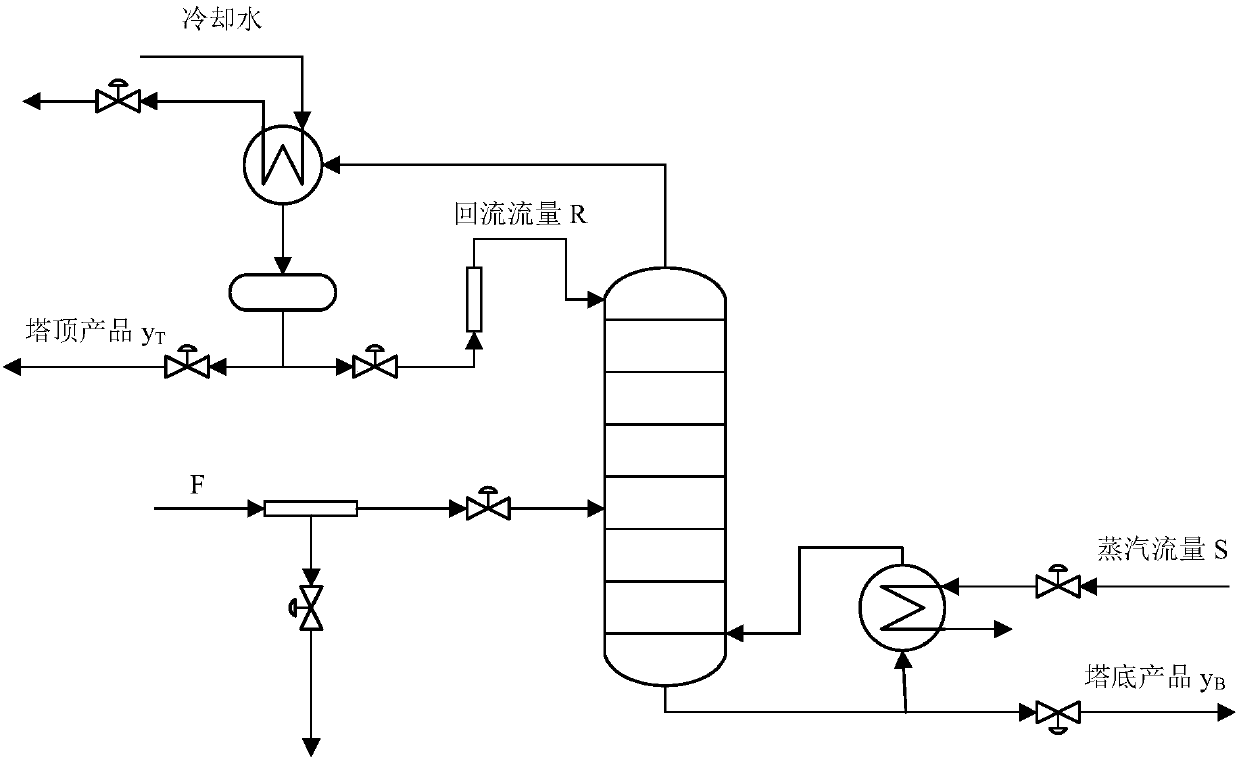

[0135] Wood-Berry distillation column process such as image 3 As shown, it is a simulation process of methanol-water mixing. It is a chemical process model proposed by Wood and Berry to study and evaluate process control technology and performance monitoring. The details of the rectification process of the Wood-Berry rectification tower are as follows: (1) raw material D enters from the feed plate, and the feed plate divides the whole rectification tower into a rectification section and a stripping section; (2) the solution enters the rectification section. After the distillation tower, because methanol and water have different boiling points, the low-boiling point components are easily vaporized and rise upwards, while the high-boiling point components mostly flow down with the liquid and combine with the rising steam in the distillation tower. Full contact is carried out on the trays of each layer to carry out the heat transfer and mass transfer process; (3) After the liqui...

PUM

Login to View More

Login to View More Abstract

Description

Claims

Application Information

Login to View More

Login to View More - R&D

- Intellectual Property

- Life Sciences

- Materials

- Tech Scout

- Unparalleled Data Quality

- Higher Quality Content

- 60% Fewer Hallucinations

Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2025 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com