Control device for automatic and quantitative paste feeding to lead storage battery coating plate

A technology of lead-acid battery and control device, which is applied in the direction of lead-acid battery, lead-acid battery electrode, lead-acid battery construction, etc. It can solve problems such as excessive assembly pressure, end of life, and shortened battery life, so as to avoid arbitrariness and prolong battery life. Effect of service life and weight improvement

- Summary

- Abstract

- Description

- Claims

- Application Information

AI Technical Summary

Problems solved by technology

Method used

Image

Examples

Embodiment Construction

[0012] In order to make the technical means, creative features, goals and effects achieved by the present invention easy to understand, the present invention will be further described below in conjunction with specific illustrations.

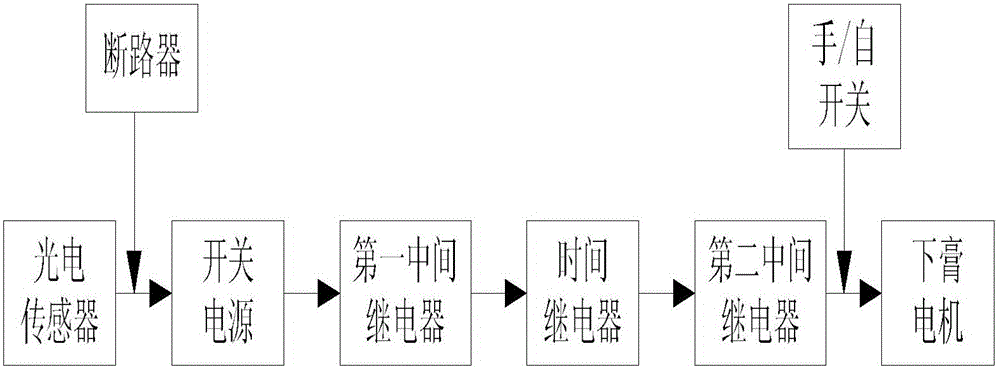

[0013] During specific implementation, combined with figure 1 , a kind of lead-acid storage battery coating automatic quantitative paste control device, including photoelectric sensor, switching power supply, first intermediate relay, time relay, second intermediate relay, paste motor, photoelectric sensor, switching power supply, first intermediate relay, time The relay, the second intermediate relay and the paste-discharging motor are connected in sequence, a circuit breaker is connected between the photoelectric sensor and the switching power supply, and a switch is connected between the second intermediate relay and the paste-discharging motor. The photoelectric sensor may be a specular reflective photoelectric sensor. The switch can be a m...

PUM

Login to View More

Login to View More Abstract

Description

Claims

Application Information

Login to View More

Login to View More - R&D

- Intellectual Property

- Life Sciences

- Materials

- Tech Scout

- Unparalleled Data Quality

- Higher Quality Content

- 60% Fewer Hallucinations

Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2025 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com