Gas inlet structure and gas inlet method of chemical vapor deposition equipment and equipment

A technology of chemical vapor deposition and air intake structure, applied in chemical instruments and methods, from chemically reactive gases, crystal growth, etc., can solve the problems of product quality decline, difference in growth rate of silicon wafers, and poor consistency of silicon wafer thickness, etc. Achieve the effect of improving thickness consistency, improving product yield, and ensuring consistency

- Summary

- Abstract

- Description

- Claims

- Application Information

AI Technical Summary

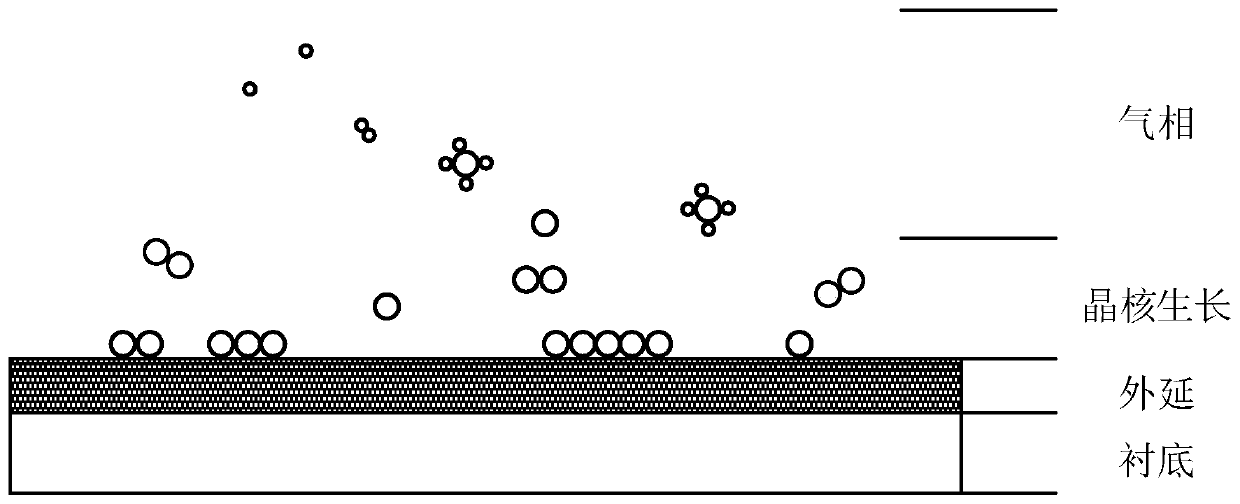

Problems solved by technology

Method used

Image

Examples

Embodiment Construction

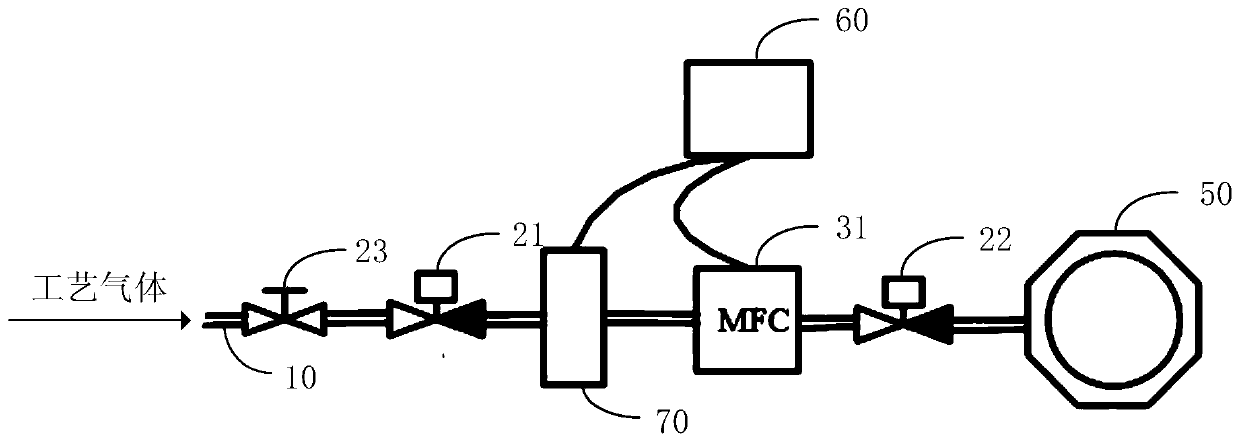

[0040] In order to enable those skilled in the art to better understand the technical solution of the present invention, the intake structure, intake method and chemical vapor deposition equipment of the chemical vapor deposition equipment provided by the present invention will be described in detail below with reference to the accompanying drawings.

[0041] Such as image 3 As shown, the first embodiment of the present invention provides an air inlet structure for chemical vapor deposition equipment. The intake structure includes an intake pipeline 10, which is used to transport process gas into the reaction chamber 50 of the chemical vapor deposition equipment.

[0042] In this embodiment, the process gas includes a source gas and a carrier gas, which are a mixed gas of the two. The source gas is a gas that undergoes a chemical reaction in the reaction chamber, and the carrier gas is a gas that carries the source gas into the reaction chamber but does not undergo a chemica...

PUM

Login to View More

Login to View More Abstract

Description

Claims

Application Information

Login to View More

Login to View More - R&D

- Intellectual Property

- Life Sciences

- Materials

- Tech Scout

- Unparalleled Data Quality

- Higher Quality Content

- 60% Fewer Hallucinations

Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2025 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com