Preparation method of high-performance sintered Nd-Fe-B flake magnets by water transfer printing

A high-performance NdFeB technology, which is applied in the field of water transfer printing to prepare high-performance sintered NdFeB sheet magnets, to achieve uniform distribution and high thickness consistency, improve the coercive force of the magnetic sheet, and improve the effect of industrialization

- Summary

- Abstract

- Description

- Claims

- Application Information

AI Technical Summary

Problems solved by technology

Method used

Image

Examples

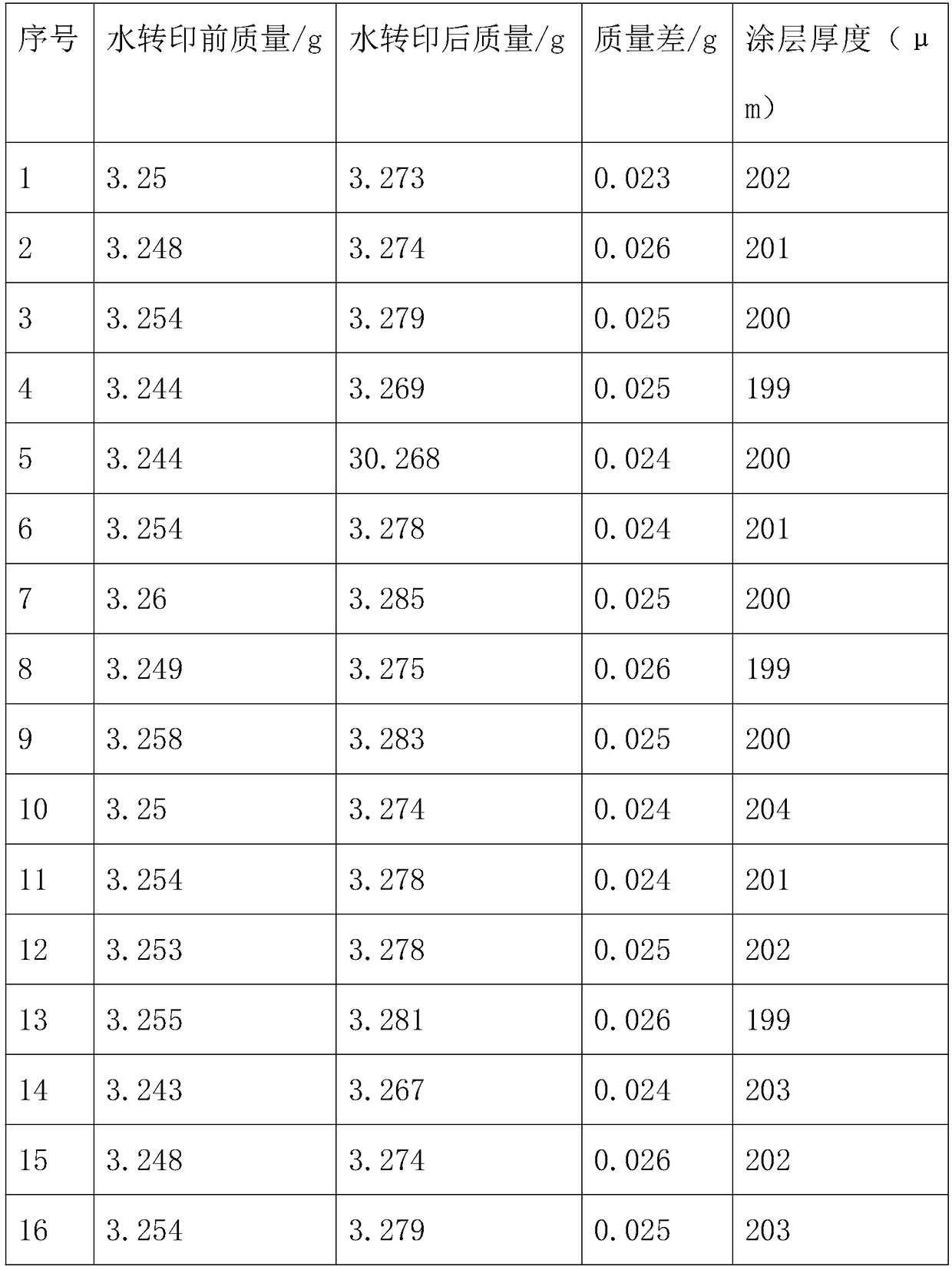

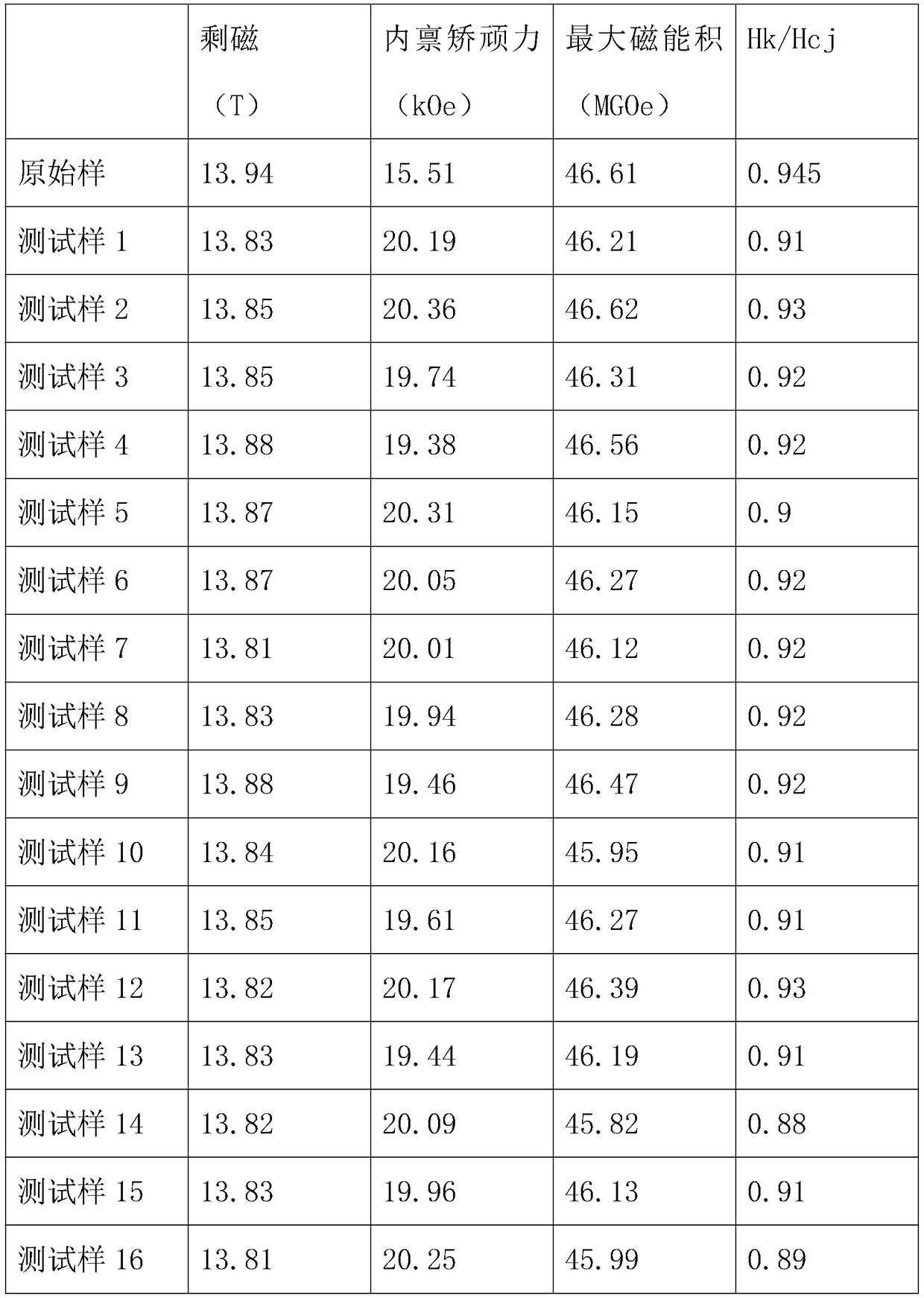

Embodiment 1

[0020] A method for preparing a high-performance sintered NdFeB sheet magnet by water transfer printing, comprising the following steps:

[0021] 1) Firstly, DyF powder with a particle size of ≤10 microns 3 The heavy rare earth compound powder is printed on the decal paper using 3D printing technology;

[0022] 2) Then soak the flower paper in water for 30s, and paste it on the pretreated sintered NdFeB sheet magnet to obtain a coating. The surface of the magnet is pretreated by using Na 3 PO 4 、Na 2 CO 3 , NaOH, OP-10 mixed solution as the base, adjust the pH with formic acid, ultrasonically clean at 70°C for 2 minutes to remove oil, then pickle with a mixture of nitric acid, thiourea and sodium lauryl sulfate, and then deionize obtained by ultrasonic cleaning of water;

[0023] 3) Then wipe off the water and carry out drying treatment. The drying treatment process is to keep warm at 80 ° C for 1 hour, and the sintered NdFeB thin-sheet magnets after drying treatment are ...

Embodiment 2

[0033] A method for preparing a high-performance sintered NdFeB sheet magnet by water transfer printing, comprising the following steps:

[0034] 1) Firstly, DyF powder with a particle size of ≤10 microns 3 The heavy rare earth compound powder is printed on the decal paper using 3D printing technology;

[0035]2) Then soak the flower paper in water for 30s, and paste it on the pretreated sintered NdFeB thin sheet magnet to obtain a coating. The surface pretreatment of the magnet is the same as that in Example 1.

[0036] 3) Then wipe off the moisture and carry out drying treatment. The drying treatment process is to keep warm at 120 ° C for 1 hour, and the sintered NdFeB thin-sheet magnets after drying treatment are stored in an inert gas environment;

[0037] 4) After drying, the sintered NdFeB thin film magnet is -3 Diffusion treatment and aging treatment were carried out in an inert gas environment of Pa, the temperature of diffusion treatment was 900°C, and the time was ...

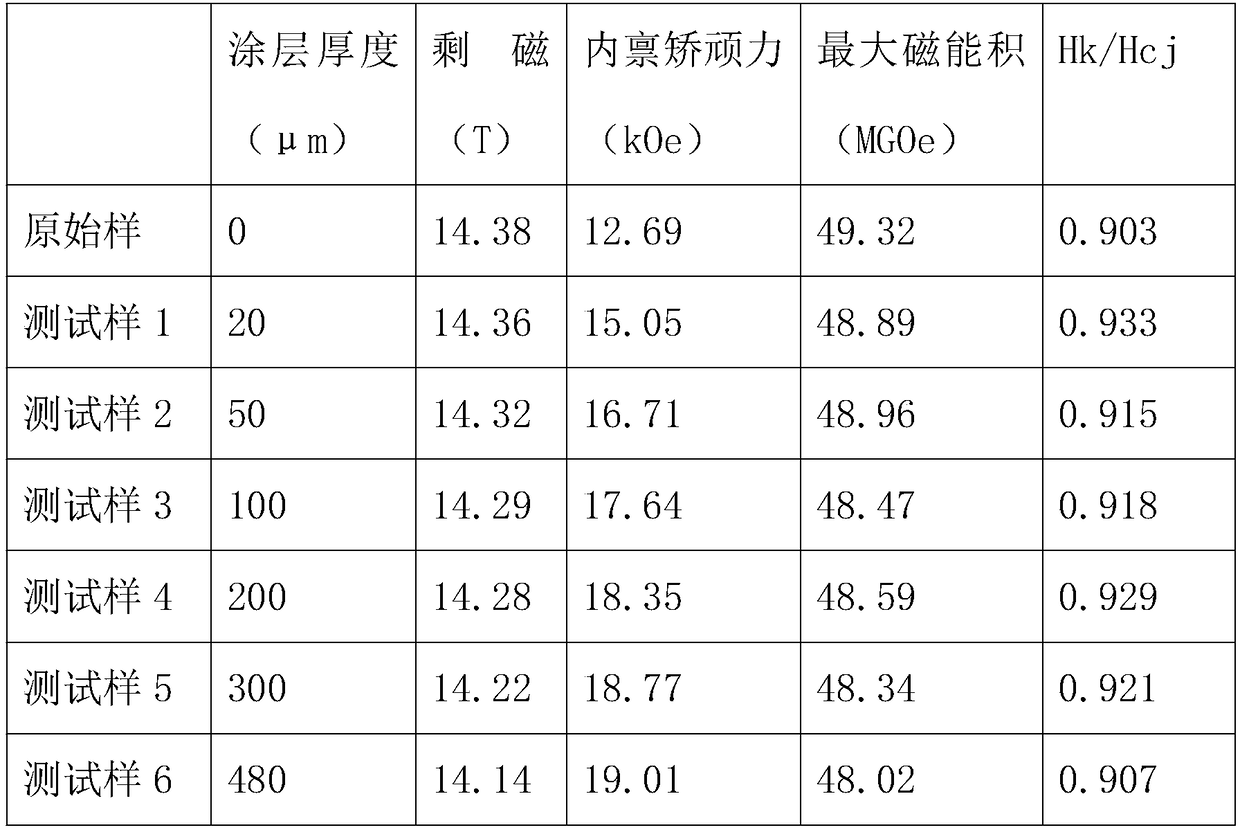

Embodiment 3

[0044] A method for preparing a high-performance sintered NdFeB sheet magnet by water transfer printing, comprising the following steps:

[0045] 1) First, powder DyH with a particle size of ≤10 microns 3 The heavy rare earth compound powder is printed on the decal paper using 3D printing technology;

[0046] 2) Then soak the flower paper in water for 30s, and paste it on the pretreated sintered NdFeB thin sheet magnet to obtain a coating. The surface pretreatment of the magnet is the same as that in Example 1.

[0047] 3) Then wipe off the water and carry out drying treatment. The drying treatment process is to keep warm at 110 ° C for 1 hour, and the sintered NdFeB thin-sheet magnet after drying treatment is stored in an inert gas environment;

[0048] 4) After drying, the sintered NdFeB thin film magnet is -3 Diffusion treatment and aging treatment were carried out in an inert gas environment of Pa, the temperature of diffusion treatment was 1100°C, and the time was 4h; t...

PUM

| Property | Measurement | Unit |

|---|---|---|

| particle size | aaaaa | aaaaa |

| thickness | aaaaa | aaaaa |

| thickness | aaaaa | aaaaa |

Abstract

Description

Claims

Application Information

Login to View More

Login to View More - R&D

- Intellectual Property

- Life Sciences

- Materials

- Tech Scout

- Unparalleled Data Quality

- Higher Quality Content

- 60% Fewer Hallucinations

Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2025 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com