Self-adaptive scanning speed method for improving molding quality of hanging body model

A technology of scanning speed and molding quality, applied in the field of adaptive scanning speed to improve the molding quality of the pendant model, can solve the problems of increasing material consumption and cost, prolonging the molding time of the model, etc., to save consumption and improve the effect.

- Summary

- Abstract

- Description

- Claims

- Application Information

AI Technical Summary

Problems solved by technology

Method used

Image

Examples

Embodiment Construction

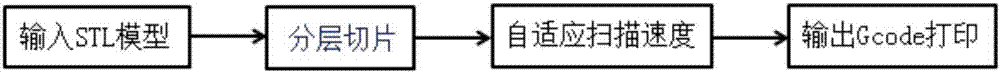

[0032] The present invention will be further explained below in conjunction with the drawings. The algorithm flow is as follows Figure 5 Shown.

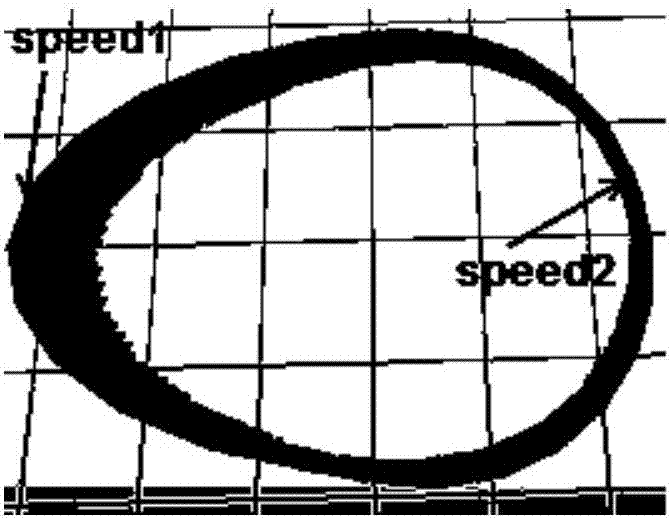

[0033] An adaptive scanning speed method to improve the quality of the suspension model, such as Figure 1 to Figure 5 As shown, including the following steps:

[0034] Step A1: Establish the topological structure of the triangular facets in the STL model based on their vertices and normal vector information; the data structure describing the topological information is:

[0035]

[0036]

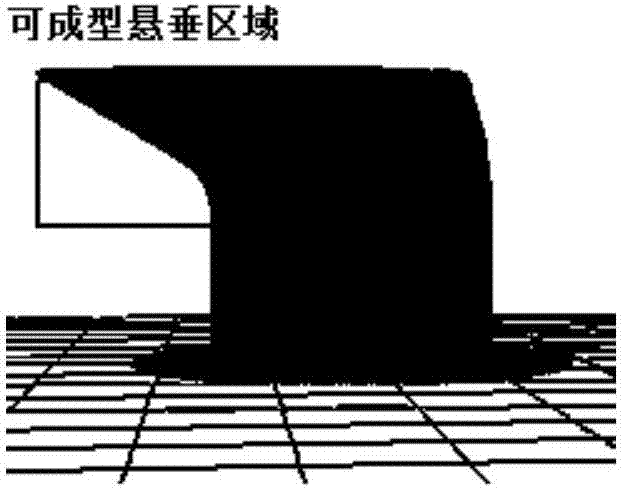

[0037] Step A2: Perform layered slicing processing on the STL model to obtain a closed two-dimensional polygon contour layer. Each two-dimensional contour is composed of a series of intersecting line segments. According to the data information of each line segment obtained, the formable dangling segment in each two-dimensional contour polygon is judged;

[0038] Step A21: Obtain the total number of slice layers n and all slice plane height values Z of ...

PUM

Login to View More

Login to View More Abstract

Description

Claims

Application Information

Login to View More

Login to View More - R&D

- Intellectual Property

- Life Sciences

- Materials

- Tech Scout

- Unparalleled Data Quality

- Higher Quality Content

- 60% Fewer Hallucinations

Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2025 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com